Novel vertical multistage pump

A multi-stage pump, vertical technology, applied in the direction of non-variable pumps, non-volume pumps, pumps, etc., can solve the problems of unfavorable pump normal operation, large load pressure, high working pressure, etc., to improve the reliability of use Improvement of performance and service life, improvement of pump efficiency, and reduction of axial force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

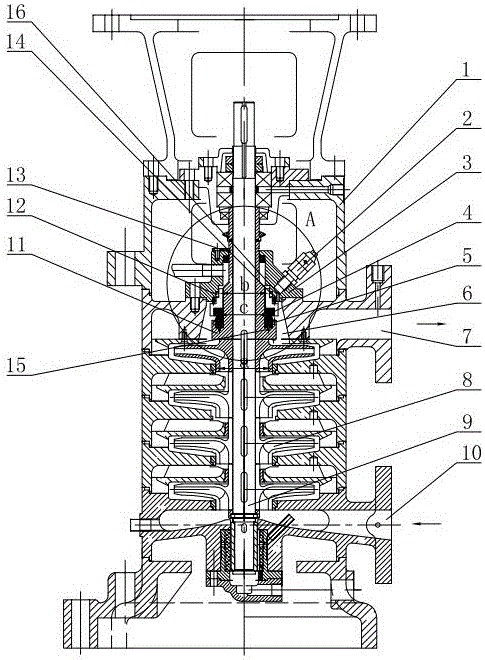

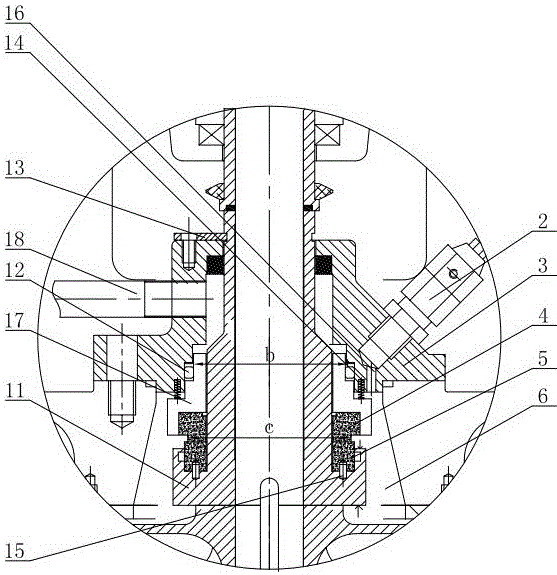

[0019] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0020] Such as figure 1 and figure 2 As shown, the novel vertical multistage pump of this embodiment includes a pump housing 1, a pump shaft 9 is installed in the pump housing 1, a plurality of impellers 8 are installed on the pump shaft 9, and the inlet pressure of each impeller 8 is Less than the outlet pressure, a semi-packaged mechanical seal is installed on the pump shaft 9 at the top of the impeller 8. The structure of the semi-packaged mechanical seal is: including a mechanical seal shaft sleeve 11, which is provided with a card slot. The inside of the card slot is inlaid with the moving ring 5 through the anti-rotation pin 15; the mechanical seal shaft sleeve 11 is covered with a static ring seat 17 on the outer circumferential surface above the moving ring 5, and the bottom of the static ring seat 17 has a groove, and the groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com