Building method for open caisson for underground garage

A construction method and technology for underground garages, which are applied to caissons, buildings, underwater structures, etc., can solve the problems of increasing the maintenance work of the underground structure in the later stage, increasing the maintenance cost of the caisson, and high cost, so as to ensure the connection strength and waterproof performance, The construction process is simple and easy to control, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

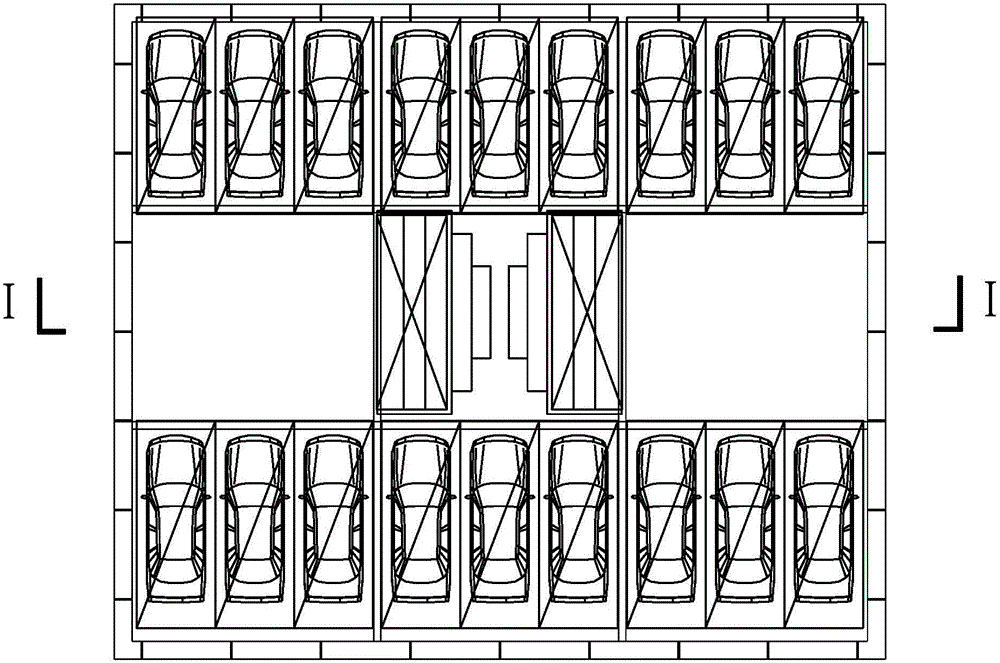

[0094] see figure 1 and figure 2 , the horizontal section of the underground garage in this embodiment is rectangular, where figure 2 Shown only as an example is the parking platform on one of the floors of the garage where vehicles are parked. The caisson of the underground garage is composed of a shaft wall and a frame installed in the shaft wall. The shaft wall adopts a steel-concrete structure. The shaft wall is specifically divided into three shafts. The third wellbore section, each wellbore section includes 32 steel-concrete structure segments, specifically 4 L-shaped positioning segments and 28 flat plate-shaped assembly segments. The frame is made of steel members, including interconnected horizontal beams and columns, and the frame acts as both the internal support of the caisson and the support frame of the parking platform. In this embodiment, the segments are plate-shaped and have two vertical longitudinal end faces; two adjacent segment segments in the horizo...

Embodiment 2

[0138] This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the locking part is made of a linear steel sheet pile with a lock. For the convenience of description, the locking part of the segment 55 is called E locking The locking portion of the segment 56 is referred to as the F locking portion.

[0139] see Figure 22 and Figure 23 , Two E-locking portions 551 are provided on the longitudinal end surface 555 of the tube piece 55 ; two F-locking portions 561 are provided on the longitudinal end surface 565 of the tube piece 56 . Both the E locking part 551 and the F locking part 561 are made of linear steel sheet piles. Specifically, the linear steel sheet piles are cut in half along the center line of the web, and then cut to form several half-width linear steel sheet piles, and then the One end of the web plate of the semi-linear steel sheet pile is buried in the assembly segment, and the end with the lock protrudes from the long...

Embodiment 3

[0144] This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment, the locking part is made of U-shaped steel sheet piles with locks, and the longitudinal end faces of the segments are planes, and each longitudinal end face is provided with A closure.

[0145] see Figure 25 , the locking part 63 is made of U-shaped steel sheet piles. Specifically, the U-shaped steel sheet piles are cut in half along the center line of the web, and then cut off to form several half-width U-shaped steel sheet piles, and then the webs of the half-width U-shaped steel sheet piles are One end of the plate is buried in the assembly segment, and the end with the lock protrudes from the longitudinal end surface.

[0146] Weld the water-stop steel plate 64 at the locked joint, and pour fine stone concrete 65 between the two left and right adjacent segments.

[0147] It can be understood that only the U-shaped steel sheet pile can be truncated along the length di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com