An anti-aging, anti-corrosion, anti-bacterial and anti-fouling oil agent for polyester fiber

An anti-corrosion and anti-bacterial polyester fiber technology, which is applied in the fields of anti-corrosion, anti-bacterial, anti-fouling oil agents and anti-aging, can solve the problems of not being able to satisfy the use of seawater-resistant materials, and achieve easy industrial production and application, good anti-fouling effect, and wide improvement spectral effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

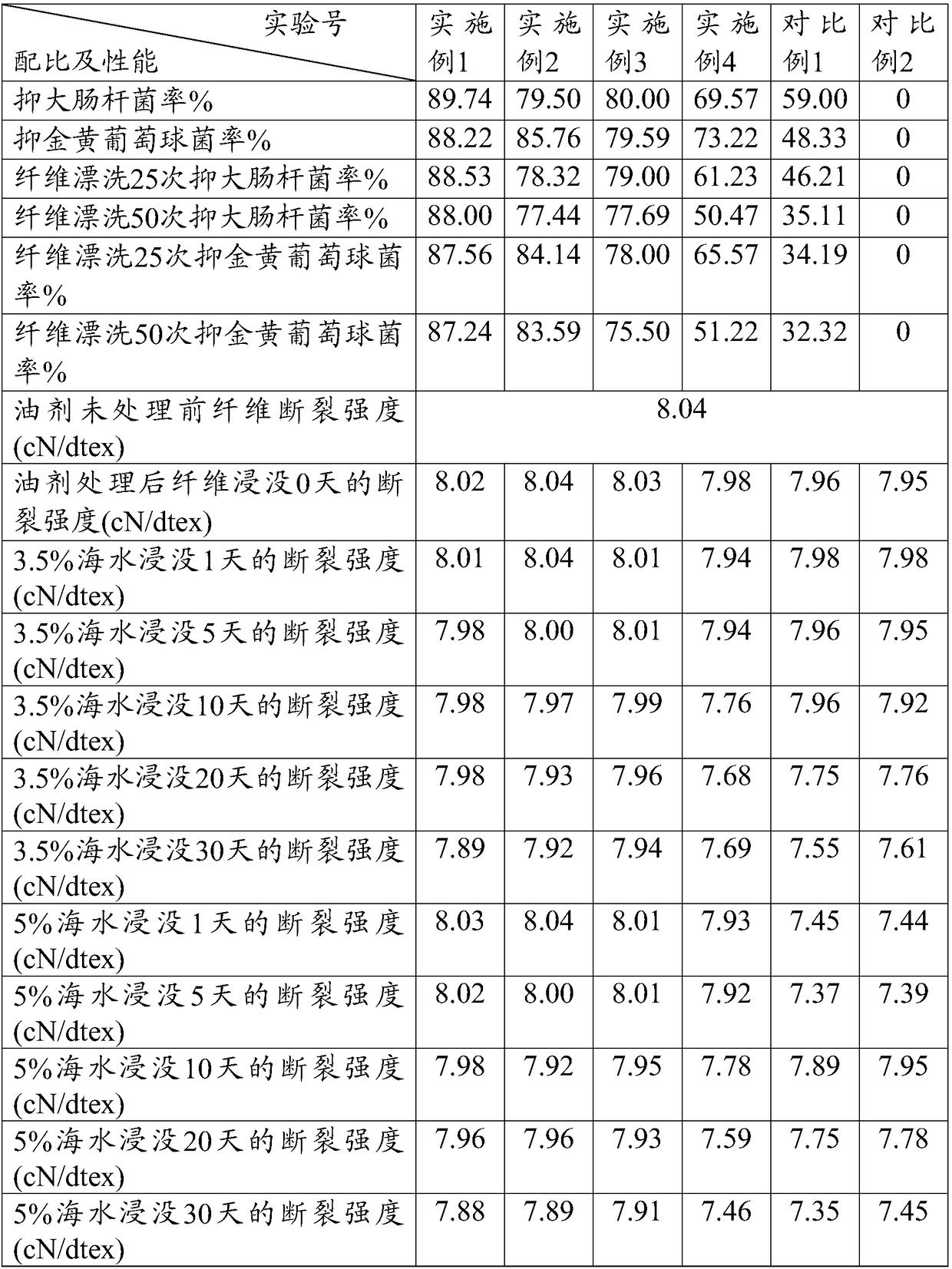

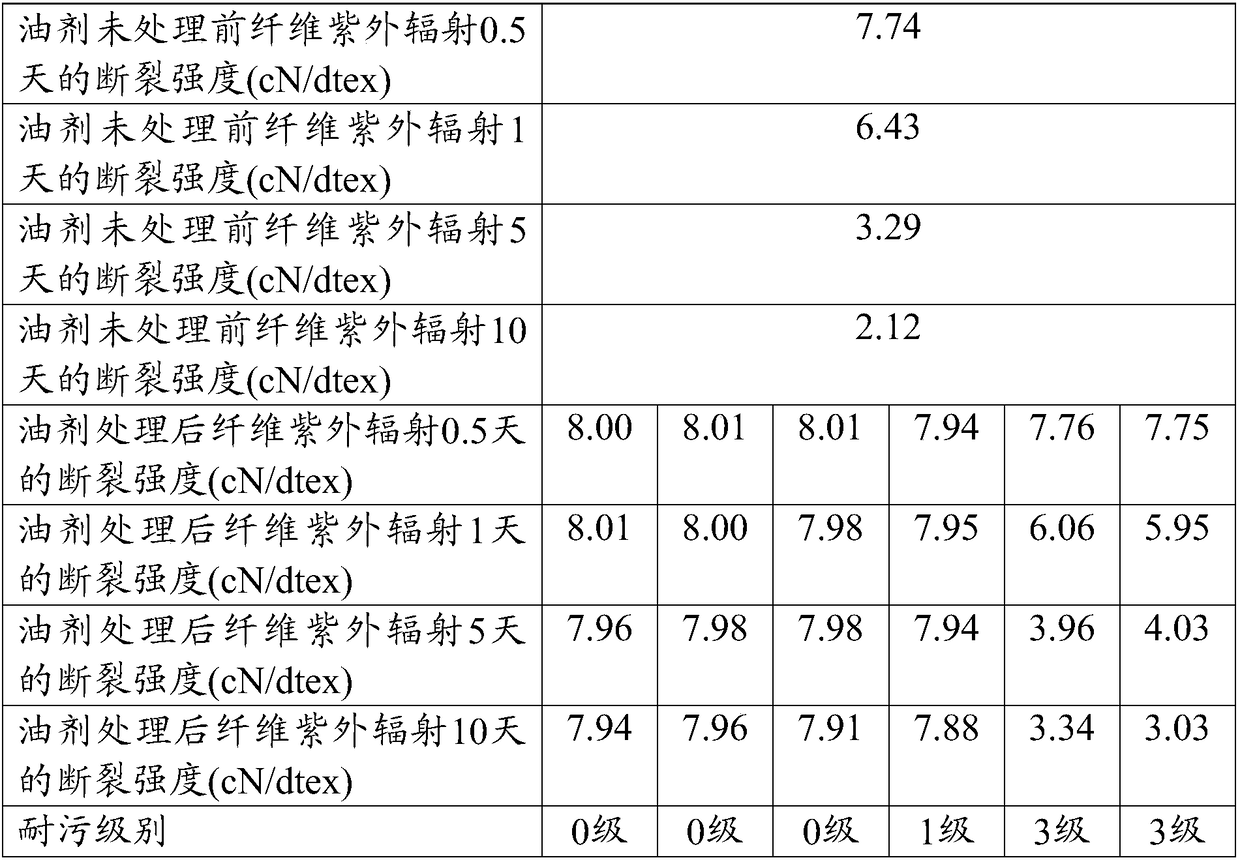

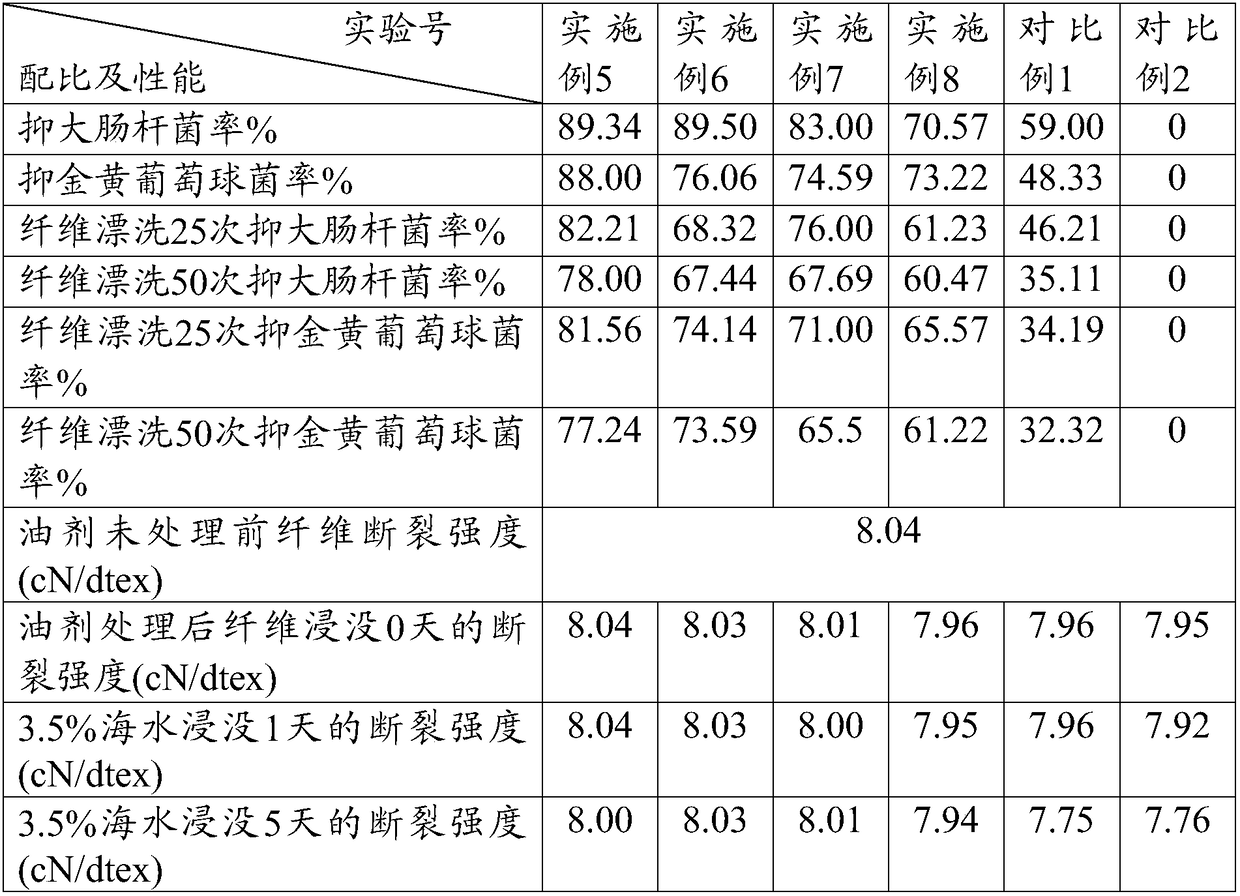

Examples

Embodiment 1

[0029] The formulation of anti-aging, anti-corrosion, anti-bacterial and anti-fouling oil agent for polyester fiber: penta-copolymer block silicone oil accounts for 28.6 parts, diisononyl phthalate accounts for 2.9 parts, and nonylphenol polyoxyethylene ether accounts for 1.9 parts , Polyquaternium-11 accounts for 1.9 parts, zinc oxide sol accounts for 3.8 parts, distilled water accounts for 47.6 parts, polyoxyethylene ether accounts for 8.6 parts, and dispersant KF60 accounts for 4.7 parts.

Embodiment 2

[0031] The formulation of anti-aging, anti-corrosion, anti-bacterial and anti-fouling oil agent for polyester fiber: penta-copolymer block silicone oil accounts for 28.6 parts, diisononyl phthalate accounts for 2.9 parts, and nonylphenol polyoxyethylene ether accounts for 1.9 parts , Polyquaternium-11 accounts for 1.4 parts, zinc oxide sol accounts for 4.3 parts, distilled water accounts for 47.6 parts, polyoxyethylene ether accounts for 8.6 parts, and dispersant KF60 accounts for 4.7 parts.

Embodiment 3

[0033] The formulation of anti-aging, anti-corrosion, anti-bacterial and anti-fouling oil agent for polyester fiber: penta-copolymer block silicone oil accounts for 28.6 parts, diisononyl phthalate accounts for 2.9 parts, and nonylphenol polyoxyethylene ether accounts for 1.9 parts , Polyquaternium-11 accounts for 3.8 parts, zinc oxide sol accounts for 1.9 parts, distilled water accounts for 47.6 parts, polyoxyethylene ether accounts for 8.6 parts, and dispersant KF60 accounts for 4.7 parts.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com