Magnetron sputtering planar target material shield cover

A technology of magnetron sputtering and shielding cover, applied in sputtering coating, metal material coating process, ion implantation coating, etc., can solve the problems of waste of resources, high production cost, ignition or short circuit, etc., and achieve The effect of keeping the distance between them stable, reducing the phenomenon of sparking, and reducing the frequency of occurrence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

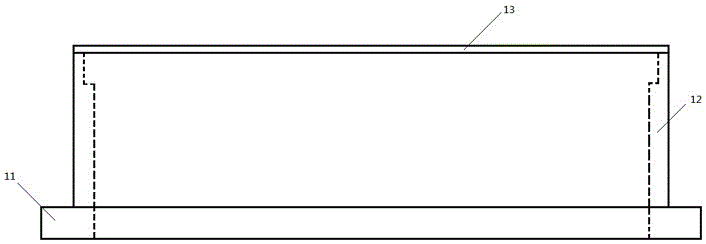

[0030] combined with figure 1 , The magnetron sputtering planar target shielding cover includes a target back plate 11, a shielding cover, surrounding side baffles 12, an upper cover plate 13, and fixing screws. The surrounding side baffles 12 are an integral structure, and the upper cover plate 13 is also an integral structure. The surrounding side baffles 12 are fixed on the target back plate 11 by screws, and a gap is left on the upper side of the surrounding side baffle 12 to ensure that particles and impurities generated during the sputtering process leak through the gaps. The lower edge of the notch is kept at the same height as the upper surface of the cathode target inside the surrounding side baffle 12. After the installation of the surrounding side baffle 12, the distance between it and the side of the internal cathode target should be 0.1-0.5 cm, preferably 0.2 cm. The distance between the side baffle at the upper position and the side of the cathode target is 0.3-...

Embodiment 2

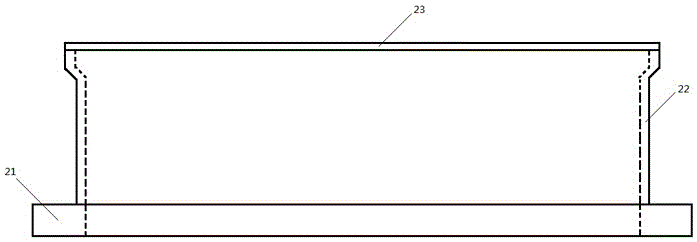

[0032] combined with figure 2 , the magnetron sputtering planar target shielding cover includes a target back plate 21, a shielding cover, surrounding side baffles 22, an upper cover plate 23, and fixing screws. The surrounding side baffles 22 are an integral structure, and the upper cover plate 23 is also an integral structure. The surrounding side baffles 22 are fixed on the target back plate 21 by screws, and a gap is left on the upper side of the surrounding side baffle 22 to ensure that particles and impurities generated during the sputtering process leak through the gaps. The lower edge of the notch is kept at the same height as the upper surface of the cathode target inside the surrounding side baffle 22. After the surrounding side baffle 22 is installed, the distance between it and the side of the internal cathode target should be 0.1-0.5 cm, preferably 0.2 cm. The distance between the side baffle at the upper position and the side of the cathode target is 0.3-1cm. ...

Embodiment 3

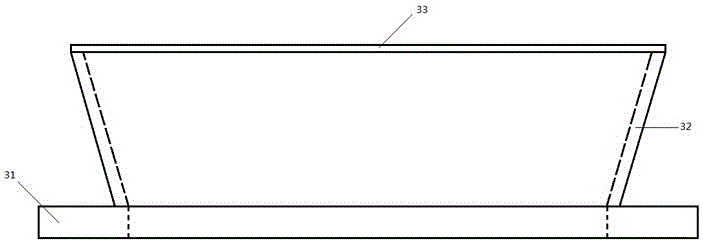

[0034] combined with image 3 , the magnetron sputtering planar target shielding cover includes a target back plate 31, a shielding cover, surrounding side baffles 32, an upper cover plate 33, and fixing screws. The surrounding side baffles 32 are an integral structure, and the upper cover plate 33 is also an integral structure. The surrounding side baffles 32 are fixed on the target back plate 31 by screws, and a gap is left on the upper side of the surrounding side baffles 32 to ensure that particles and impurities generated during the sputtering process leak through the gaps. The lower edge of the notch is kept at the same height as the upper surface of the cathode target inside the surrounding side baffle 32. After the installation of the surrounding side baffle 32, the distance between it and the side of the internal cathode target should be 0.1-0.5 cm, preferably 0.2 cm. The distance between the side baffle at the upper position and the side of the cathode target is 0.3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com