Expansion casing for heavy oil thermal recovery well and manufacturing method thereof

A technology for expansion casing and thermal recovery of heavy oil, which is applied in the direction of casing, drill pipe, earthwork drilling, etc., can solve the problems of material plastic toughness reduction, high temperature strength reduction, etc., to improve toughness, strength, and grain refinement grain effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

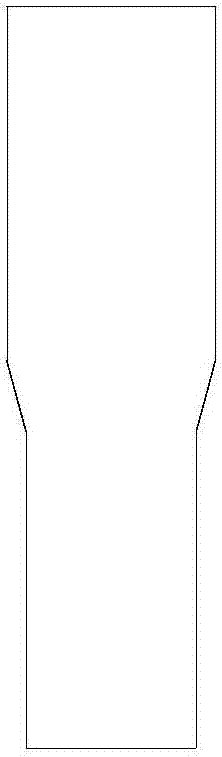

Image

Examples

Embodiment Construction

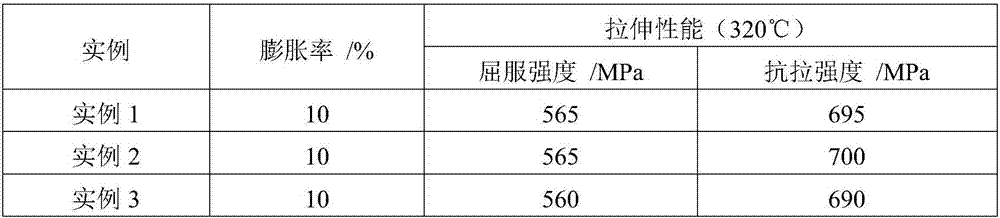

[0021] Examples are shown in Table 1-Table 3. It can be seen from Table 1-Table 3 that: adopting the chemical composition and process described in the present invention, the expansion performance of the expansion casing for the test heavy oil thermal recovery well produced is excellent, and the pipe still has high strength after radial expansion and deformation. Good toughness and good high-temperature mechanical properties can meet the performance requirements of N80 steel grade casing in API5CT standard.

[0022] The three embodiments all use the molten steel smelted in an electric furnace and refined outside the furnace to be cast into slabs after being treated with Ca. The slab is heated at 1160-1280°C and rolled into a strip. The final rolling temperature of the strip is higher than 830°C. After rolling, the strip is cooled to below 660°C by accelerated cooling and coiled into a coil. After decoiling, slitting, edge milling, FFX forming, HFW welding and weld heat treatme...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com