A kind of low fermentation degree turbid wheat dry beer and its brewing method

A low-fermentation and turbid technology, applied in the field of fermented food processing, can solve the problems of poor solubility of gluten and application limitations, and achieve the effects of rich and harmonious yeast aroma, low alcohol content and turbid wine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

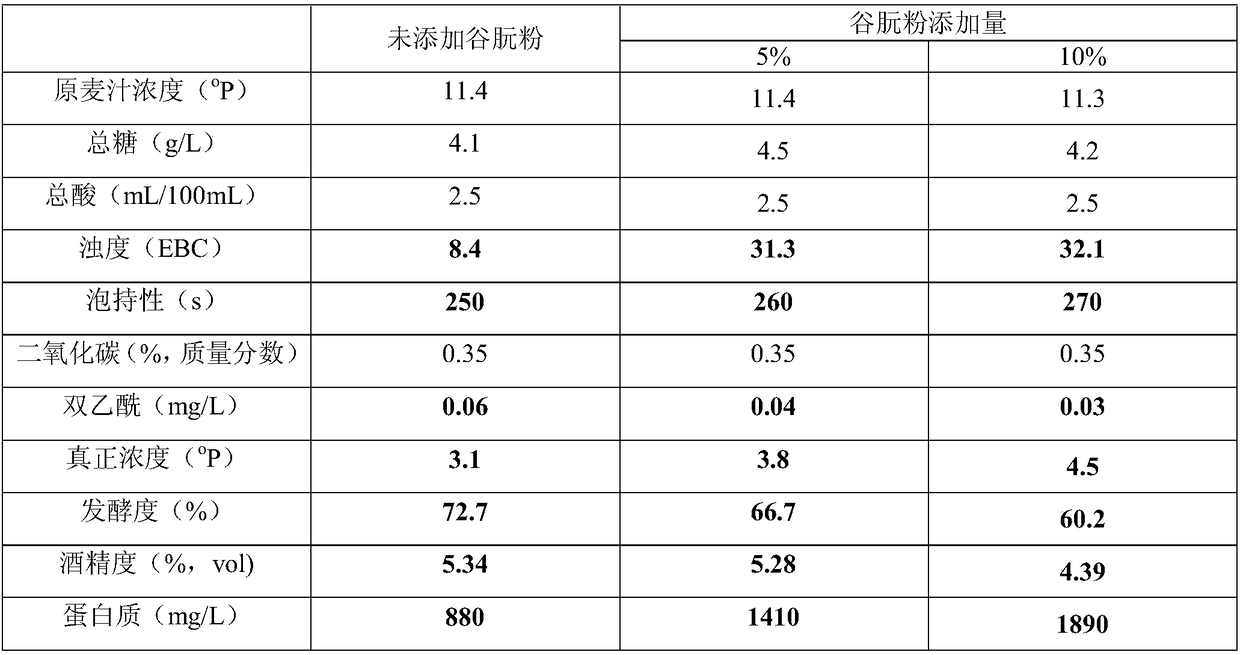

Embodiment 1

[0019] 1. Wort preparation

[0020] Beer barley malt and wheat malt are mixed in a mass ratio of 1:1, crushed, based on the total mass of the beer barley malt and wheat malt mixture as 100%, water is added until the total material water is 1:4 (m / m), and high temperature resistant 0.01% (m / m) of α-amylase was used for saccharification to prepare wort. The initial saccharification temperature was 45°C, the heating rate was 1°C / min, the protein resting temperature was 55°C, the saccharification temperature was 63°C, the liquefaction temperature was 72°C, and the liquefaction end point was 20 minutes after the iodine reaction disappeared. Filtration and washing at a temperature of 80°C. Add hop granules in an amount of 1.5g / L, boil at 100°C for 45 minutes, cool to 16°C, and inject sterile air until the dissolved oxygen content of the wort is 8.7mg / L to obtain the shaped wort.

[0021] 2. Fermentation

[0022] According to the mass ratio of beer yeast and shaped wort above as 1...

Embodiment 2

[0025] 1. Preparation of gluten emulsion

[0026] Wheat gluten and sodium hydroxide aqueous solution (1.5%, m / m) are mixed evenly at a mass ratio of 1:6, heated to boiling, kept at 90°C for 10 hours, and centrifuged to remove the precipitate to obtain a uniform gluten emulsion, which is used Lactic acid adjusts the pH value of the gluten emulsion to 6.0 and sets aside.

[0027] 2. Wort preparation

[0028] Beer barley malt and wheat malt are mixed in a mass ratio of 1:1, crushed, and the total mass of the beer barley malt and wheat malt mixture is taken as 100%, and the gluten emulsion prepared in step 1) is added thereto, and the addition amount is expressed in grains Gluten powder accounts for 5% of the total amount of malt mixture, then add water until the total material-water ratio is 1:4 (m / m), add 0.01% (m / m) of high-temperature-resistant α-amylase and protease for saccharification to prepare wort . The initial saccharification temperature was 45°C, the heating rate w...

Embodiment 3

[0034] 1. Preparation of gluten emulsion

[0035] Wheat gluten and sodium hydroxide aqueous solution (1.5%, m / m) are mixed evenly at a mass ratio of 1:6, heated to boiling, kept at 90°C for 10 hours, and centrifuged to remove the precipitate to obtain a uniform gluten emulsion, which is used Lactic acid adjusts the pH value of the gluten emulsion to 6.0 and sets aside.

[0036] 2. Wort preparation

[0037] Beer barley malt and wheat malt are mixed in a mass ratio of 1:1, crushed, and the total mass of the beer barley malt and wheat malt mixture is taken as 100%, and the gluten emulsion prepared in step 1) is added thereto, and the addition amount is expressed in grains Gluten powder accounts for 10% of the total amount of malt mixture, then add water until the total material-water ratio is 1:4 (m / m), add 0.01% (m / m) of high-temperature-resistant α-amylase and protease for saccharification to prepare wort . The initial saccharification temperature was 45°C, the heating rate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com