Energy-saving type soap making system

A soap-making system and energy-saving technology, which is applied in the direction of forming soap, soap solution manufacturing, mixing/kneading soap, etc., to achieve the effect of reducing soap base drying process, reducing energy consumption, and mixing uniformly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

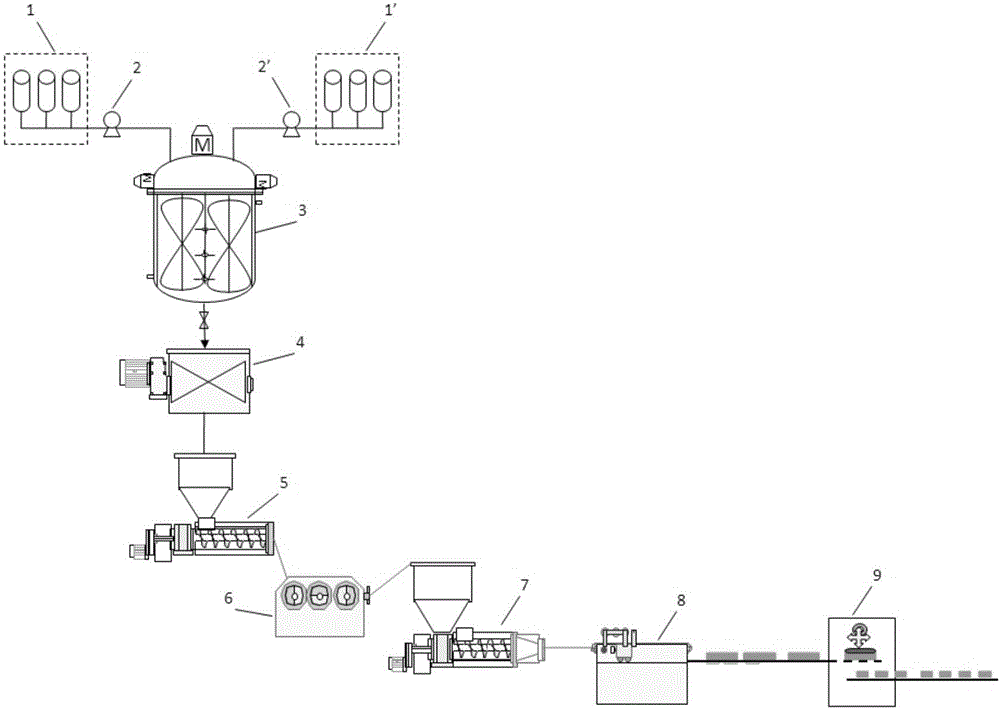

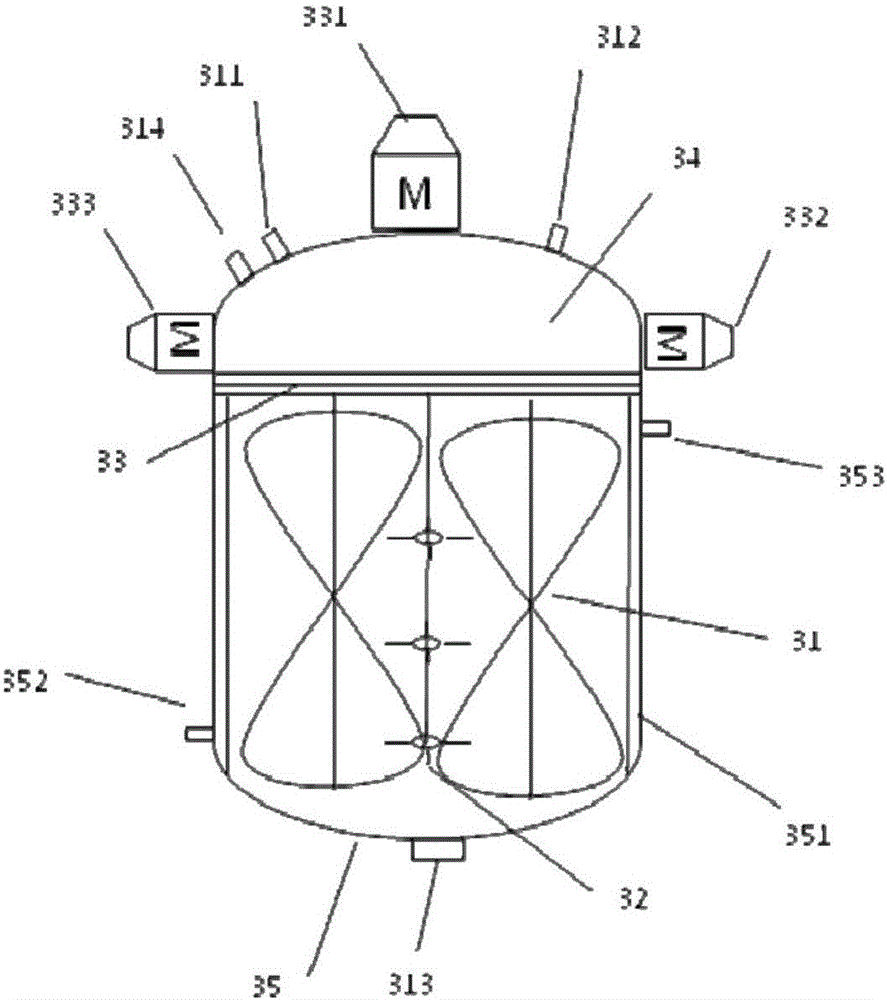

[0041] Such as figure 1 As shown, the structure of the energy-saving soap-making system of the embodiment of the present invention mainly includes: a metering and feeding device, a neutralization reactor and a finished soap production device connected in sequence. The metering feeding device includes two sets, one of which is composed of the first raw material storage tank group 1 and the first metering pump 2, the outlet of the first metering pump 2 is connected with the inlet pipe of the neutralization reactor 3; the other set is composed of the second The raw material storage tank group 1' is composed of a second metering pump 2', and the outlet of the second metering pump 2' is connected with the inlet pipe of the neutralization reactor 3. The first raw material storage tank group 1 includes a fatty acid storage tank and two auxiliary material storage tanks; the second raw material storage tank group 1' includes a liquid alkali tank, a process water tank and three auxiliar...

Embodiment 2

[0049] As shown in Fig. 2, the soap making system of another embodiment of the present invention mainly includes a structure of a metering and feeding device, a neutralization reactor and a finished soap production device connected in sequence. The metering feeding device includes two sets, one of which is composed of the first raw material storage tank group 1 and the first metering pump 2, the outlet of the first metering pump 2 is connected with the inlet pipe of the neutralization reactor 3; the other set is composed of the second The raw material storage tank group 1' is composed of a second metering pump 2', and the outlet of the second metering pump 2' is connected with the inlet pipe of the neutralization reactor 3.

[0050] The structure difference from Example 1 is: the first raw material storage tank group 1 includes a fatty acid storage tank and three auxiliary material storage tanks; the second raw material storage tank group 1' includes a liquid alkali tank, a pro...

Embodiment 3

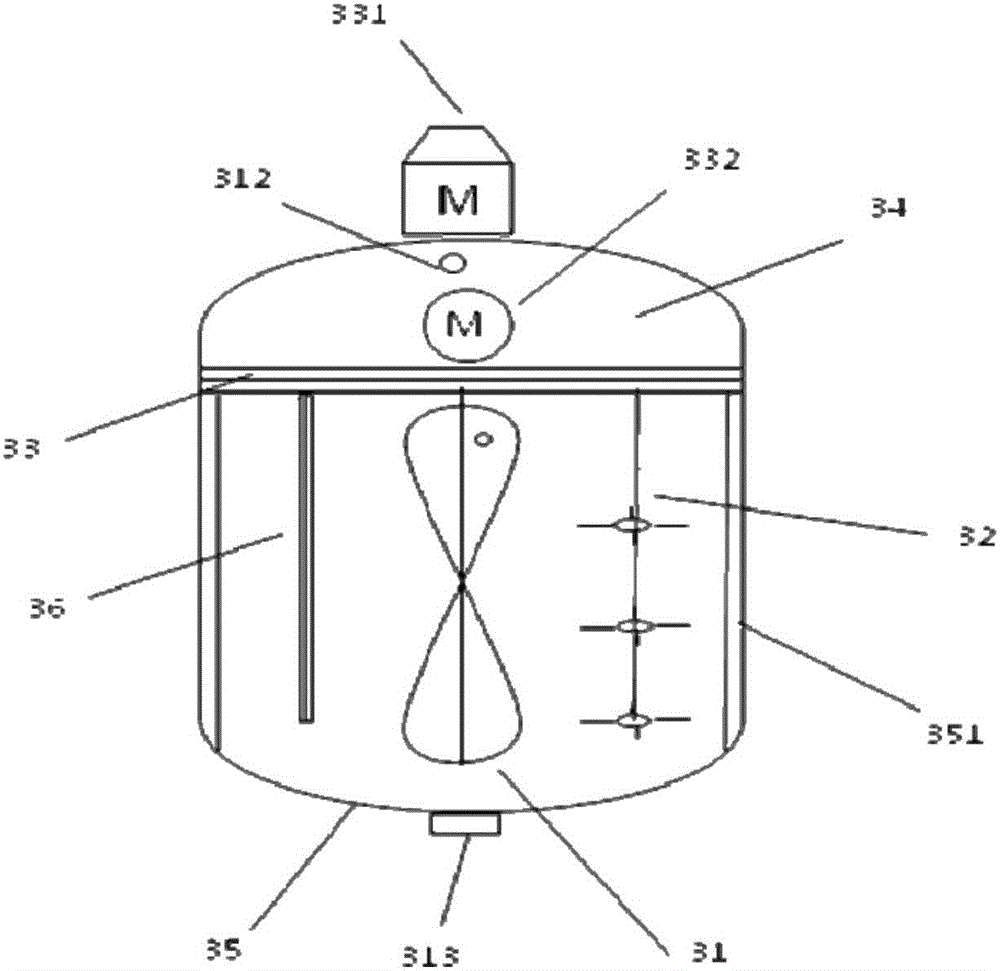

[0055] Such as image 3 Shown is the soap making system of another embodiment of the present invention. The soap making system includes: a metering and feeding device, a neutralization reactor and a finished soap production device connected in sequence. The metering feeding device includes two sets, one of which is composed of the first raw material storage tank group 1 and the first metering pump 2, the outlet of the first metering pump 2 is connected with the inlet pipe of the neutralization reactor 3; the other set is composed of the second The raw material storage tank group 1' is composed of a second metering pump 2', and the outlet of the second metering pump 2' is connected with the inlet pipe of the neutralization reactor 3. The first raw material storage tank group 1 includes a fatty acid storage tank and three auxiliary material storage tanks; the second raw material storage tank group 1' includes a liquid alkali tank, a process water tank and three auxiliary materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com