Preparation method of super absorbent polymer (SAP) with strong acid and alkali resistance

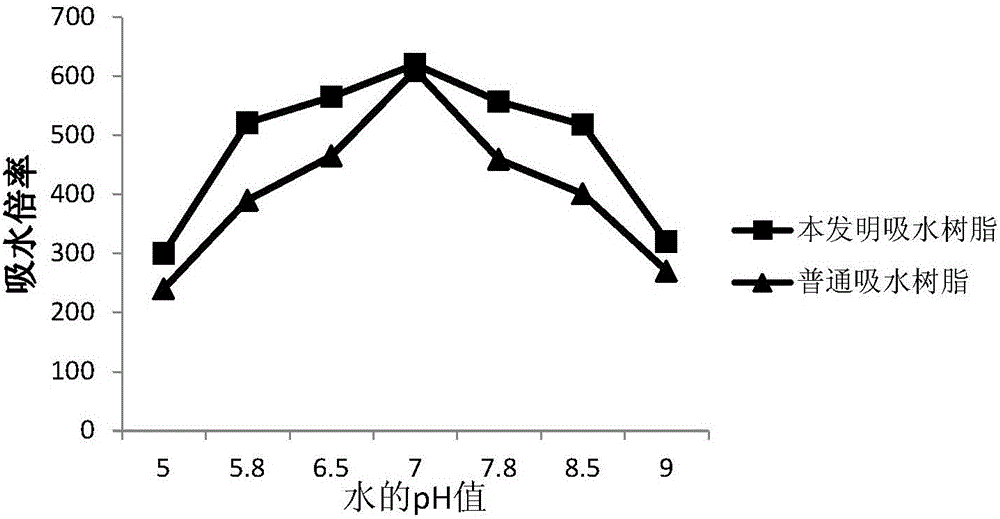

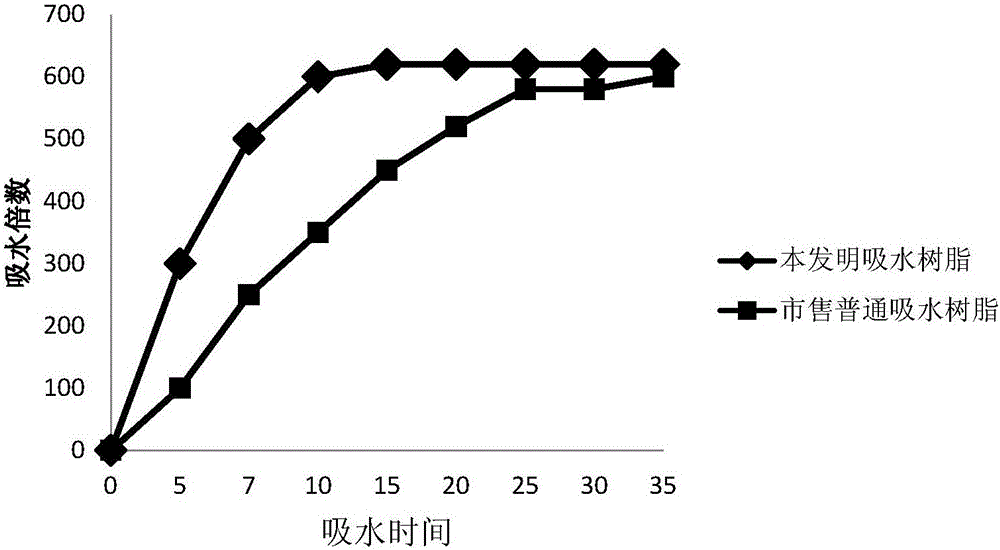

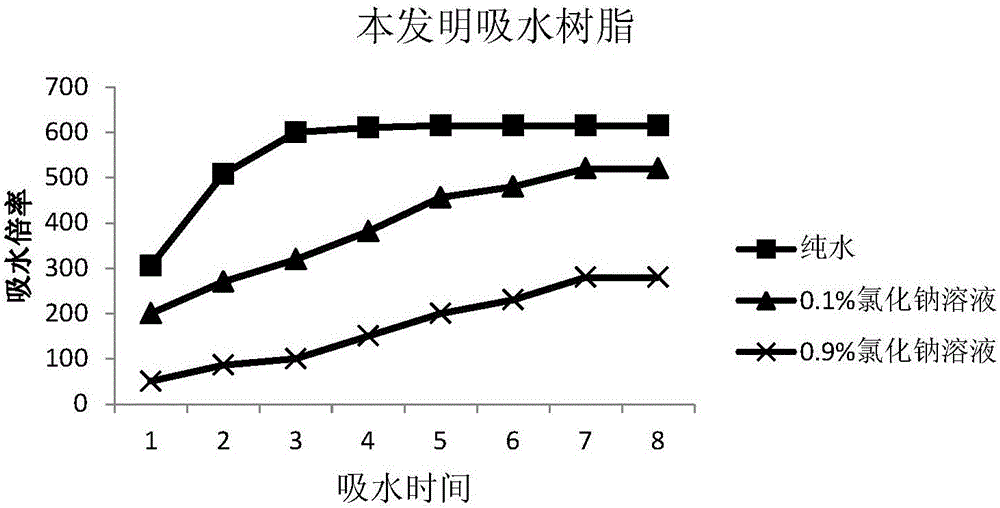

A technology of polymer water absorption, acid and alkali resistance, applied in chemical instruments and methods, applications, organic fertilizers, etc., can solve the problems of caking and water absorption ratios that are easily affected by soil pH, high product cost, and achieve faster water absorption. Strong resistance to acid and alkali, the effect of improving water absorption rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1. A preparation method of a high-molecular water-absorbing resin with strong acid and alkali resistance, the steps are as follows,

[0030] 50g acrylic acid is put into the 500ml reaction bottle that fills 300g water, add 50g potassium carbonate (K 2 CO 3 ) After the neutralization reaction is completed, the pH value reaches 6.8-7.2, and then 70g of acrylamide is added, stirred evenly and completely dissolved, and the measured pH value should be 7.0±0.1. Add 0.06 g of cross-linking agent hexamethylenetetramine under stirring, then add 2.38 g of phosphate buffer (2.04 g of potassium dihydrogen phosphate, 0.34 g of sodium hydroxide), then add 3 g of calcium carbonate, and stir evenly. Add 0.02g of sodium sulfite, stir evenly, and then add 0.02g of crosslinking agent. Blow nitrogen gas at 0-30°C for 0.5 hours to remove dissolved oxygen, and measure the dissolved oxygen in the system to be ≤0.01mg / L. If not, 0.02g of sodium sulfite can be added to further abs...

Embodiment 2

[0031] Embodiment 2. A preparation method of a polymer water-absorbent resin with strong acid and alkali resistance, the steps are as follows,

[0032] 30g acrylic acid is put into the 500ml reaction bottle that fills 300g water, add 30g potassium carbonate (K 2 CO 3 ) After the neutralization reaction is completed, the pH value reaches 6.8-7.2, then add 50g of acrylamide, stir evenly and dissolve completely, and the measured pH value should be 7.0±0.1. Add 0.04 g of cross-linking agent hexamethylenetetramine under stirring, then add 2.38 g of phosphate buffer (2.04 g of potassium dihydrogen phosphate, 0.34 g of sodium hydroxide), then add 4 g of starch, and stir evenly. Add 0.02g of sodium sulfite, stir evenly, and then add 0.02g of crosslinking agent. Blow nitrogen gas at 0-30°C for 0.5 hours to remove dissolved oxygen, and measure the dissolved oxygen in the system to be ≤0.01mg / L. If not, 0.02g of sodium sulfite can be added to further absorb dissolved oxygen. After 10...

Embodiment 3

[0033] Embodiment 3. A preparation method of a polymer water-absorbent resin with strong acid and alkali resistance, the steps are as follows,

[0034] 40g acrylic acid is put into the 500ml reaction bottle that fills 300g water, add 40g potassium carbonate (K 2 CO 3) After the neutralization reaction is completed, the pH value reaches 6.8-7.2, and then 60g of acrylamide is added, stirred evenly and completely dissolved, and the measured pH value should be 7.0±0.1. Add 0.05 g of cross-linking agent hexamethylenetetramine under stirring, then add 2.68 g of citric acid buffer (0.33 g of citric acid, 2.35 g of disodium hydrogen phosphate), then add 5 g of bentonite, and stir evenly. Add 0.02g of sodium sulfite, stir evenly, and then add 0.02g of crosslinking agent. Blow nitrogen gas at 0-30°C for 0.5 hours to remove dissolved oxygen, and measure the dissolved oxygen in the system to be ≤0.01mg / L. If not, 0.02g of sodium sulfite can be added to further absorb dissolved oxygen. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com