Method for removing arsenic ions in water through N element modified graphene electrode

A technology of graphene electrodes and arsenic ions, which is applied in the direction of separation methods, chemical instruments and methods, water pollutants, etc., can solve problems affecting the performance of graphite, etc., and achieve the effects of simple operation, short time, and simple and easy preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The preparation of nitrogen-doped hydrogel material paper electrode includes the following steps:

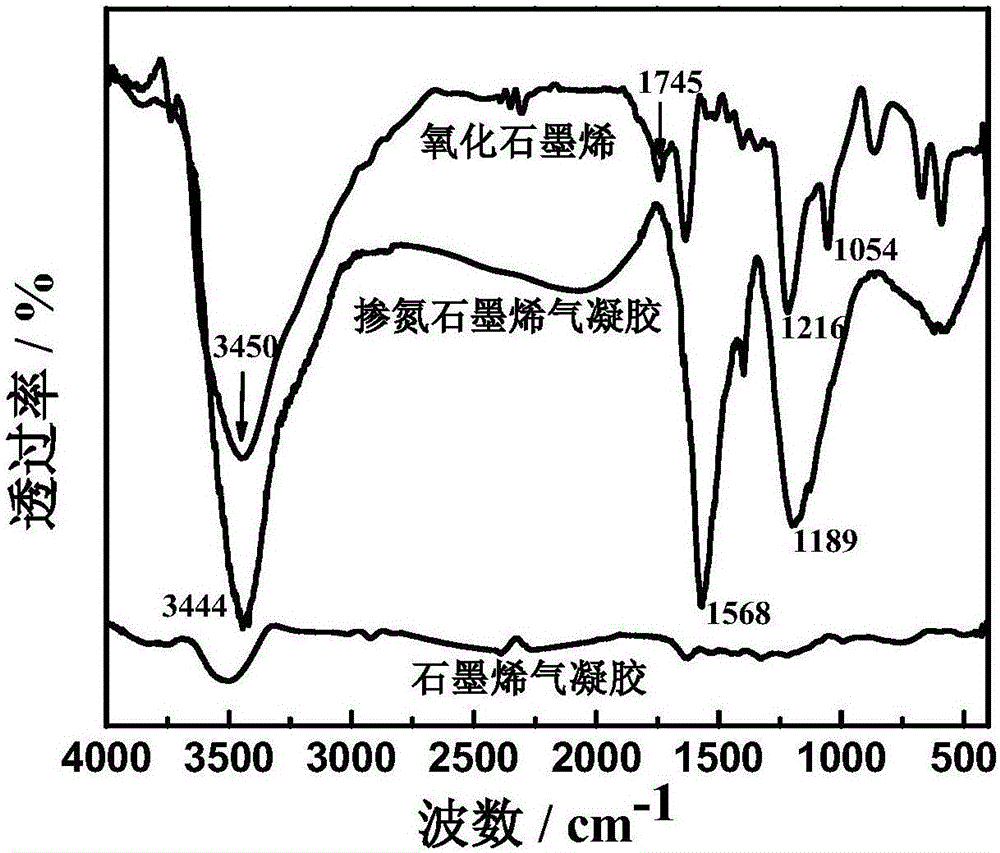

[0024] (1) 0.2 g of graphene oxide (GO) was ultrasonically dispersed in 100 ml of distilled water, and then 6 g of urea was added, and mechanically stirred for 15 min. The mixture was poured into a hydrothermal reactor and heated to 180°C for 12 hours. The resulting product was immersed in distilled water for 3 to 4 days, and finally the sample was freeze-dried at -50°C for 24 hours to obtain nitrogen-doped graphene airgel.

[0025] (2) Add 90 mg of the nitrogen-doped graphene airgel material prepared in step (1) into 2 mL of 4 wt % polyvinyl alcohol solution, and ultrasonically disperse the composite material in the solution evenly. Take 0.16mL of the above dispersion liquid and apply it evenly on a 20mm×5mm hard paper sheet (thickness 400μm), and freeze-dry it at -50°C for 4h to make a nitrogen-doped graphene airgel paper electrode.

[0026] The prepared nitrogen-dope...

Embodiment 2

[0028] The preparation process of the nitrogen-doped graphene airgel paper electrode is the same as that of Example 1.

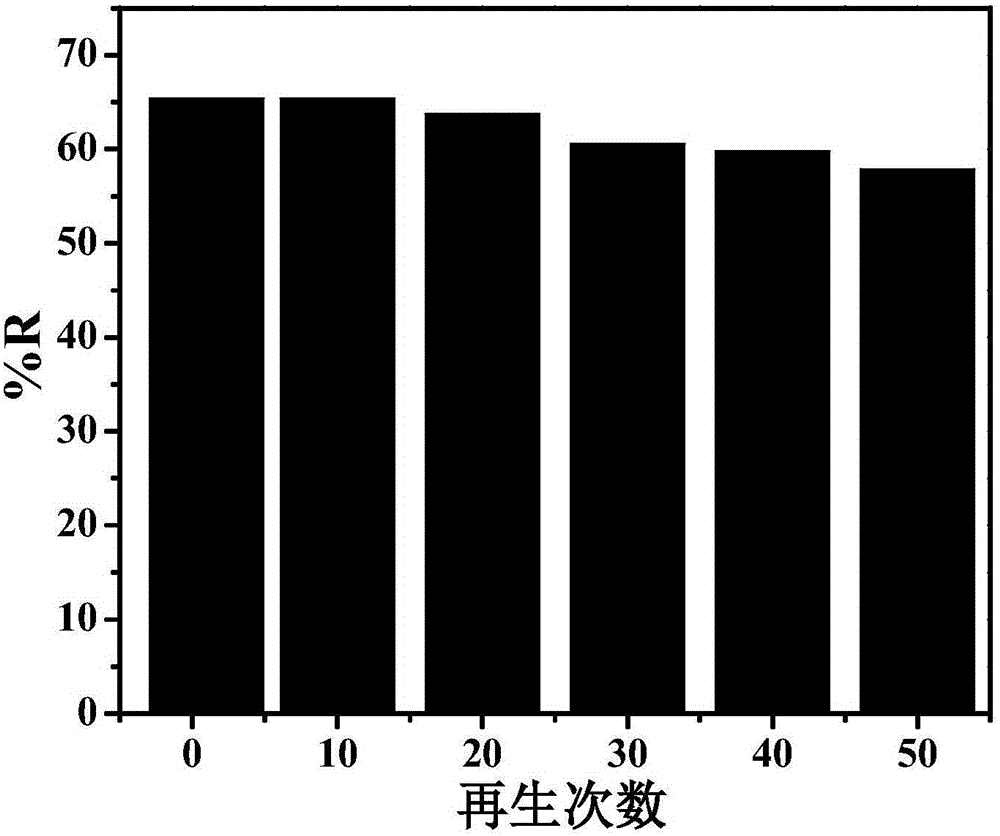

[0029] Cyclic electrosorption experiments were performed on nitrogen-doped graphene airgel paper electrodes. Place the nitrogen-doped graphene airgel paper electrode in 80mL of As with a concentration of 0.25mmol / L 3+ In the solution, apply a potential of -0.3V, and record the conductivity of the solution, record the conductivity of the solution again after 2 minutes, and calculate the removal rate. Then the potential was removed to allow it to desorb, and the cycle was repeated several times. Experimental results such as image 3 shown. The first adsorption of As 3+ The removal rate was 65.4%. After 30 cycles of use, the electrode paired As 3+ The removal rate was 64.4%, and the removal rate only decreased by 1%, but when the cycle experiment was continued, the removal rate began to show a downward trend.

Embodiment 3

[0031] The preparation process of the nitrogen-doped graphene airgel paper electrode is the same as that of Example 1.

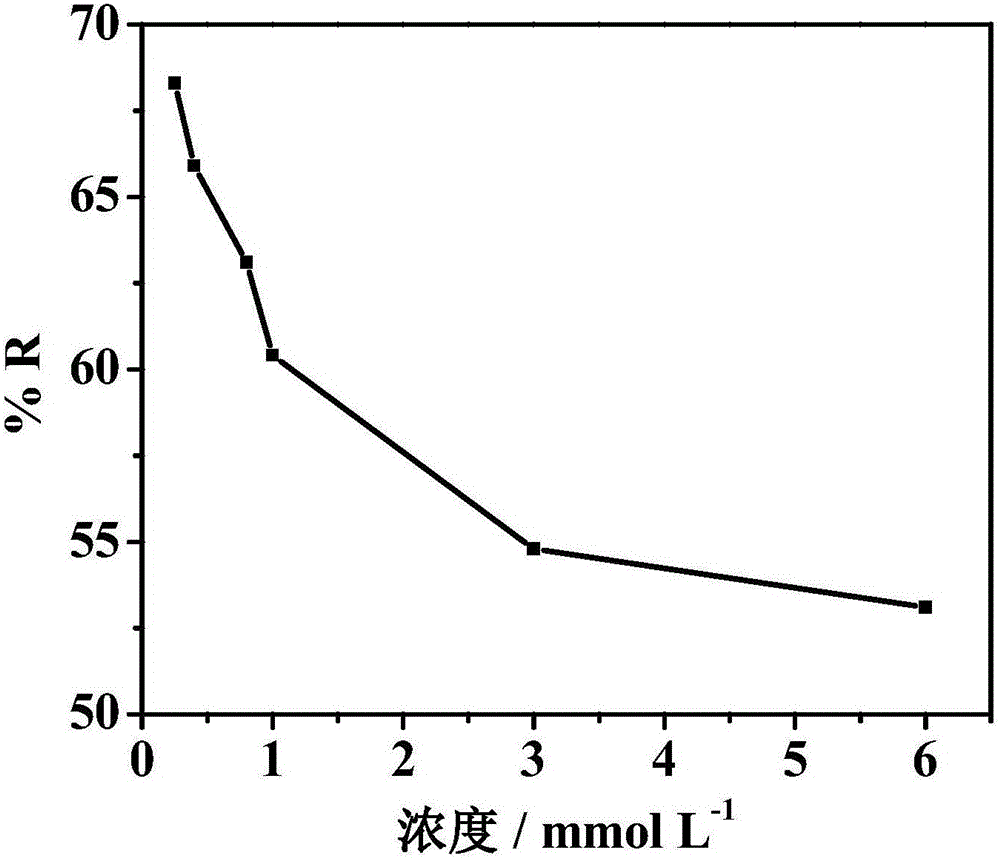

[0032] Prepared nitrogen-doped graphene airgel paper electrode for 3 mM As 3+ For the electrochemical treatment of the solution, the applied voltage was -0.3V, and the treatment time was 2min. Such as Figure 4 As shown, nitrogen-doped graphene airgel paper electrode pair As 3+ The removal rate is 52%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com