Chassis type bearing mechanism

A technology of bearing mechanism and chassis, applied in the direction of lifting device, etc., to achieve the effect of small welding deformation, lower requirements and simple welding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

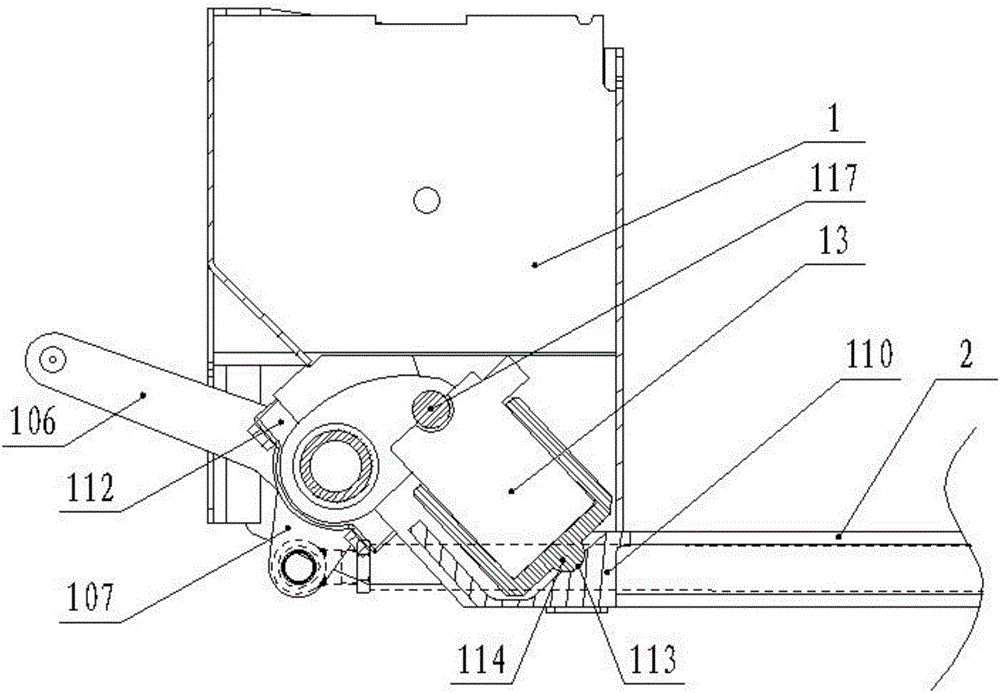

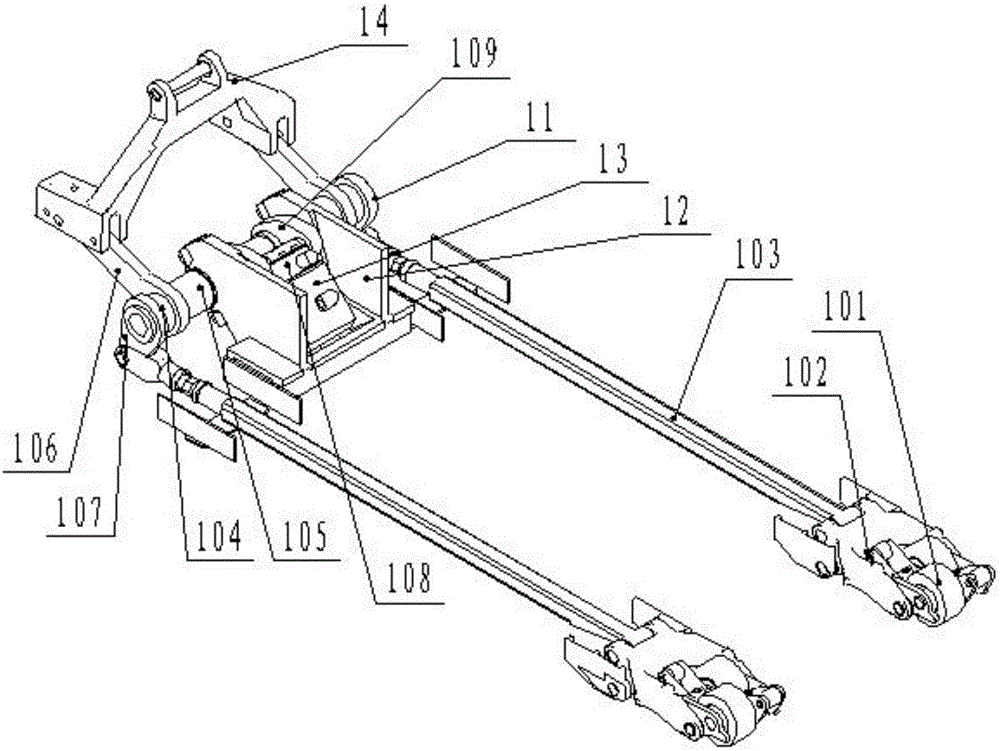

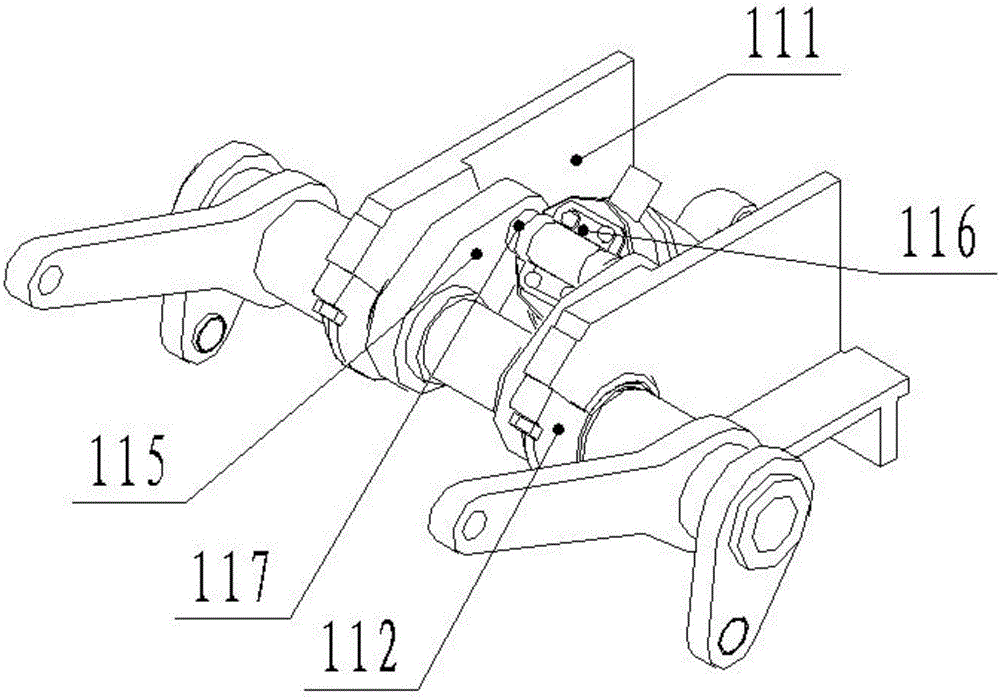

[0021] Chassis bearing mechanism, such as Figure 1-Figure 3 As shown, it includes a vehicle frame 1 and a link mechanism 11 for realizing the lifting of the vehicle frame 1, and also includes a mounting seat 12 fixed on the bottom of the vehicle frame 1. An oil cylinder 13 is installed on the mounting seat 12, and the plunger rod of the oil cylinder 13 108 is connected with the link mechanism 11 , and the link mechanism 11 is connected on the mounting base 12 .

[0022] Wherein, the link mechanism 11 includes a load wheel frame 102 with a load wheel 101, a long link 103 hinged with the load wheel frame 102 and a lower link 104 hinged with the long link 103; the lower link 104 includes a link shaft 105 , the long arm 106 hinged with the bearing bridge 14 , the short arm 107 hinged with the long connecting rod 103 , and the driving arm 109 connected with the plunger rod 108 of the oil cylinder 13 are fixed on the connecting rod shaft 105 . The driving arm 109 includes two side...

Embodiment 2

[0028] The same as the first embodiment, the difference is that the bottom plate 110 and the two side plates 111 are integrally cast, so that the overall strength of the mounting seat 12 is higher, and then the load-bearing strength of the entire load-bearing structure is improved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com