Dust collection type woven fabric printing device for spinning

A printing and dust collection technology, applied in printing, printing machines, rotary printing machines, etc., can solve the problems of inability to mass-produce products, imperfect processes, secondary pollution of weaving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Specific embodiments of the present invention will be further described in detail below.

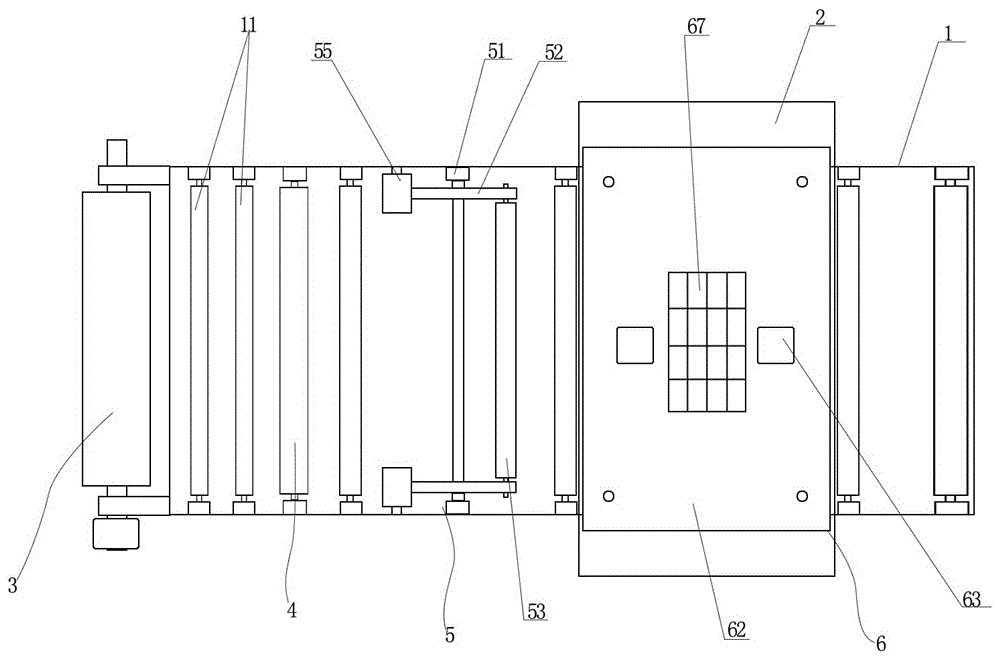

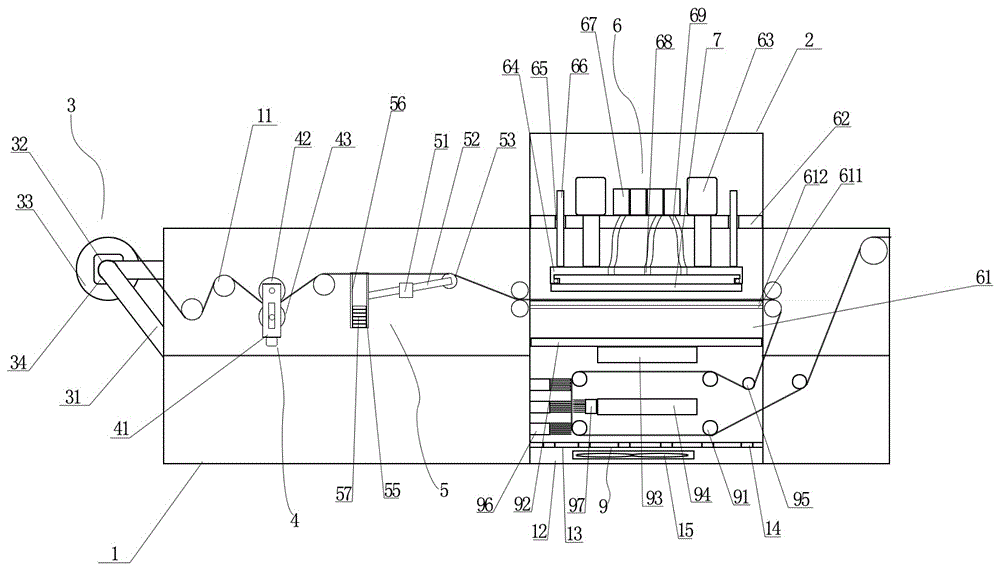

[0020] Such as Figure 1 to Figure 3 As shown, a dust-collecting textile weaving printing device of the present invention includes a first frame 1 and a second frame 2 arranged crosswise, the second frame 2 is higher than the second frame 2, and its characteristic In that: the first frame 1 includes a feeding device for conveying the woven cloth, and the second frame 2 includes a printing mechanism 6 for woven cloth printing;

[0021] The feeding device includes a loom stocker 3, a loom tractor 4 and a tension mechanism 5, the loom stocker 3 is arranged on the outer side of the first frame 1, and the loom tractor 4 is provided with two In the first frame 1 and divided into both sides of the second frame 2, the tensioning mechanism 5 is arranged in the first frame 1 between the weaving tractor 4 and the second frame 2;

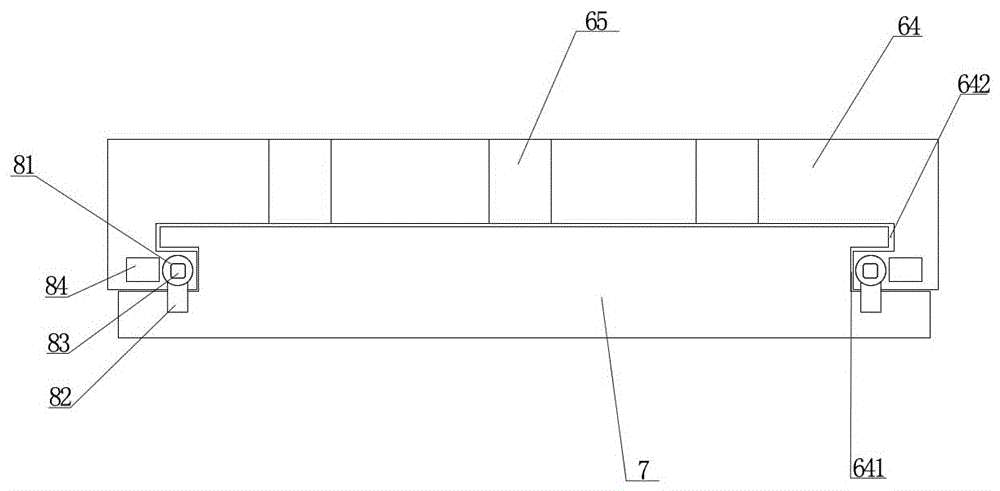

[0022] The printing mechanism 6 includes a receiving seat 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com