A kind of non-milk heat-sealing film and preparation method thereof

A technology of heat sealing and heat sealing layer, which is applied in the direction of chemical instruments and methods, flexible coverings, coatings, etc., can solve the problems of poor heat sealing performance and non-stick milk effect, and achieve enhanced heat sealing effect and sealing effect , tightly combined, to avoid the effect of milk sticking to the cover film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

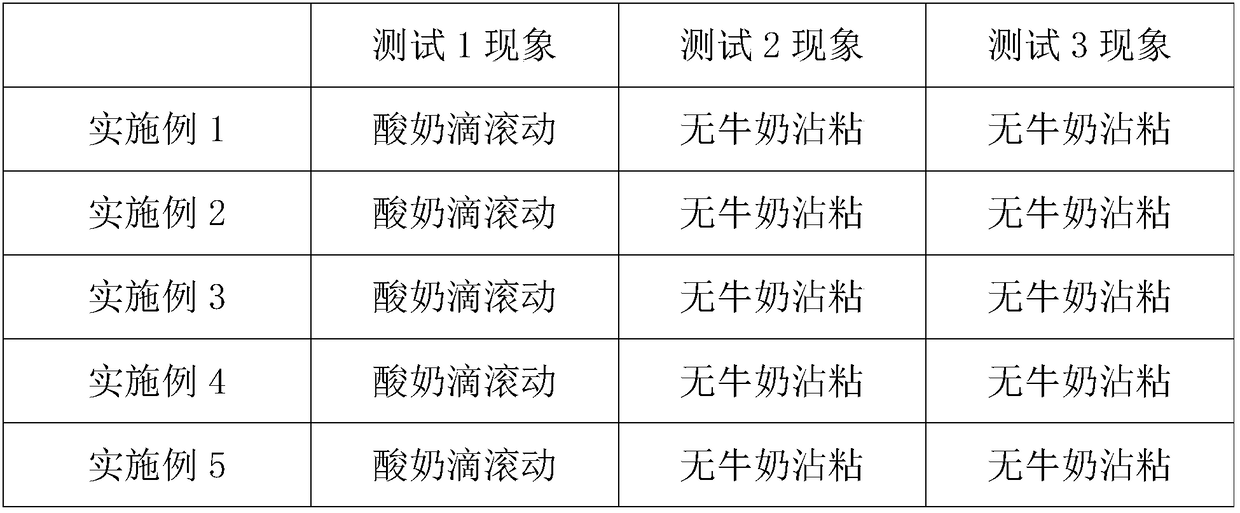

Embodiment 1

[0041]This embodiment provides a milk-free heat-sealing film and a preparation method thereof. The milk-free heat-sealing film consists of a varnish layer, an ink layer, a paper layer, a VM-PET layer, a heat-sealing layer and a hydrophobic coating from the outside to the inside;

[0042] Among them, the paper weight is 50g / m 2 ; The thickness of the VM-PET layer is 12 μm; the heat-sealing layer is an acrylic resin layer with a thickness of 8 μm, a surface roughness of 5 μm, and an acrylic resin molecular weight of 75 000 to 120 000, with a weight of 5 g / m 2 ; The hydrophobic coating is a nano-silicon coating with a thickness of 5 μm and a nano-silicon particle size of 1-5 nm.

[0043] The preparation method of the milk-free heat-sealing film provided in this embodiment comprises the following steps:

[0044] S1. Use a gravure printing machine to print on the paper layer to form an ink layer. The printing speed is controlled at 150m / min, and the drying temperature is 60°C to ...

Embodiment 2

[0051] This embodiment provides a milk-free heat-sealing film and a preparation method thereof. The milk-free heat-sealing film consists of a varnish layer, an ink layer, a paper layer, a VM-PET layer, a heat-sealing layer and a hydrophobic coating from the outside to the inside;

[0052] Among them, the paper weight is 40g / m 2 ; The thickness of the VM-PET layer is 12 μm; the heat-sealing layer is an acrylic resin layer with a thickness of 2 μm, a surface roughness of 1 μm, and an acrylic resin molecular weight of 75 000 to 120 000, with a weight of 5 g / m 2 ; The hydrophobic coating is a nano-silicon coating with a thickness of 1 μm and a nano-silicon particle size of 5-10 nm.

[0053] The preparation method of the milk-free heat-sealing film provided in this embodiment comprises the following steps:

[0054] S1. Use a gravure printing machine to print on the paper layer to form an ink layer. The printing speed is controlled at 100m / min, and the drying temperature is 80°C t...

Embodiment 3

[0061] This embodiment provides a milk-free heat-sealing film and a preparation method thereof. The milk-free heat-sealing film consists of a varnish layer, an ink layer, a paper layer, a VM-PET layer, a heat-sealing layer and a hydrophobic coating from the outside to the inside;

[0062] Among them, the paper weight is 80g / m 2 ; The thickness of the VM-PET layer is 12 μm; the heat-sealing layer is an acrylic resin layer with a thickness of 10 μm, a surface roughness of 6 μm, and an acrylic resin molecular weight of 75 000 to 120 000, with a weight of 5 g / m 2 The hydrophobic coating is a nano-silicon coating with a thickness of 10 μm and a nano-silicon particle size of 10-15nm.

[0063] The preparation method of the milk-free heat-sealing film provided in this embodiment comprises the following steps:

[0064] S1. Use a gravure printing machine to print on the paper layer to form an ink layer. The printing speed is controlled to 220m / min, and the drying temperature is 40°C t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com