Elastic conductive composite fabric and preparation method thereof

A composite fabric, elastic and conductive technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, applications, etc., can solve the problems of increasing fabric thickness and hardness, increasing the difficulty of weaving process, and poor washing resistance, so as to improve flexibility Improvement of electrical safety and durability, good electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1: Ultra-thin elastic conductive composite fabric

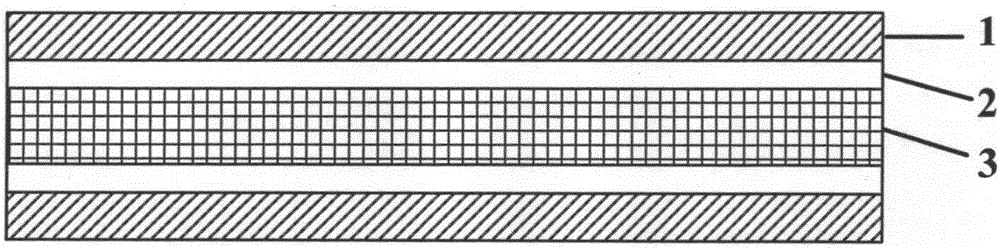

[0028] like figure 1 As shown, an elastic conductive composite fabric includes a spandex elastic fabric 1 , an adhesive layer 2 , a flexible nano-conductive film 3 , an adhesive layer 2 and a spandex elastic fabric 1 arranged in sequence from top to bottom.

[0029] Its preparation method is:

[0030] 1. Materials:

[0031] (1) The two spandex elastic fabrics 1 are made of ultra-fine and ultra-thin Lycra cloth, which is a blended fabric of nylon and spandex, weight: 110g / m 2 , Yarn count: 20D, composition and content: Nylon: 80%, Spandex: 20%, size is 40×40cm 2 .

[0032] (2) The selected size is 60×40cm 2 The carbon nanotube film (Suzhou Institute of Nanotechnology and Nano-Bionics, Chinese Academy of Sciences) is used as a flexible nano-conducting film 3, which is made of multi-wall carbon nanotubes. The diameter of the carbon nanotubes is about 20nm, the film thickness is 20um, and the porosity is 75%. ...

Embodiment 2

[0040] Example 2: Elastic conductive composite fabric of polyester

[0041] like figure 1 As shown, an elastic conductive composite fabric includes a spandex elastic fabric 1 , an adhesive layer 2 , a flexible nano-conductive film 3 , an adhesive layer 2 and a spandex elastic fabric 1 arranged in sequence from top to bottom.

[0042] Its preparation method is:

[0043] 1. Materials:

[0044] (1) The two spandex elastic fabrics 1 are made of 100D polyester four-sided elastic fabric, which is a blended fabric of polyester and spandex, weight: 125g / m 2 , composition and content: polyester: 90%, spandex: 10%, size is 40×40cm 2 .

[0045] (2) The selected size is 60×40cm 2 The carbon nanotube film (Suzhou Institute of Nanotechnology and Nano-Bionics, Chinese Academy of Sciences) is used as a flexible nano-conducting film 3, which is made of multi-wall carbon nanotubes. The diameter of the carbon nanotubes is about 20nm, the film thickness is 20um, and the porosity is 75%. %, ...

Embodiment 3

[0052] Example 3: Wear-resistant elastic conductive composite fabric

[0053] like figure 1 As shown, an elastic conductive composite fabric includes a spandex elastic fabric 1 , an adhesive layer 2 , a flexible nano-conductive film 3 , an adhesive layer 2 and a spandex elastic fabric 1 arranged in sequence from top to bottom.

[0054] Its preparation method is:

[0055] 1. Materials:

[0056] (1) The two spandex elastic fabrics 1 are made of high-density nylon four-sided elastic fabric, which is a blended fabric of nylon and spandex, weight: 168g / m 2 , Composition and content: Nylon: 84%, Spandex: 16%, size is 40×40cm 2 .

[0057] (2) The selected size is 60×40cm 2 The carbon nanotube film (Suzhou Institute of Nanotechnology and Nano-Bionics, Chinese Academy of Sciences) is used as a flexible nano-conducting film 3, which is made of multi-wall carbon nanotubes. The diameter of the carbon nanotubes is about 20nm, the film thickness is 20um, and the porosity is 75%. %, th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com