Polystyrene stirring tank with automatic spraying device

An automatic spraying and polystyrene technology, applied in the field of polystyrene stirring tanks, can solve the problems of increasing spraying and stirring time, unfavorable material mixing and foaming, and poor control of humidity, etc. Light weight and prevent material from flying

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

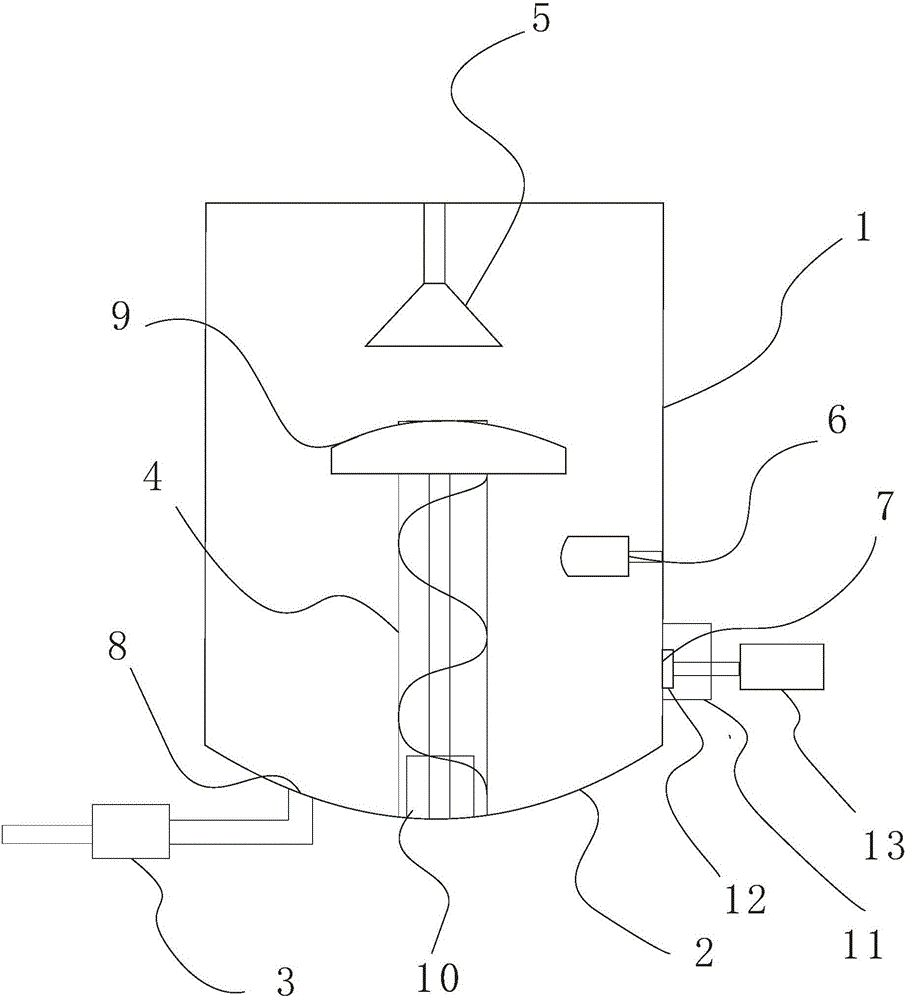

[0010] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0011] As shown in the figure, a polystyrene mixing tank with an automatic spraying device includes a tank body 1 and an automatic spraying device provided with an inlet 8 and an outlet 7, and the inlet 8 is provided with At the bottom of the tank body 1, the discharge port 7 is arranged on the side of the tank body, the bottom surface of the tank body 2 is a slope structure with high surroundings and low middle, and the inner middle of the tank body 1 is provided with a lifting auger 4, so that The bottom of the lifting auger 4 is provided with a lifting auger feeding port 10, the lifting auger feeding port 10 is located at the lowest point of the tank bottom 2, and the top of the lifting auger 4 is provided with an arc-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com