Direction-adjustable self-feeding type electric scissors

An electric scissors, self-advancing technology, applied in the cutting of textile materials, textiles and papermaking, metal processing and other directions, can solve the problems of difficulty in determining the cutting speed, cannot be changed, inconvenient, etc., to achieve uniform cutting speed and good cutting effect. , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

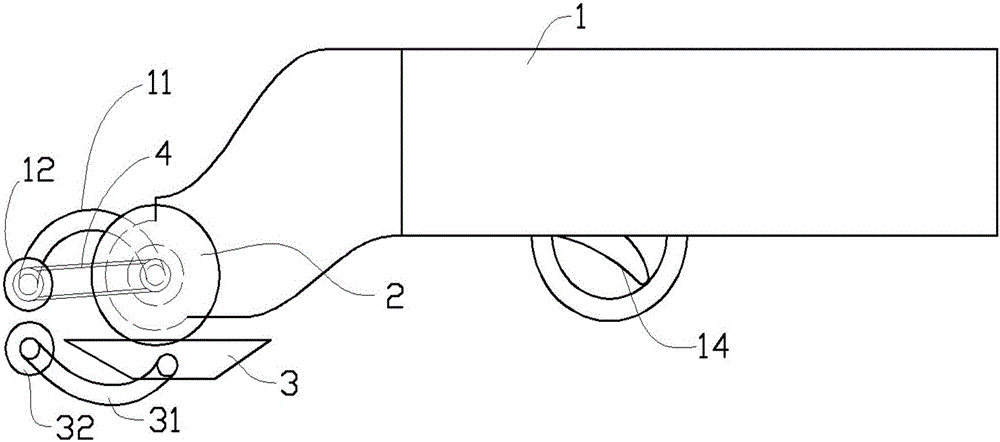

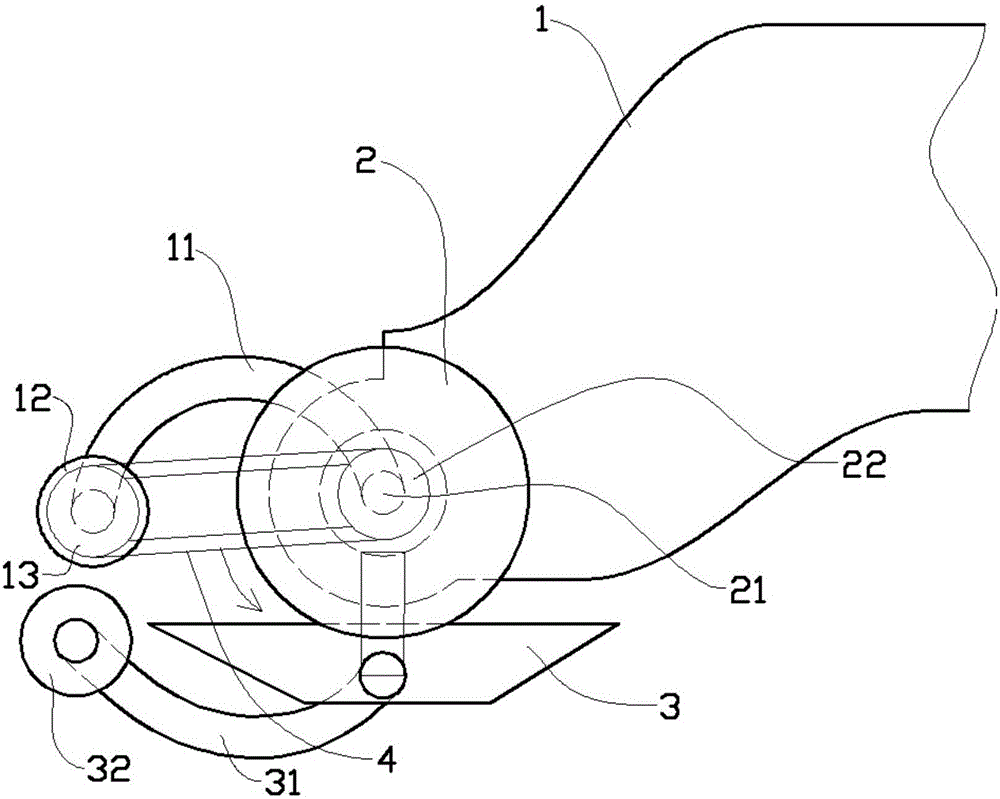

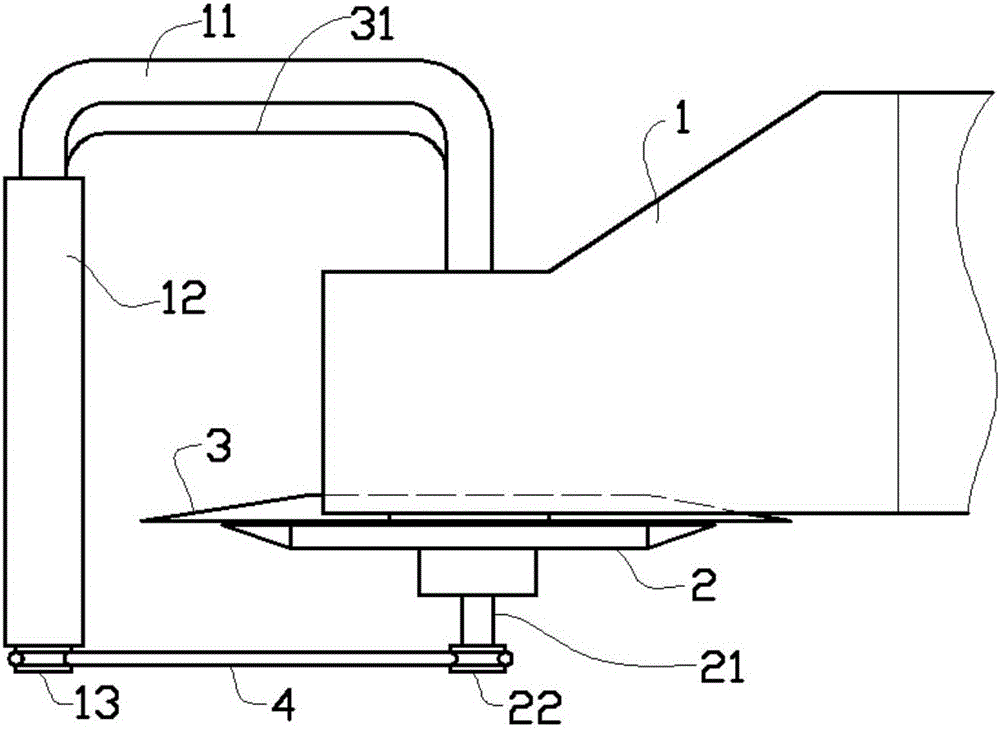

[0019] like figure 1 , figure 2 and image 3 As shown in the embodiment, the direction-adjustable self-feeding electric scissors include a housing 1, the housing 1 is equipped with a transmission mechanism, and the front end of the housing 1 is equipped with a circular main body that can rotate from its axis. Blade 2, the below of described main blade 2 is equipped with the sub-blade 3 of linear cutting edge, and the outer ring of described main blade 2 is all designed as cutting edge, and the edge tangent direction of described main blade 2 and the edge of sub-blade 3 The mouth forms an acute angle, the installation shaft 21 of the main blade 2 is in the horizontal direction, one end of the installation shaft 21 of the main blade 2 extends out of the housing horizontally, and the extension end of the installation shaft 21 is equipped with a driving pulley 22, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com