A construction and handling industrial robot based on redundant four degrees of freedom

An industrial robot, construction technology, applied in conveyors, manipulators, manufacturing tools, etc., can solve the problems of low handling efficiency, many hidden dangers of dangerous accidents, material slippage, etc., to achieve easy walking, good movement flexibility, and movement speed quick effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

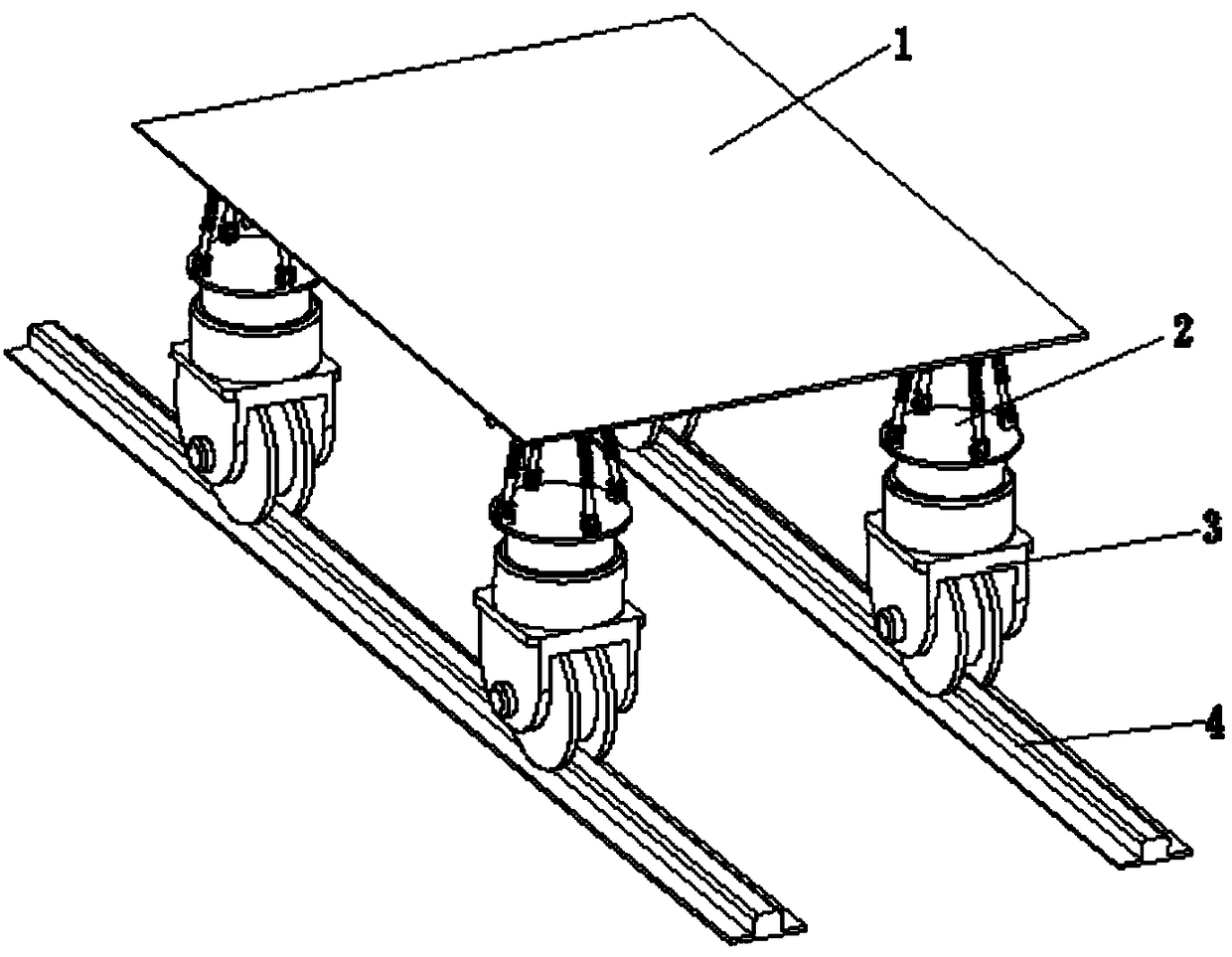

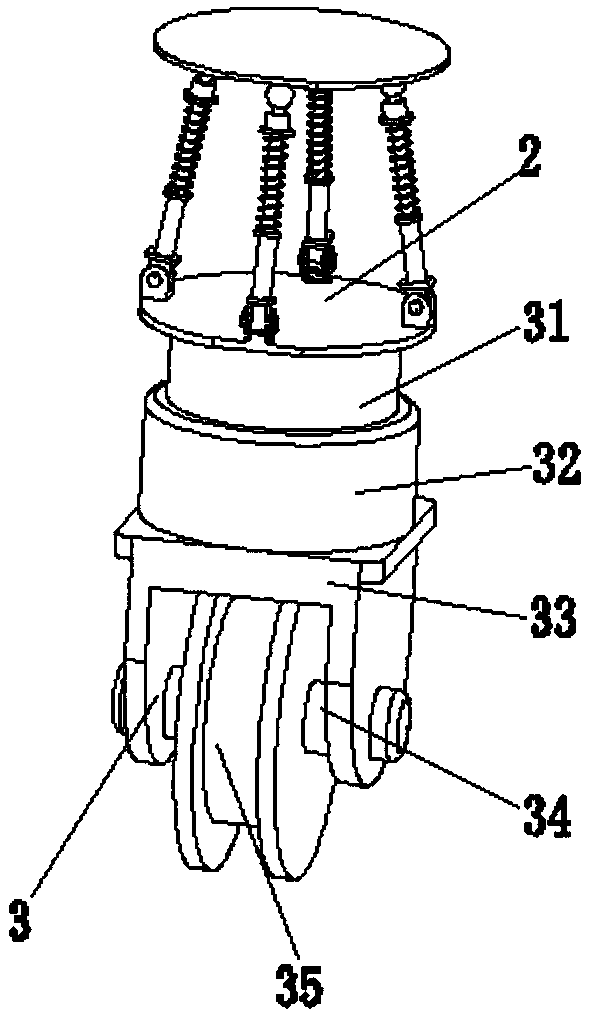

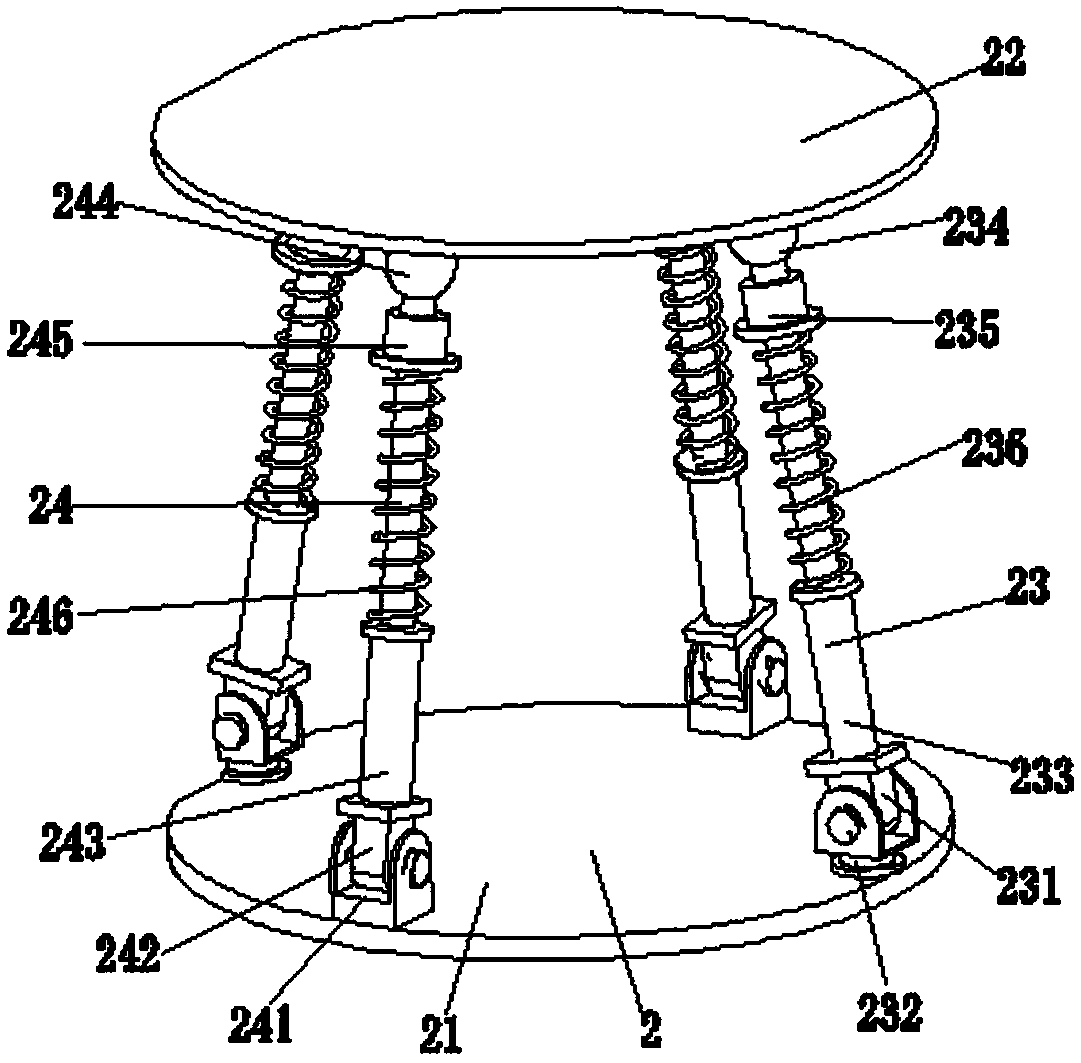

[0016] Such as figure 1 , figure 2 and image 3 As shown, a building construction handling industrial robot based on redundant four-degree-of-freedom, including a handling platform 1, a redundant four-degree-of-freedom shock absorber 2, a walking device 3 and a track 4, and a redundant four-degree-of-freedom shock absorber 2 and the number of walking devices 3 are four; the carrying platform 1 is a rectangular flat structure, and the material of the carrying platform 1 is 45 steel materials, and the redundant four-degree-of-freedom shock absorbers 2 are respectively located at the four corners of the carrying platform 1, And the redundant four-degree-of-freedom shock absorber 2 is connected to the bottom surface of the transport platform 1 th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com