Modified capsule polisher capable of sorting capsules

A polishing machine, an improved technology, applied to surface polishing machine tools, grinding/polishing equipment, solid separation, etc., can solve problems such as wasting labor, slow sorting speed, and affecting production efficiency, and achieve convenient adjustment, labor saving, and improved Efficiency and manpower saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

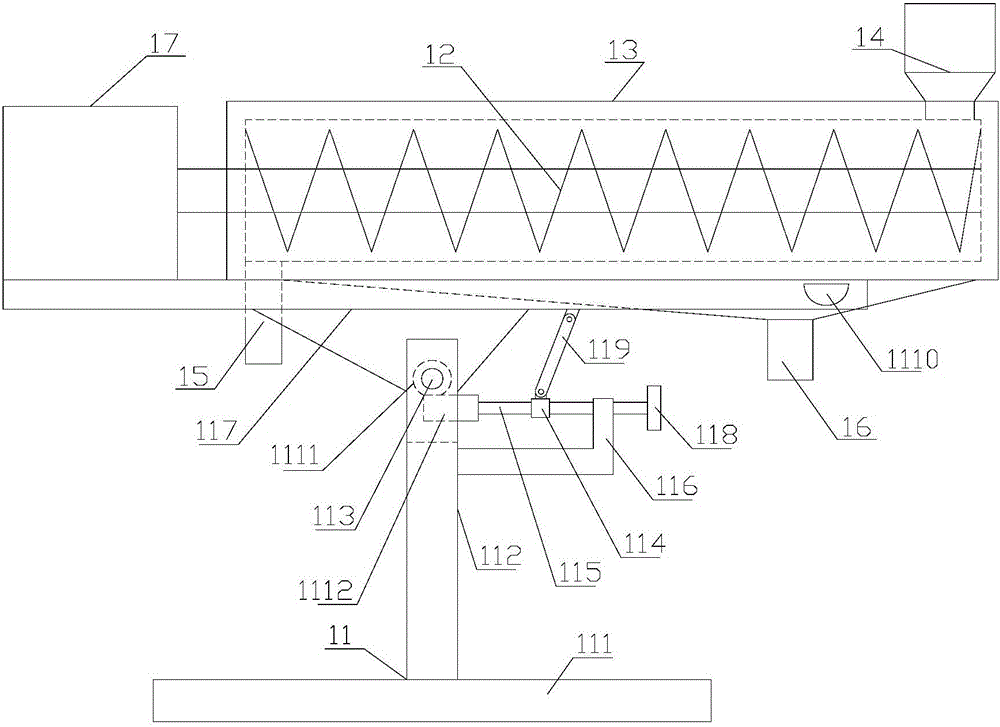

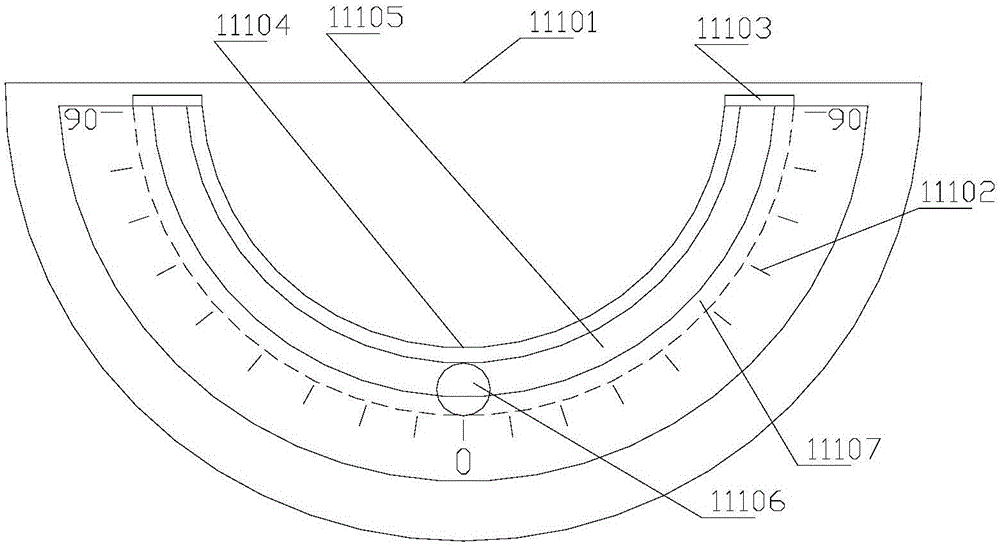

[0021] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6, an improved capsule polishing machine capable of sorting capsules according to the present invention, comprising a polishing mechanism 1 and a sorting device 2, the polishing mechanism 1 comprising a frame 11, a polishing brush 12, a polishing cylinder 13, a feed inlet 14, an outlet Material opening 15, powder suction port 16 and motor 17, described frame 11 is provided with polishing cylinder 13 and motor 17, and the rear end top of described polishing cylinder 13 is provided with feeding inlet 14, and the front end of described polishing cylinder 13 The bottom is provided with a discharge port 15, the bottom of the polishing cylinder 13 is provided with a powder suction port 16, the polishing cylinder 13 is provided with a polishing brush 12, the rotating shaft of the motor 17 is connected with the shaft transmission of the polishing brush 12, The frame 11 includes a first base 111, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com