Compressing device for counterweight filler of elevator

A technology of pressing device and counterweight, which is used in transportation and packaging, elevators, lifting equipment in mines, etc., can solve the problems of high labor intensity, complex structure, easy failure, etc. Easy to adjust and labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

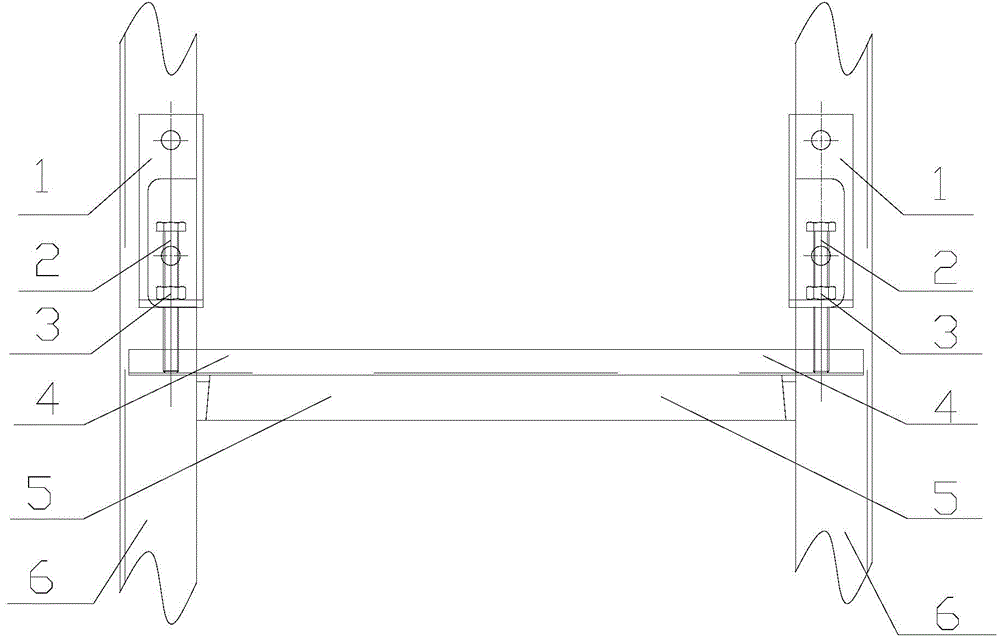

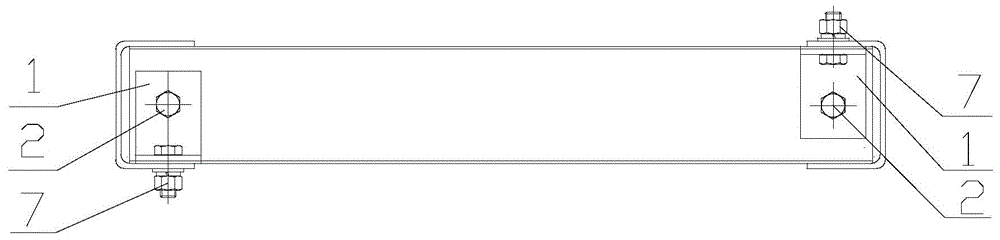

[0019] see figure 1 and 2 , an elevator counterweight pressing device, which includes a frame with two left and right vertical beams 6 and a pressing plate 4 for pressing the counterweight 5, and the left and right vertical beams 6 all have front side walls and rear A fixing part 1 is installed on the side wall, the left and right vertical beams 6, the fixing part 1 is welded with a nut 3, the nut 3 is threaded with a compression bolt 2, the compression bolt 2 is vertically arranged, and its lower end is against the pressure plate 4 Apply compressive force. In this implementation, the fixing part 1 adopts an L-shaped baffle, and the left and right fixing parts 1 are set one after the other, and are fastened to the beam 6 by the bolt assembly 7 . The arrangement of the two fixing parts 1 one behind the other can make the internal stress distribution of the counterweight frame more uniform, and avoid the reaction force of the pressing force of the pressing bolts 2 on both side...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com