A device and method for drilling a hole using a laser beam

A laser beam and laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve problems such as complex devices, difficult operation, and precision requirements of the laser coaxial movement platform, to achieve improved taper and easy operation line effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] For ease of understanding, the present invention will be further described below in conjunction with the accompanying drawings.

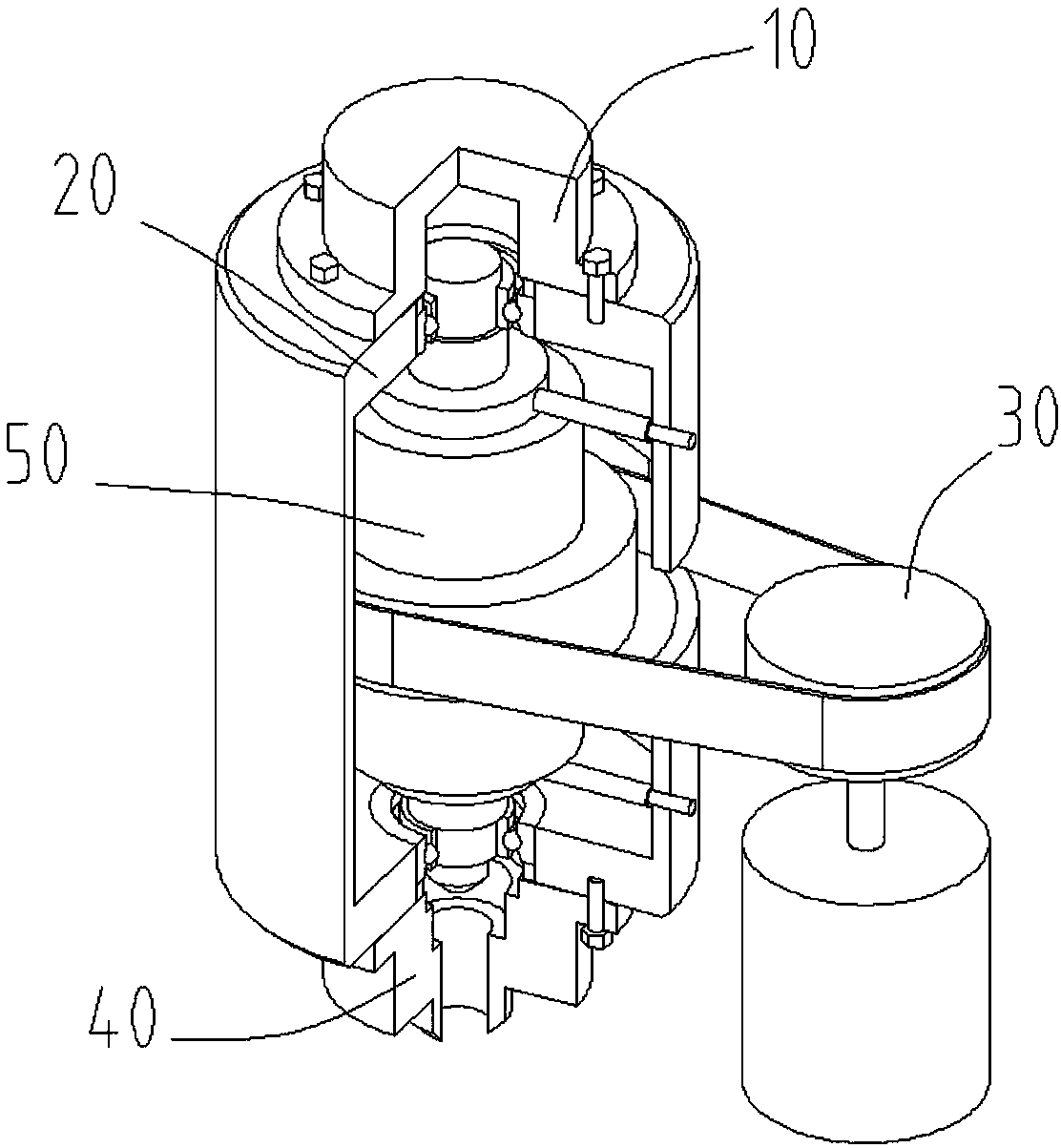

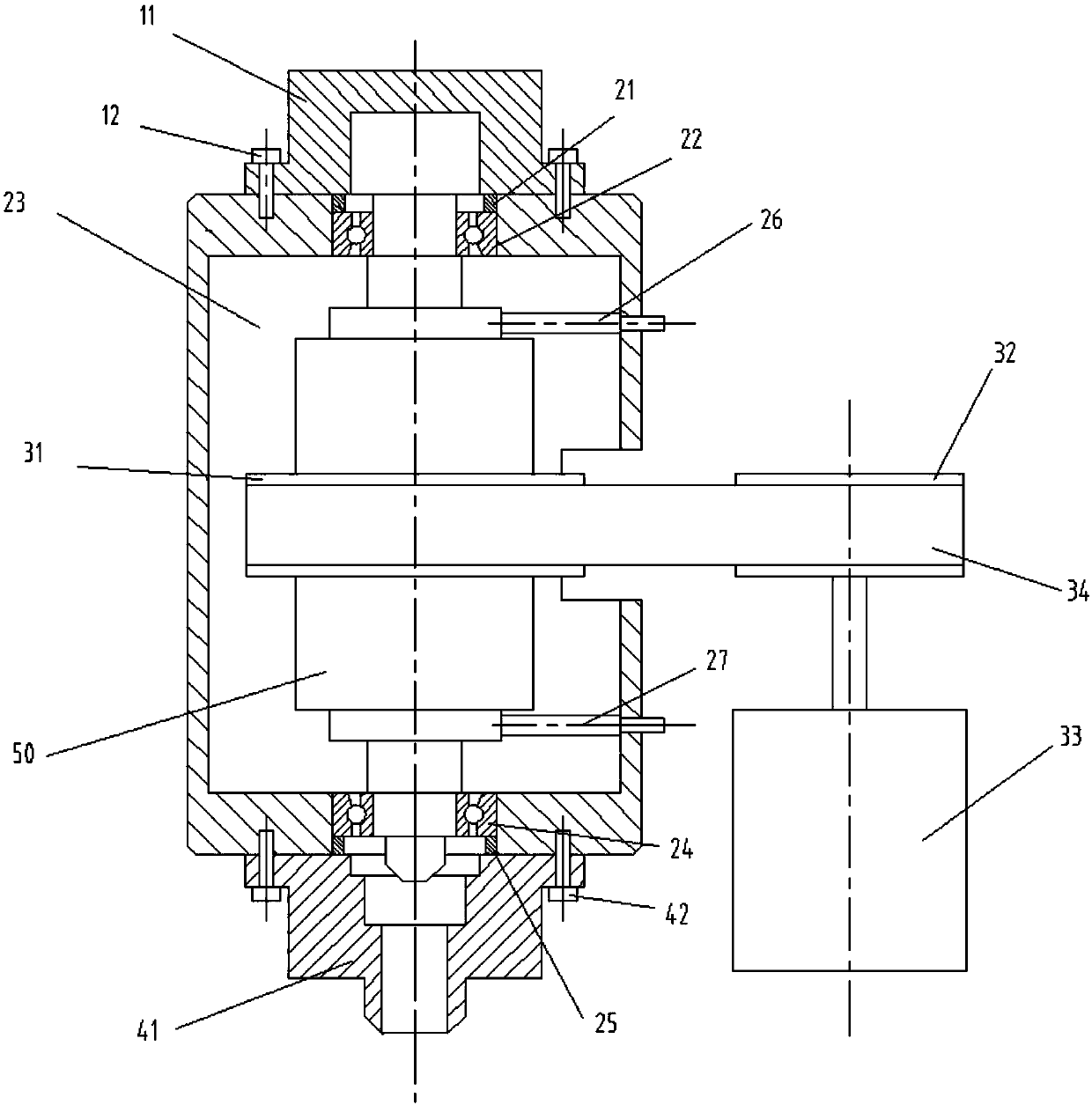

[0040] see figure 1 and figure 2 , figure 1 It is a schematic diagram of a device for drilling holes with a laser beam provided by an embodiment of the present invention, figure 2 Yes figure 1 sectional view.

[0041] A device for drilling holes with a laser beam provided in an embodiment of the present invention includes a container 20 , a laser output shaper 50 and a drive system 30 .

[0042] Wherein, the container 20 has an inner cavity 23, and the lower end of the container 20 is provided with a light outlet (not marked in the figure);

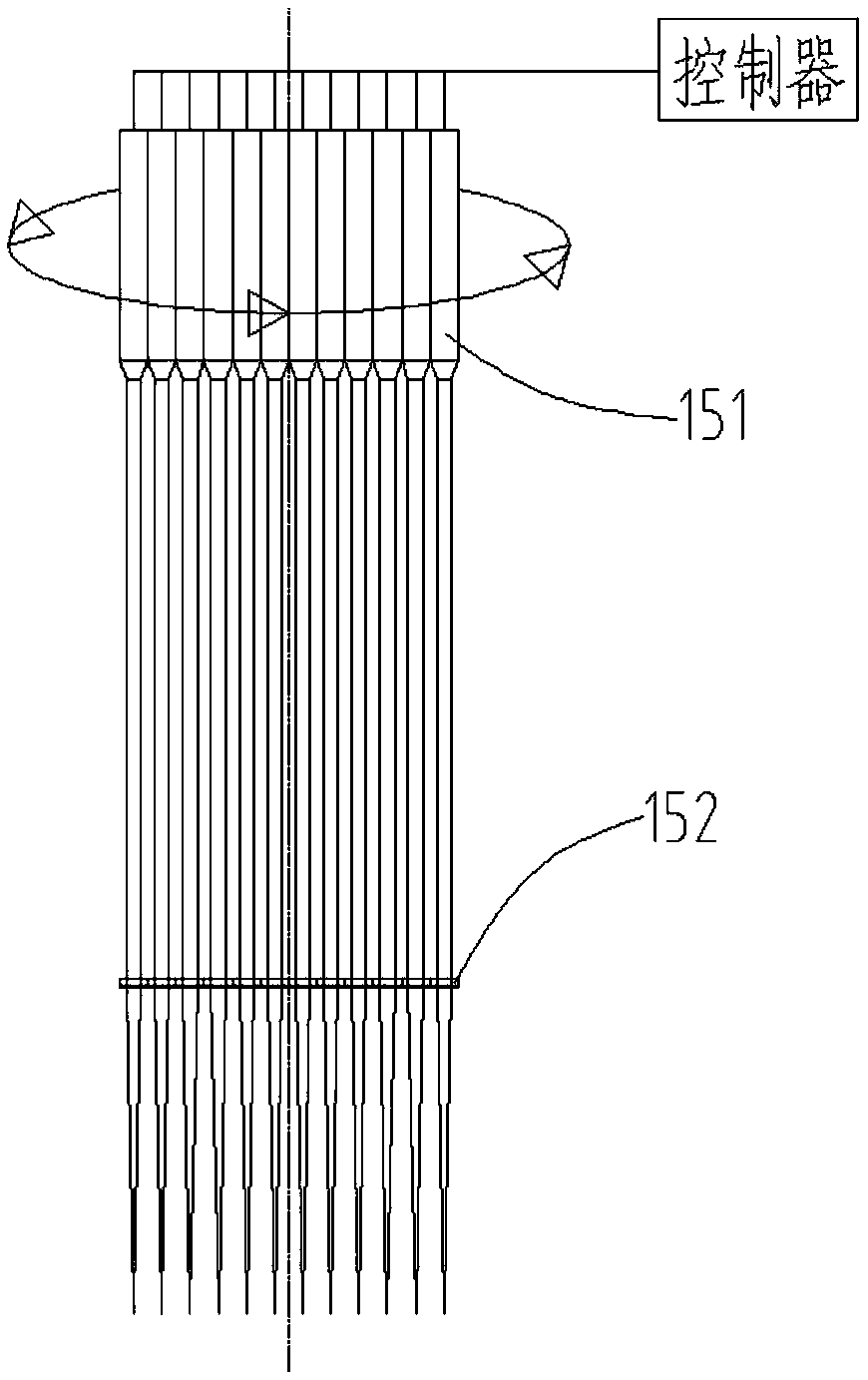

[0043] The laser output shaper 50 is located in the container 20 and is rotatably connected with the container 20. The laser output shaper 50 includes a laser array and a convex lens array. An even number of lasers, the lasers are used to emit parallel beams vertically downward, the convex lens a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com