Friction stir welding tool with multi-parameter feedback

A friction stir welding, multi-parameter technology, applied in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve problems such as poor effect, uncontrollable and undetectable weld seam defects, weld seam tail, etc., and achieve the goal of improving welding quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

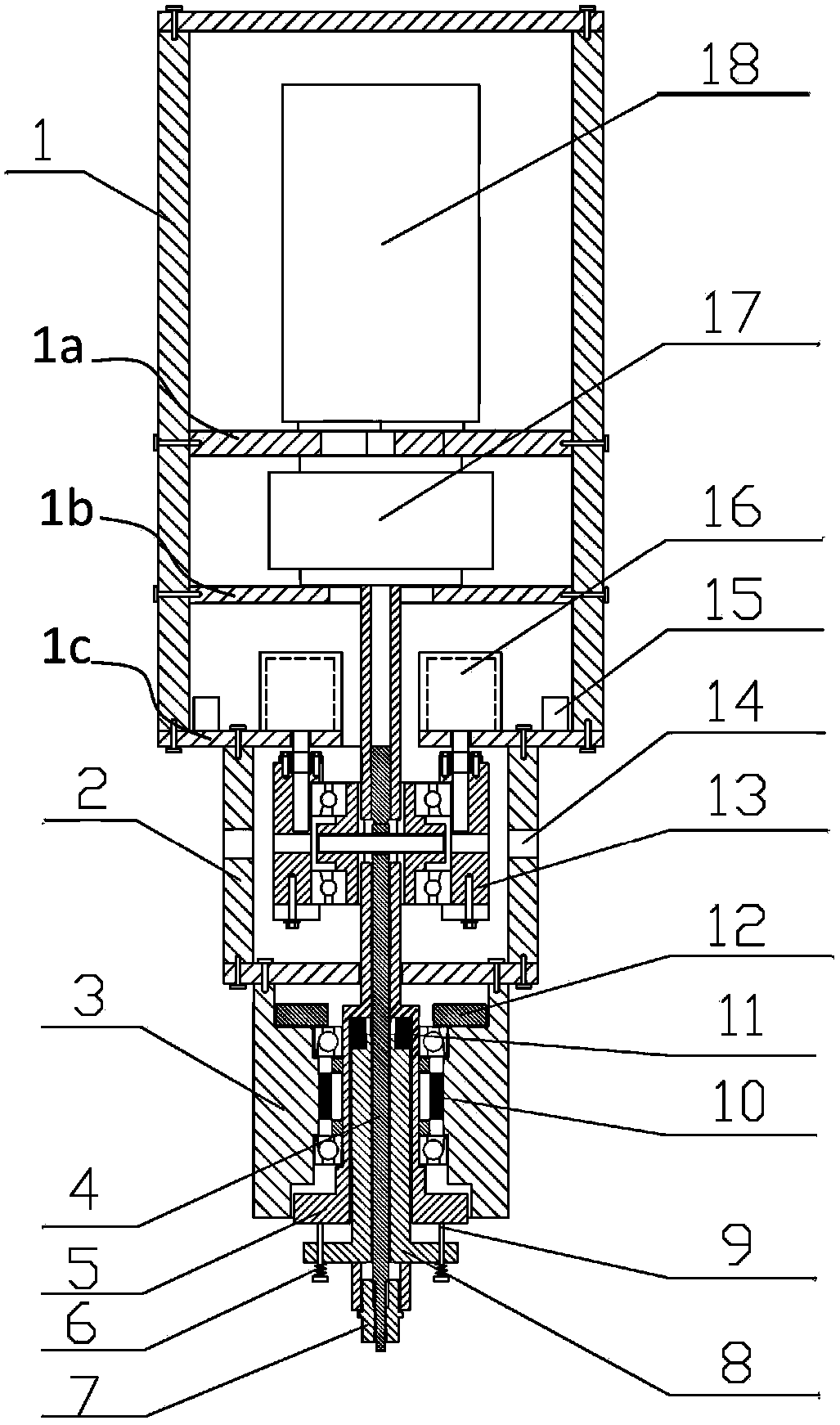

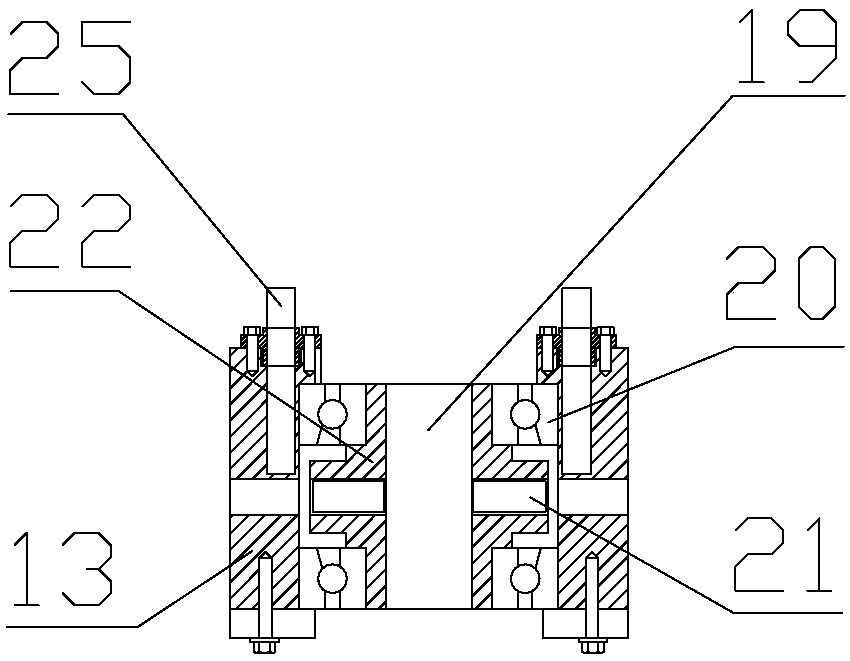

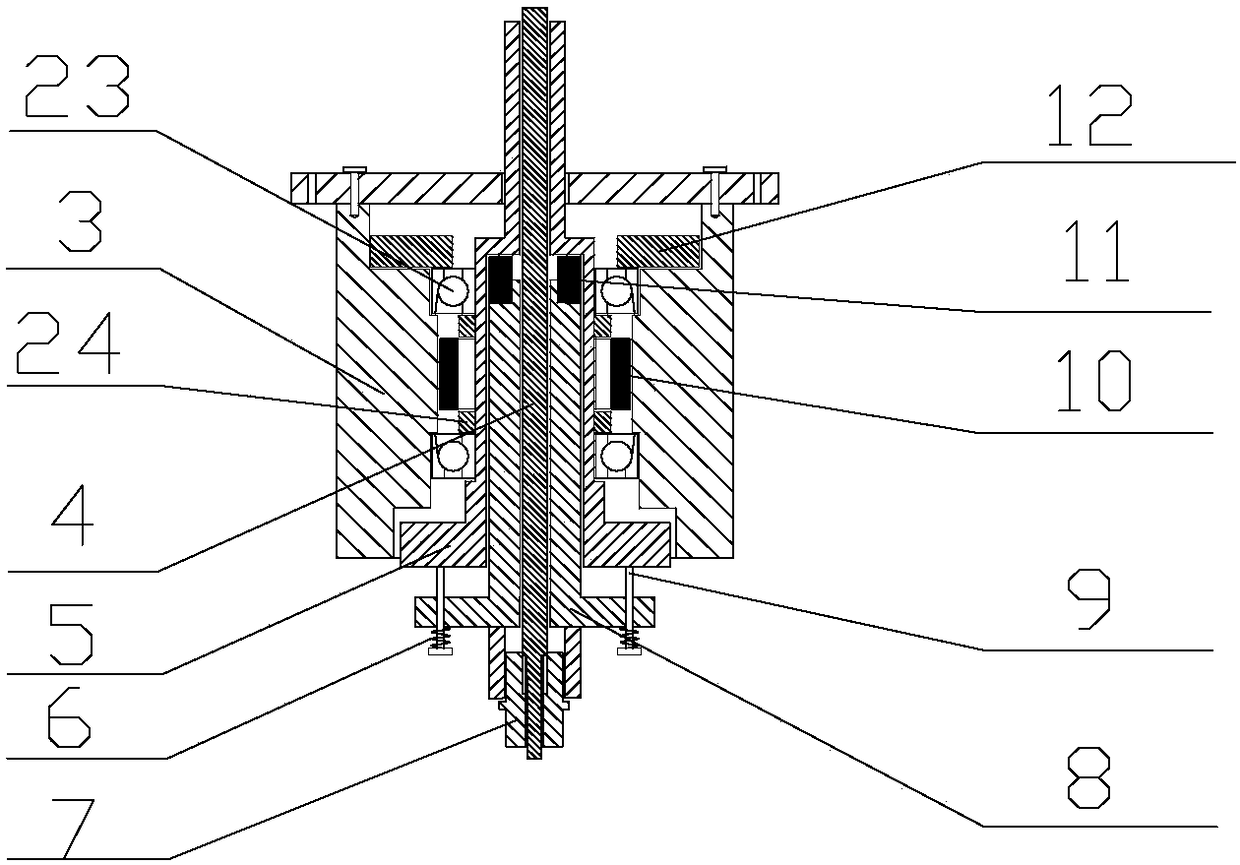

[0014] The applicant conducted research and analysis on existing patents and papers. For example, prior art 1 proposes a friction stir welding device, but does not provide a specific method for how to measure the depression depth of the stirring head and the inclination angle of the stirring head in real time. Prior art 2 proposes a friction stir welding device. The torque motor stator is fixedly installed in the inner hole of the main shaft, which makes the whole device too bulky. In addition, there is no specific basis for the adjustment of welding parameters during the welding process. However, the technical solution using the PID algorithm has a large time lag and overshoot, and many problems will occur. In addition, none of the existing schemes addresses an important issue, that is, the deviation between the measured values of pressure, vibration, and torque from the real values, and thus does not provide a solution.

[0015] Based on the above understanding, the appli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com