A Friction Stir Welding Tool with Multi-parameter Feedback

A friction stir welding, multi-parameter technology, used in welding equipment, manufacturing tools, non-electric welding equipment, etc., can solve weld defects, weld tail, inability to torque, axial force welding tool attitude detection and control, volume and weight Large and other problems, to achieve the effect of strong practicability, improved welding quality, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

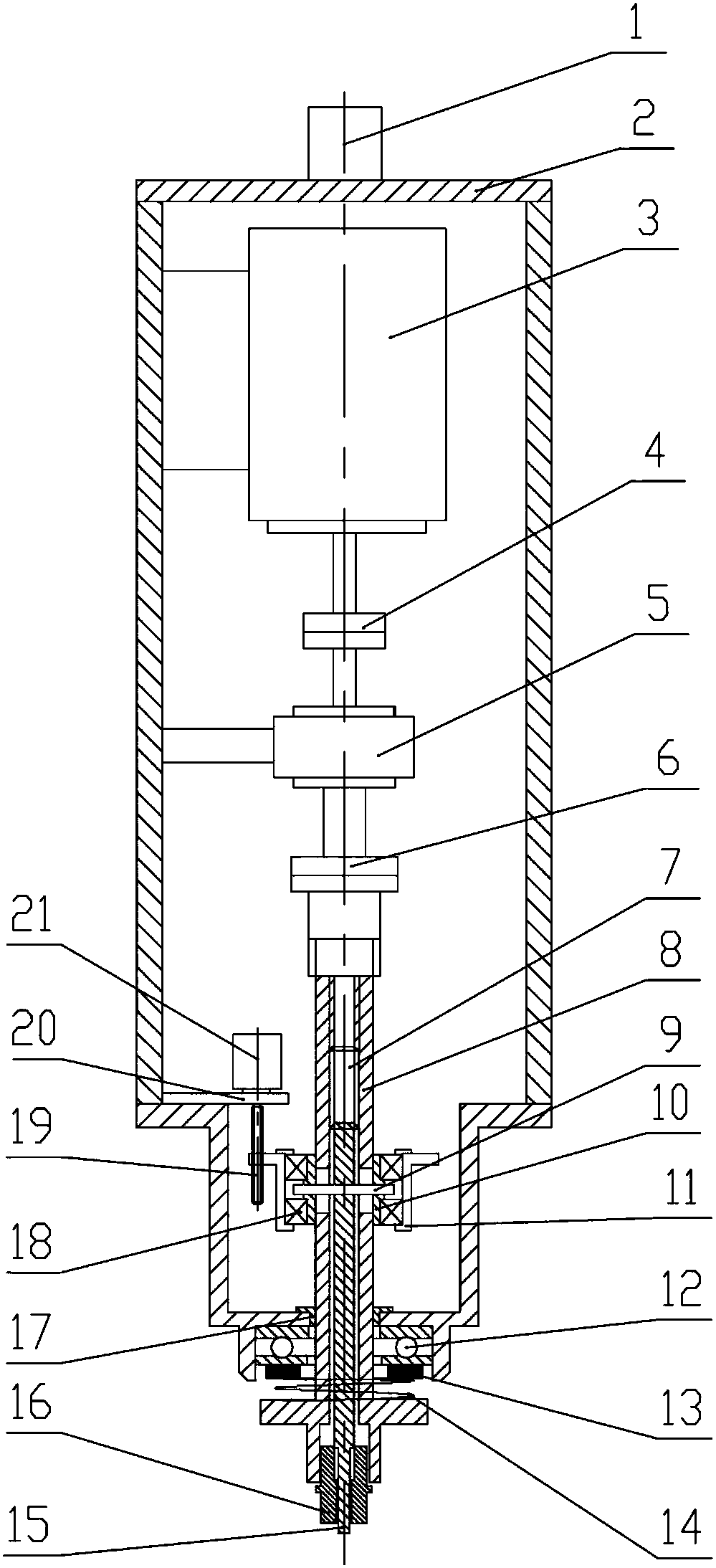

[0016] The present invention will be further described below in conjunction with the accompanying drawings.

[0017] As shown in 1, the friction stir welding tool with multi-parameter feedback of the present invention includes a casing 2, the casing 2 is a cylindrical casing, a mandrel 8 is installed in the casing 2, and the top of the casing 2 is installed with The gyroscope 1 coaxial with the mandrel 8, the mandrel 8 is fixedly connected with the stirring pin 15, the stirring pin 15 is connected with the mandrel 8 through the spline 7, the mandrel 8 is driven to rotate by the power device, and the bottom of the stirring pin 15 is covered with Stirring head shaft shoulder 16, which is fixed on the mandrel 8, the power device includes a main shaft hydraulic motor 3, and the main shaft hydraulic motor 3 is sequentially connected with the drive coupling 4, the torque sensor 5, and the mandrel coupling 6, The mandrel coupling 6 is connected to the mandrel 8, the mandrel 8 is conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com