Solid phase spot welding method

A technology of solid-phase points and solder joints, applied in welding equipment, non-electric welding equipment, metal processing equipment, etc., can solve problems such as inability to fully react, weak connections, solder joints are easily torn and fail, and achieve interface connection quality Improve, improve welding efficiency, increase the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

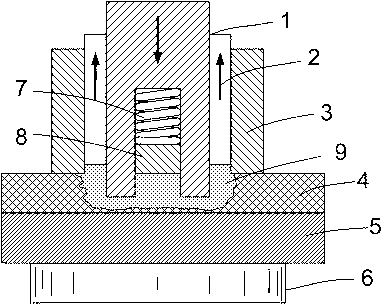

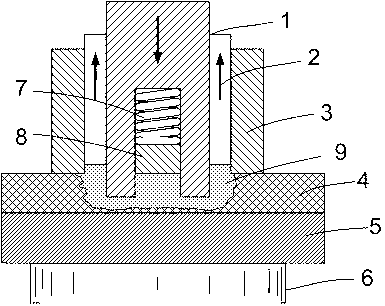

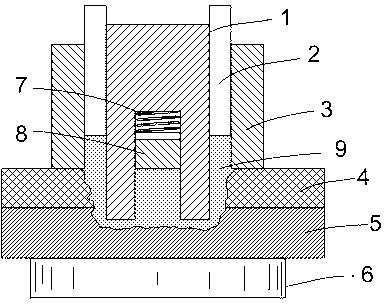

[0031] Such as Figure 1~Figure 6 As shown, the three-ring filled friction spot welding method provided by the preferred embodiment of the present invention comprises the following steps:

[0032] (1) Pressing and preheating step: the outer ring 3 is pressed against the surface of the workpiece, which provides an axial displacement reference for the welding tool and acts as a restraint material. The middle ring 2 and the inner ring 1 are pressed against the surface of the workpiece with the same Rotating at a high speed, the frictional heat generated with the base metal surface will make the surrounding metal reach a plastic softening state.

[0033] (2) Extrusion forging step: while the inner collar 1 rotates at high speed, squeeze the base metal upper plate 4 downward, and discharge the plastic metal 9 to the outside, and the middle collar 2 moves upward while maintaining high-speed rotation, for extrusion At the same time, the spring 7 above the cylindrical slider 8 in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com