Beneficiation method for recovering high iron and high sulfur concentrate from copper tailings containing sulfur and iron

A beneficiation method and copper tailings technology, applied in chemical instruments and methods, wet separation, solid separation, etc., can solve the problems of unsuitability for comprehensive recovery and utilization, large consumption of chemicals, low grade of iron concentrate, etc., to achieve Reduce the consumption of flotation reagents, reduce the number of flotation operations, and ensure the recovery rate of sulfur iron

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

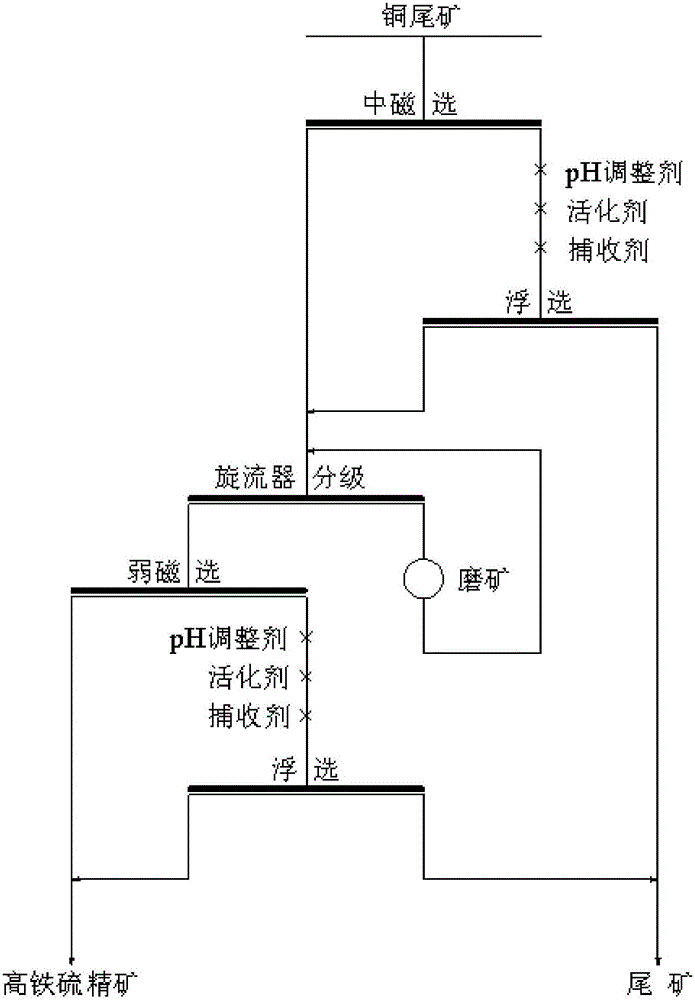

[0026] In order to describe the present invention, the beneficiation method of the present invention for recovering high-iron sulfur concentrate from copper tailings containing sulfur and iron will be further described in detail below in conjunction with the accompanying drawings and examples. S4.20% and TFe10.38% in the copper tailings.

[0027] Depend on figure 1 Shown the present invention from the process flow diagram of the ore dressing method that reclaims high-iron-sulfur concentrate from sulfur-containing, iron-containing copper tailings and finds out that the present invention reclaims the ore-dressing method of high-iron-sulfur concentrate from sulfur-containing, iron-containing copper tailings Adopt the following process and steps:

[0028] 1) Magnetic-flotation pre-enrichment of pyrite in copper tailings: the copper tailings containing sulfur and iron are directly fed into the wet permanent magnetic drum type field strength magnetic separator for magnetic separati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com