Automatic circulation liquid addition system

A technology of automatic circulation and circulation of liquid, which is applied in the separation method, transportation and packaging, dissolution, etc., can solve the problems of cumbersome operation and low efficiency, and achieve the effect of simple and fast operation, high degree of automation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

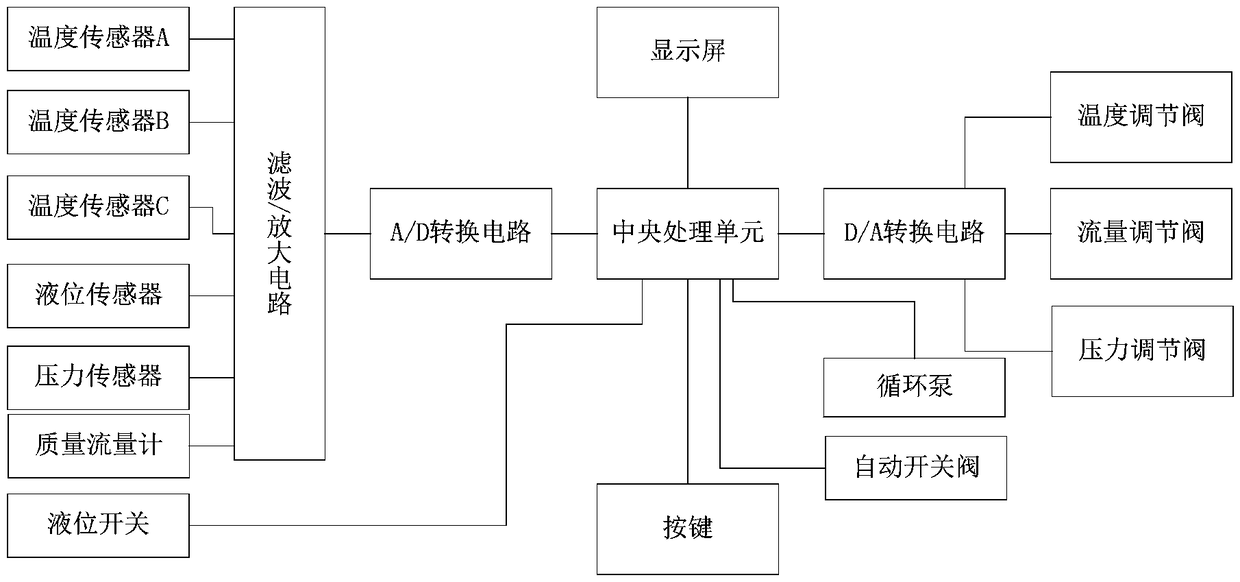

[0025] In order to make the objectives, technical solutions and advantages of the present invention clearer, the present invention will be further described in detail below with reference to the accompanying drawings.

[0026] like figure 1 As shown in the figure, the automatic circulating liquid adding system disclosed in the present invention includes a liquid storage tank 1, a heat exchanger 3, a circulating pump 2, a liquid consumption branch and a controller, and the liquid inlet of the circulating pump 2 is connected to the liquid outlet of the liquid storage tank. The outlet of the circulating pump is connected to the inlet of the heat exchanger 3, and the outlet of the heat exchanger is connected to the circulating liquid inlet 17 of the liquid storage tank 1 through a pipeline. The liquid storage tank 1 is provided with a temperature sensor A22 and a liquid level sensor 20. The upper part of the storage tank 1 is provided with a liquid level switch 19 and an overflow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com