Efficient boiler flue gas treatment device

A technology for boiler flue gas and treatment device, which is used in gas treatment, transportation and packaging, dispersed particle filtration, etc., can solve the problems of large overall energy consumption, complex structure, and inability to purify flue gas, so as to protect the living environment and reduce atmospheric pollution. Good pollution and purification effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

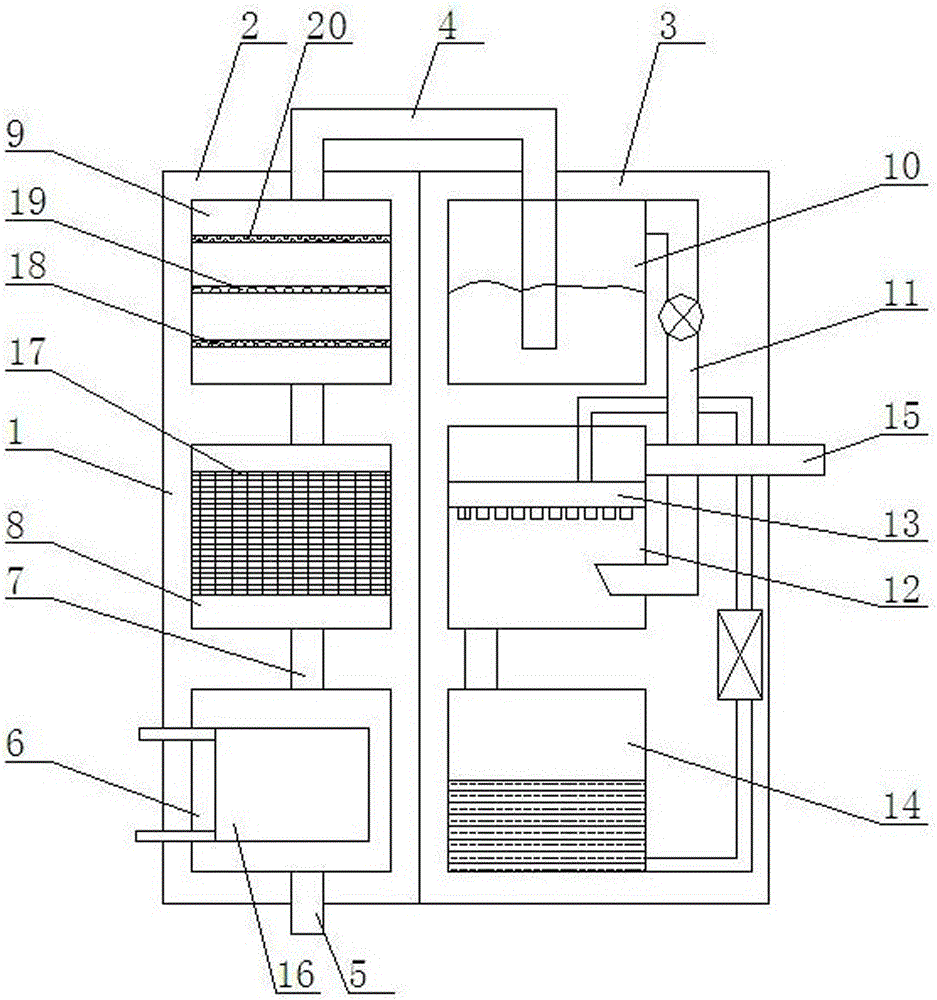

[0018] as shown in the picture 1 As shown, a high-efficiency boiler flue gas treatment device, including a treatment box 1 , left chamber 2 , right chamber 3 , the process box 1 The interior consists of the left box chamber 2 with right chamber 3 constitute, the left box chamber 2 air tube 4 Connect to the right chamber 3 top; said left chamber 2 Bottom unit intake pipe 5 , the left box compartment 2 Internal bottom device cooling chamber 6 , the cooling chamber 6 Bottom connection intake pipe 5 ; The cooling chamber 6 smoke pipe 7 Before connecting the filter cavity 8 ; The front filter cavity 8 smoke pipe 7 filter cavity after connection 9 ; the right chamber 3 Internal upper device denitrification chamber 10 ; The denitrification chamber 10 air tube 4 filter cavity after connection 9 ; The denitrification chamber 10 upper right through the snorkel 11 Connect the lower desulfurization chambe...

Embodiment 2

[0020] as shown in the picture 1 As shown, the cooling chamber 6 Internal device plate heat exchanger 16 。

Embodiment 3

[0022] as shown in the picture 1 As shown, the front filter cavity 8 The internal device is equipped with multi-layer titanium wire weaving filter screen 17 。

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com