Probiotic ice cream and production process thereof

A production process and probiotic technology, applied in frozen desserts, food science, applications, etc., can solve the problems of high cost of probiotic bacteria powder and low number of viable bacteria, achieve stable physical properties and tissue state, delay the melting process, Reduces the effect of recrystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

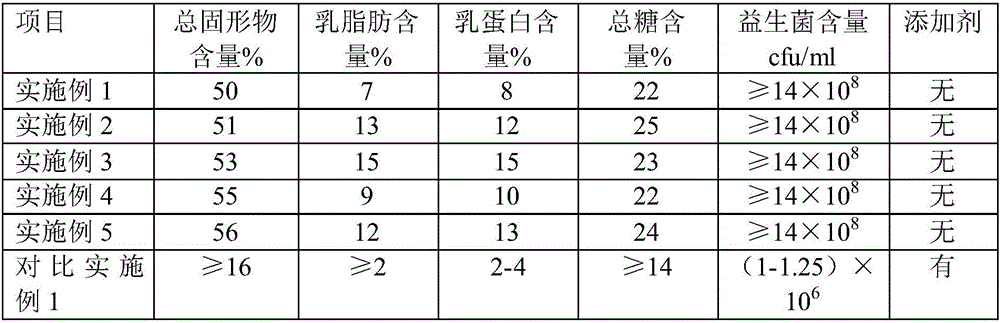

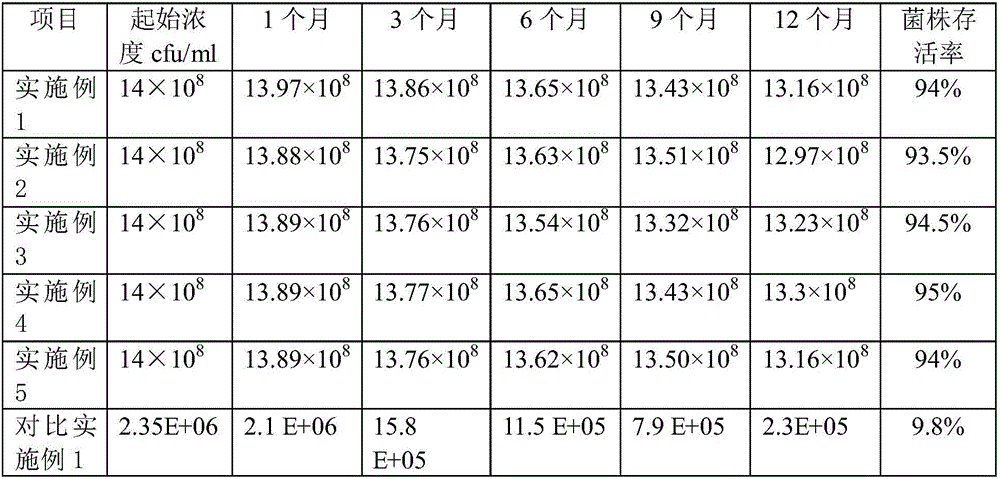

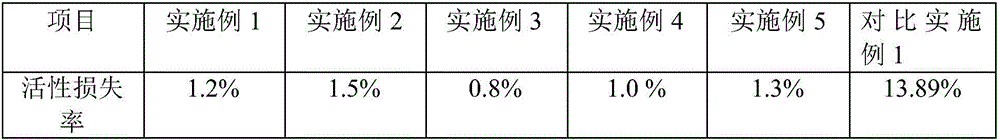

Examples

Embodiment 1

[0025] A probiotic ice cream or ice cream, comprising the following components by mass ratio: whole milk powder 25%, sugar 10%, containing 14×10 per milliliter 8 The above amount of probiotics, the balance is water, wherein the sugar includes 50% white granulated sugar and 50% fructose syrup in terms of mass percentage.

[0026] A production process for probiotic ice cream or ice cream. First, sterilize the equipment and tools used in production with water above 80°C for 30 minutes, and then perform the following operations:

[0027] A. Ingredients: Mix water, white sugar, and whole milk powder evenly to obtain a mixture liquid;

[0028] B. Sterilization: Sterilize the mixture obtained in step A for 10 minutes at 80°C;

[0029] C. Fermentation: Cool down the sterilized mixed material liquid to below 45°C, add probiotics to the material liquid at the ratio of 0.8 g probiotics to 1000 g material liquid, control the fermentation temperature, and ferment for 10-15 hours to obtain...

Embodiment 2

[0033] A probiotic ice cream or ice cream, comprising the following components by mass ratio: 30% whole milk powder, 12% sugar, 14×10 per milliliter 8 The above amount of probiotics, the balance is water, wherein, sugar includes 45% white granulated sugar and 55% fructose syrup in terms of mass percentage.

[0034] A production process for probiotic ice cream or ice cream. First, sterilize the equipment and tools used in production with steam above 80°C for 15 minutes, and then perform the following operations:

[0035] A. Ingredients: Mix water, white sugar, and whole milk powder evenly to obtain a mixture liquid;

[0036] B. Sterilization: Sterilize the mixture obtained in step A for 15 minutes at 85°C;

[0037] C. Fermentation: Cool down the sterilized mixed material liquid to below 45°C, add probiotics to the material liquid at the ratio of 0.85 g probiotics to 1000 g material liquid, control the fermentation temperature, and ferment for 12 hours to obtain a fermented liq...

Embodiment 3

[0041] A probiotic ice cream or ice cream, comprising the following components by mass ratio: whole milk powder 28%, sugar 14%, containing 14×10 per milliliter 8 The above amount of probiotics, the balance is water, wherein, sugar includes 48% white granulated sugar and 52% fructose syrup in terms of mass percentage.

[0042] A production process for probiotic ice cream or ice cream. First, sterilize the equipment and tools used in production with water above 80°C for 20 minutes, and then perform the following operations:

[0043] A. Ingredients: Mix water, white sugar, and whole milk powder evenly to obtain a mixture liquid;

[0044] B. Sterilization: Sterilize the mixture obtained in step A for 12 minutes at 90°C;

[0045] C. Fermentation: Cool down the sterilized mixed material liquid to below 45°C, add probiotics to the material liquid at the ratio of 0.9 g probiotics to 1000 g material liquid, control the fermentation temperature, and ferment for 13 hours to obtain a fer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com