Micro-cultivator transmission mechanism for greenhouse

A technology of transmission mechanism and micro tillage machine, applied in the field of micro tillage machine transmission mechanism and agricultural machinery equipment, can solve the problems of large size, unsuitable for greenhouse planting, high energy consumption, etc., and achieve small size, good cutting efficiency and simple operation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

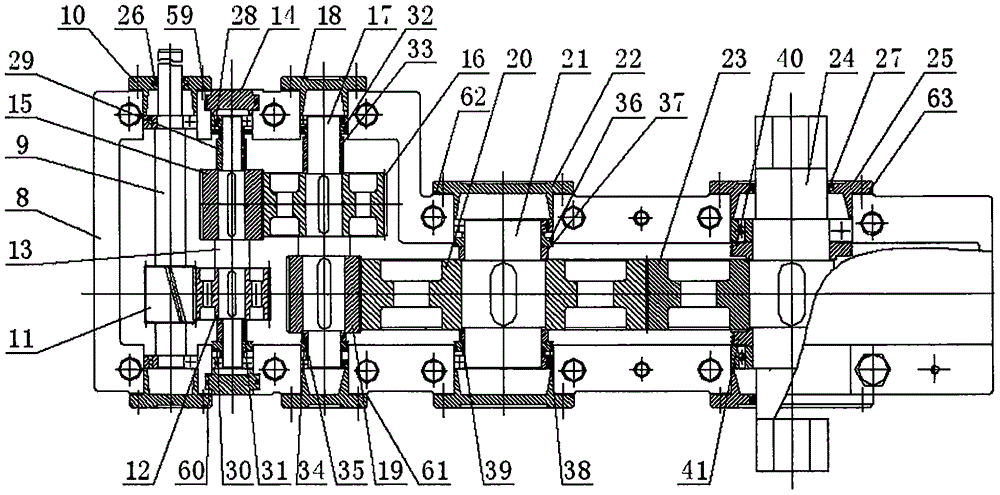

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0020] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 5As shown, a micro-cultivator transmission mechanism for a shed according to the present invention includes a clutch assembly 2 installed on the upper end of the handrail 1, and a reducer assembly 3 is installed on the lower end of the handrail 1. The reducer assembly 3 is connected with the engine assembly 5 through the transmission belt 4, a rotary tiller assembly 6 is installed at the lower end of the reducer assembly 3, and a depth-limiting device assembly 7 is also installed on the shell of the reducer assembly 3. The clutch assembly 2, the engine assembly 5 and the depth stop assembly 7 here can adopt the existing mechanical structure, and the innovation of the present invention is that the described reducer assembly 3 includes a casing 8, and the 8 is installed w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com