Heat conduction film and manufacturing method thereof

A production method and technology of heat conduction film, applied in chemical instruments and methods, semiconductor devices, cooling/ventilation/heating transformation, etc., can solve the problems of high raw material prices, immature technology, and inability to benefit mass products, etc., and achieve low production costs , the effect of a wide range of applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

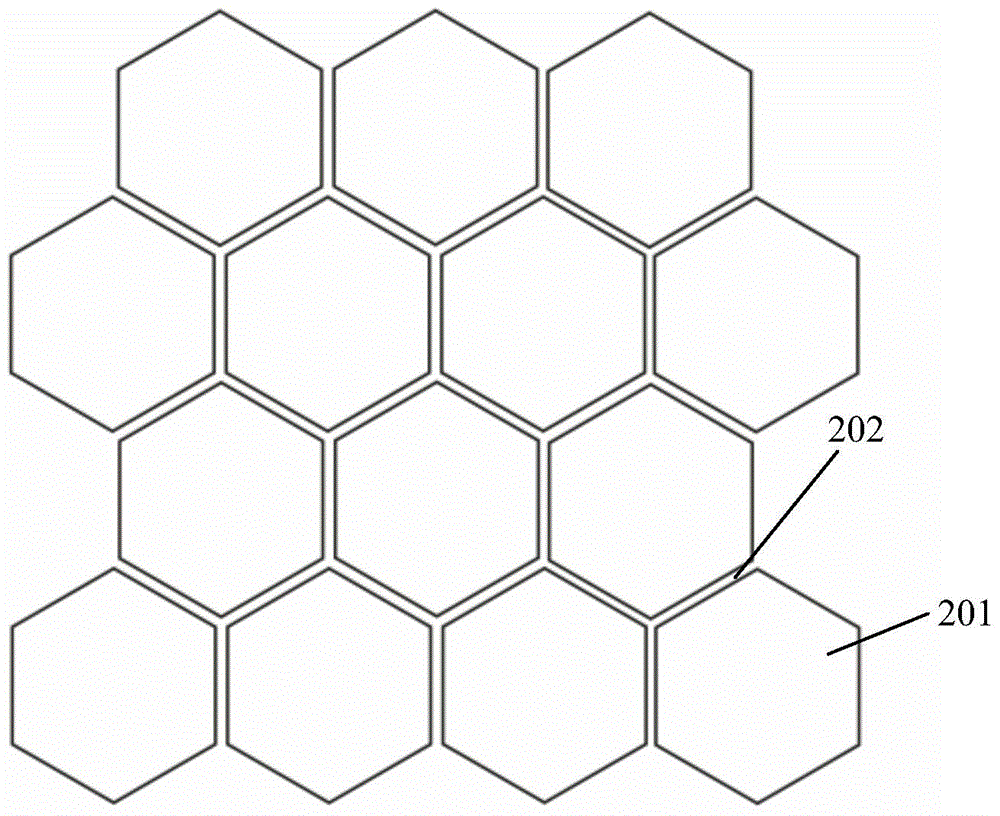

[0032] Such as figure 1 As shown, the thermal conductive film of the present invention, from bottom to top, is the bottom layer 100 of the flexible substrate, the structural layer 200 , the adhesive layer 300 and the surface layer 400 of the flexible substrate.

[0033] combine figure 2 As shown, the structural layer 200 is composed of geometric blocks 201 with protrusions distributed on the bottom surface, and through grooves 202 are formed between adjacent geometric blocks 201 . The groove 202 is filled with a pressure working fluid, and the groove openings around the heat conduction film are blocked.

[0034] The thickness of the bottom layer 100 is 100 microns, the thickness of the structural layer is 30-50 microns, the thickness of the adhesive layer is 20 microns, the thickness of the surface layer 400 is 100 microns, and the width of the groove is 0.5-3 microns. The pressure working fluid fills the entire groove.

[0035] The flexible substrates of the bottom layer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com