Rapid manufacturing and forming integrated device for annular gasket

A ring gasket and manufacturing device technology, applied in the field of mechanical parts manufacturing, can solve the problems that the finished product cannot meet the requirements of standard parts, and achieve the effects of low cost, economical use, and space saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

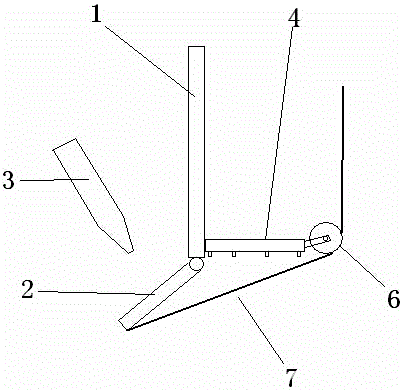

[0026] The preferred technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings.

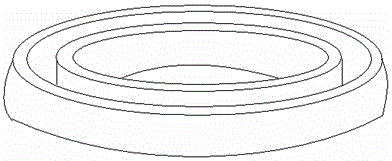

[0027] As shown in the figure, a ring gasket rapid manufacturing integrated device of the present invention includes a rapid manufacturing device and a cooling device. The rapid manufacturing device includes a vertically arranged vertical plate 1, and the vertical plate 1 is also used as the main support of the entire device. A gasket mold 2 is arranged at the bottom end of the vertical plate 1, and the gasket mold 2 is a hollow annular structure. The gasket mold 2 is provided with a ring opening along the annular structure, and the edge of the gasket mold 2 is hinged on the bottom end of the vertical plate 1. ;

[0028] One side of the vertical plate 1 is provided with a plastic nozzle 3 for injection into the annular mouth of the gasket mold 2;

[0029] The other side of the vertical plate 1 is provided with an ejection mechani...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com