Mixed template synthesis of high silica cu-cha

A technology for synthesizing zeolites and reaction mixtures, applied in molecular sieves and base exchange compounds, inorganic chemistry, molecular sieve catalysts, etc., can solve problems such as lack of metal loading, catalyst stability and activity effects, and harmful hydrothermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0087] Example 1: Synthesis of JMZ-3 Zeolite Using One-Pot Mixed-Template Method

[0088] Catalysts obtained by the mixed-template one-pot synthesis procedure described here demonstrate significantly improved quality compared to catalysts obtained by single-template synthesis.

[0089] Here, alkali hydroxide (NaOH) and organic templating agent (DMECHA) were combined in water and mixed for about 5 minutes. Aluminum source (Al(OEt) 3 ) was added to the mixture and mixed for approximately 5 minutes. SiO2 source (SiO 2 ) was added to the mixture and mixed until a homogeneous mixture was formed. Afterwards, seeds (eg, CHA zeolite), Cu source, and TEPA were added to the mixture and mixed for approximately 30 minutes. The resulting mixture was heated at 160°C for about two days. At the end of this heater, the solid was collected by vacuum filtration, rinsed with deionized water and dried at about 100°C for about overnight. The resulting molecular sieve catalyst material was cal...

Embodiment 2

[0090] Example 2: Sodium-free synthesis of JMZ-3 zeolite using a one-pot mixed-template approach

[0091] Na-free synthesis can be achieved by varying the template ratio and the total template / silica ratio. Sodium-free JMZ-3 was prepared using the general procedure from Example 1, but using the synthesis mixture shown in Table 2.

[0092] Table 1 Molar composition of starting synthesis mixture

[0093]

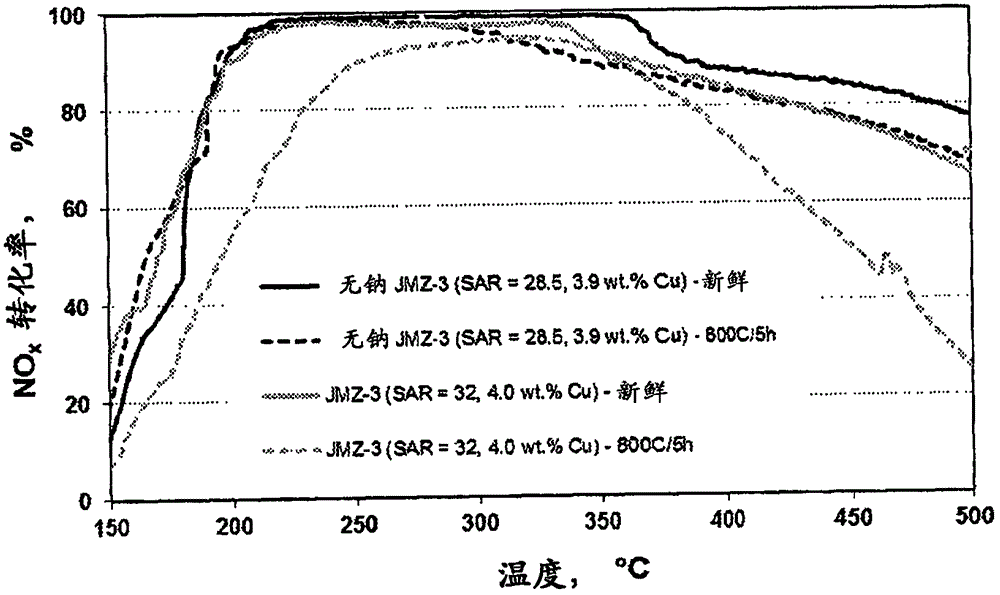

[0094] Sodium-free JMZ-3 showed better overall NO after hydrothermal aging compared to JMZ-3 with sodium x conversion rate (see figure 1 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com