Composite structure of lithium battery pack

A technology of combined structure and lithium battery pack, applied in battery pack parts, structural parts, non-aqueous electrolyte batteries, etc., can solve the problems affecting the service life of lithium batteries, safety accidents, heat accumulation, etc., to achieve compact structure and extended use. The effect of longevity and simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

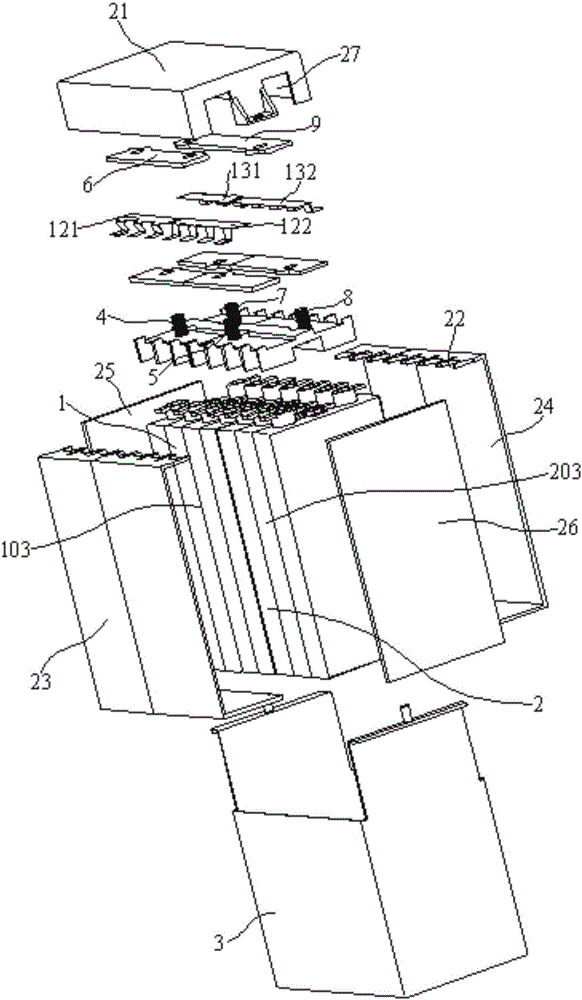

[0027] Embodiment 1: A combined structure of a lithium battery pack, including a first lithium battery assembly 1, a second lithium battery assembly 2 and a casing 3, the first lithium battery assembly 1 and the second lithium battery assembly 2 are embedded in the casing Inside the body 3, the first positive pole guide post 4 of the first lithium battery assembly 1 is electrically connected to the second positive pole guide post 5 of the second lithium battery assembly 2 through the positive pole guide post connecting sheet 6, and the first lithium battery assembly The first negative pole guide post 7 of 1 is electrically connected to the second negative pole guide post 8 of the second lithium battery assembly 2 through the negative pole guide post connecting sheet 9;

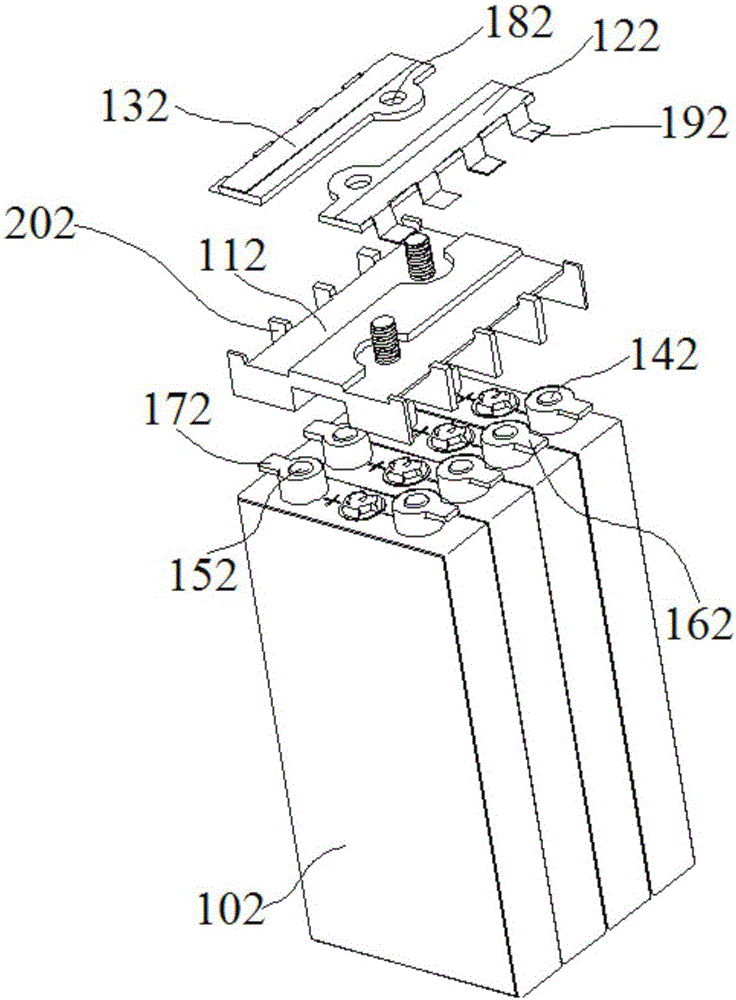

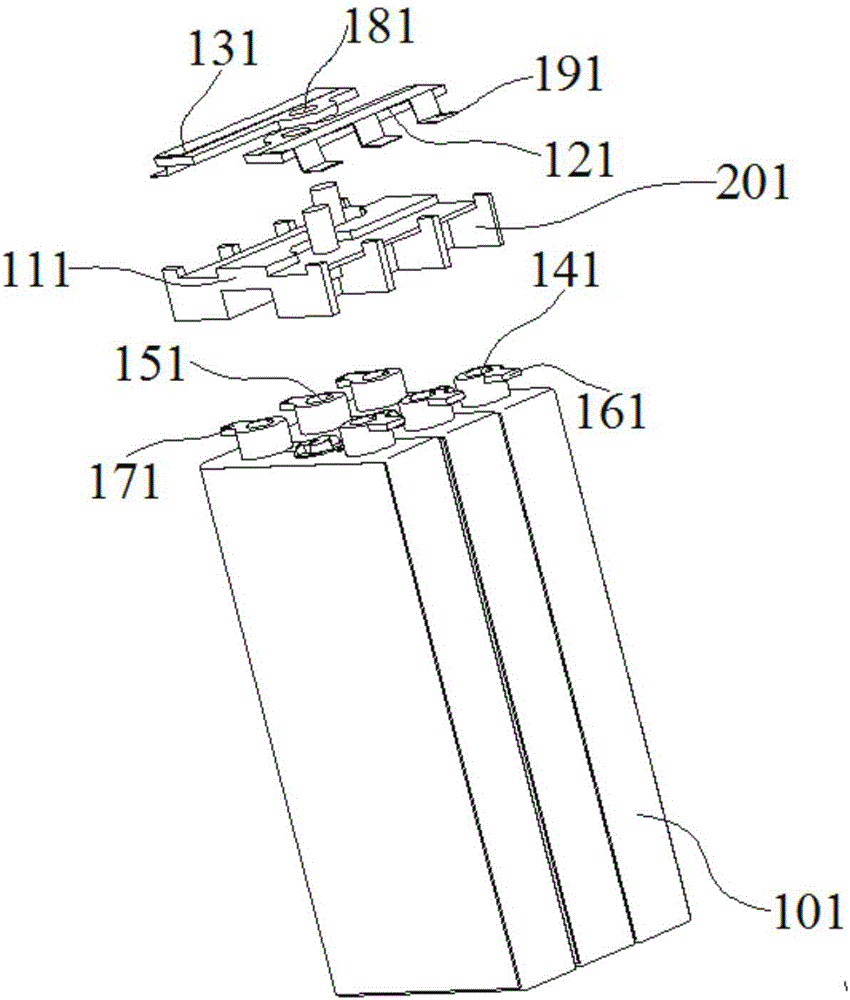

[0028] The first lithium battery assembly 1 further includes a first lithium battery pack 103 composed of several first lithium batteries 101 arranged side by side, a first insulating clamp 111 , a first positi...

Embodiment 2

[0037] Embodiment 2: A combined structure of a lithium battery pack, including a first lithium battery assembly 1, a second lithium battery assembly 2, and a casing 3, and the first lithium battery assembly 1 and the second lithium battery assembly 2 are embedded in the casing Inside the body 3, the first positive pole guide post 4 of the first lithium battery assembly 1 is electrically connected to the second positive pole guide post 5 of the second lithium battery assembly 2 through the positive pole guide post connecting sheet 6, and the first lithium battery pack The first negative pole guide post 7 of 1 is electrically connected to the second negative pole guide post 8 of the second lithium battery assembly 2 through the negative pole guide post connecting sheet 9;

[0038] The first lithium battery assembly 1 further includes a first lithium battery pack 103 composed of several first lithium batteries 101 arranged side by side, a first insulating clamp 111 , a first posit...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap