Structural layer thickness design method for mixed base course cement concrete pavement

A cement concrete and hybrid technology, applied in computing, special data processing applications, instruments, etc., can solve problems such as being too conservative and not scientifically reasonable in design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

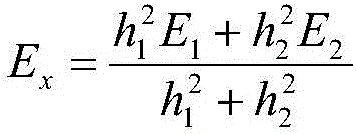

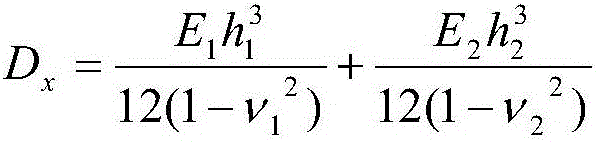

[0052] The reference period for cement concrete pavement construction of an expressway is 30 years, the target reliability is 95%, and the safety level is first class. The proposed pavement structure form is: ordinary concrete surface (elastic modulus E c , thickness h c , Poisson's ratio v c , the standard value of bending and tensile strength is f r )+4cm asphalt concrete interlayer+roller compacted concrete base (elastic modulus E 1 , thickness h 1 , Poisson's ratio v 1 , the standard value of bending and tensile strength is f r1 )+cement-stabilized macadam subbase (elastic modulus E 2 , thickness h 2 , Poisson's ratio v 2 )+ graded crushed stone layer (elastic modulus E a , thickness h a ).

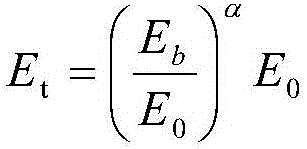

[0053] According to the rebound modulus of the subgrade soil and the distance between the top of the road bed and the groundwater level, determine the comprehensive rebound modulus E of the road bed top 0 , and then according to the elastic modulus E of the pellet layer a...

Embodiment 2

[0082] The reference period for cement concrete pavement construction of an expressway is 30 years, the target reliability is 95%, and the safety level is first class. The proposed pavement structure form is: ordinary concrete surface (elastic modulus E c , thickness h c , Poisson's ratio v c , the standard value of bending and tensile strength is f r )+4cm asphalt concrete interlayer+roller compacted concrete base (elastic modulus E 1 , thickness h 1 , Poisson's ratio v 1 , the standard value of bending and tensile strength is f r1 )+ densely graded asphalt stabilized macadam subbase (elastic modulus E 2 , thickness h 2 , Poisson's ratio v 2 )+ graded crushed stone layer (elastic modulus E a , thickness h a ).

[0083] According to the rebound modulus of the subgrade soil and the distance between the top of the road bed and the groundwater level, determine the comprehensive rebound modulus E of the road bed top 0 , and then according to the elastic modulus E of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com