An Adaptive Control Method of Die Production Process Based on Dynamic Kanban

An adaptive control and production process technology, applied in the direction of electrical program control, comprehensive factory control, comprehensive factory control, etc., can solve the complexity of parts manufacturing, increase the failure rate of various equipment, frequent design changes and process parameter changes, and process Problems such as the large difference between routes and processing hours have achieved the effect of breaking through application limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

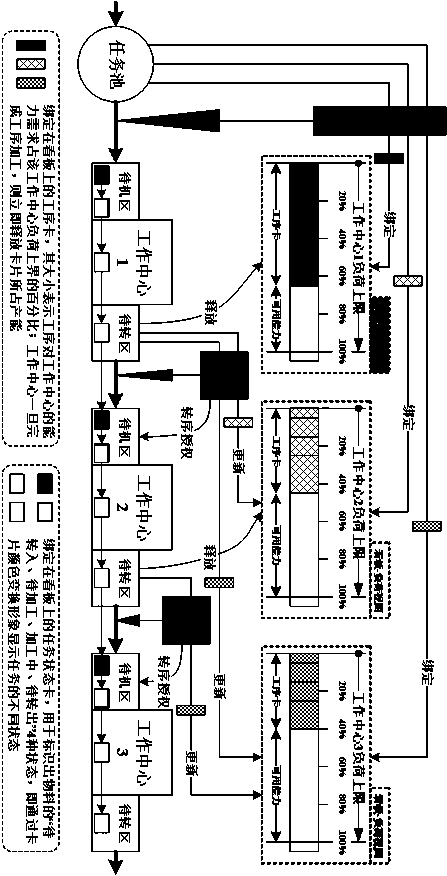

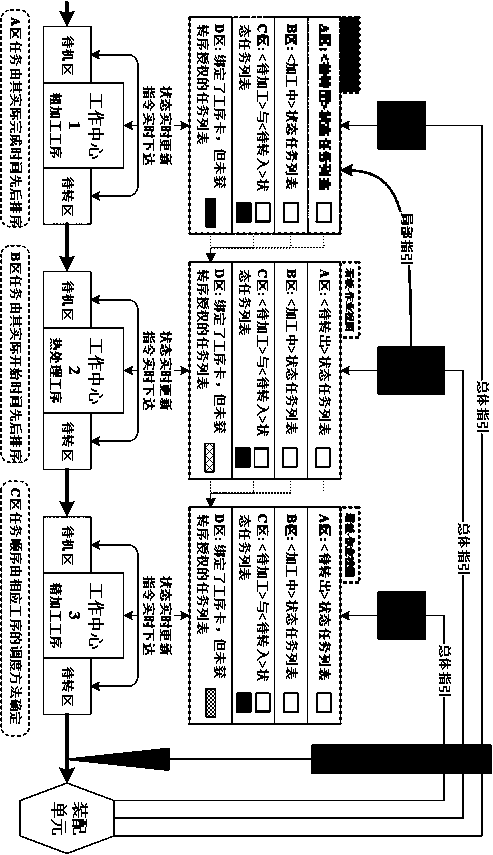

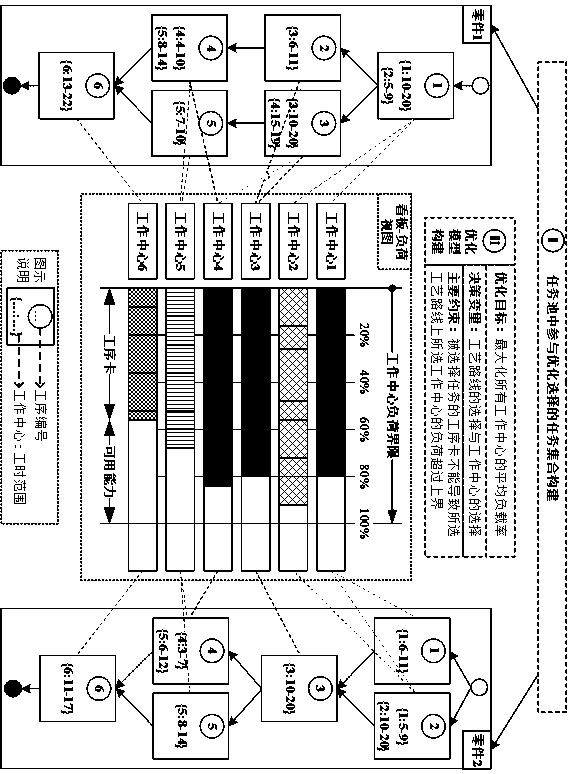

[0050] The specific implementation of the present invention will be described in detail below in conjunction with the accompanying drawings. As a part of this specification, the principles of the present invention will be described through examples. Other aspects, features and advantages of the present invention will become clear through the detailed description. In the referenced drawings, the same reference numerals are used for the same or similar components in different drawings. In order to make the present invention easier to understand, specific embodiments of the present invention will be further described below.

[0051] Based on the system dynamics point of view, the goal of adaptive production control is to make the manufacturing system stay in a steady state for a relatively long time, while the time in an unsteady state is relatively short, that is, the manufacturing system needs to be able to quickly transform to a steady state when it is in an unsteady state . ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com