Measuring device and method for geometric size distribution of needle damage loci of KDP crystal

A technology of geometry and measurement device, applied in measurement devices, analytical materials, optical testing flaws/defects, etc., can solve the problems of increased crystal scattering loss, damage to downstream optical components, and increased beam ratio downstream of the crystal, etc., to improve the measurement Accuracy, the effect of eliminating the birefringence effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

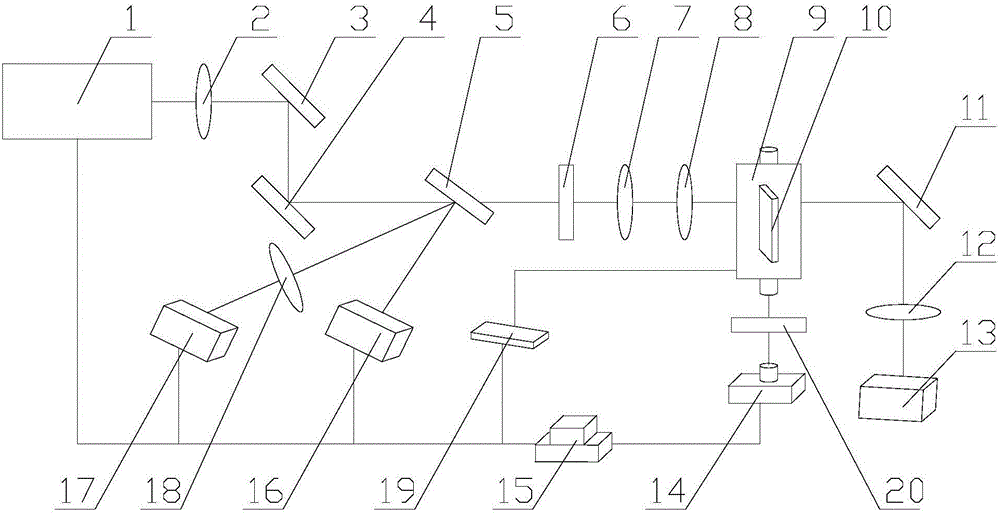

[0064] A measuring device for measuring the geometric size distribution of needle-shaped damage points in KDP crystals, including a test laser 1, an energy attenuation device 2, a first reflector 3, a second reflector 4, an optical wedge 5, a first polarizer 6, a half-wave Sheet 7, second cylindrical lens 8, three-dimensional translation stage 9, third mirror 11, third cylindrical lens 12, detection laser 13, microscope 14, PC computer 15, energy meter 16, CCD camera 17, first cylindrical lens 18 , controller 19 and first polarizer 20;

[0065] The test light generated by the test laser 1 passes through the energy attenuation device 2, the first reflector 3, and the second reflector 4 in turn, and then enters the optical wedge 5, and a part of the test light is reflected on the front surface of the optical wedge 5 to form the first reflection Test light, the first reflected test light is imaged to the CCD camera 17 after the first cylindrical lens 18; a part of the test light ...

Embodiment 2

[0067] On the basis of the first embodiment, the probe light incident on the sample 10 to be tested and the transmitted test light incident on the sample 10 to be tested are transmitted collinearly in opposite directions.

Embodiment 3

[0069] On the basis of Embodiment 1 or Embodiment 2, the detection laser 13 is a white light source or a broadband light source.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com