Determination instrument and determination method for osmotic coefficients of drilling and coring test part

A permeability coefficient, drilling core technology, applied in permeability/surface area analysis, instruments, measuring devices, etc. The effect of shortening the test time, simple structure and small test error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

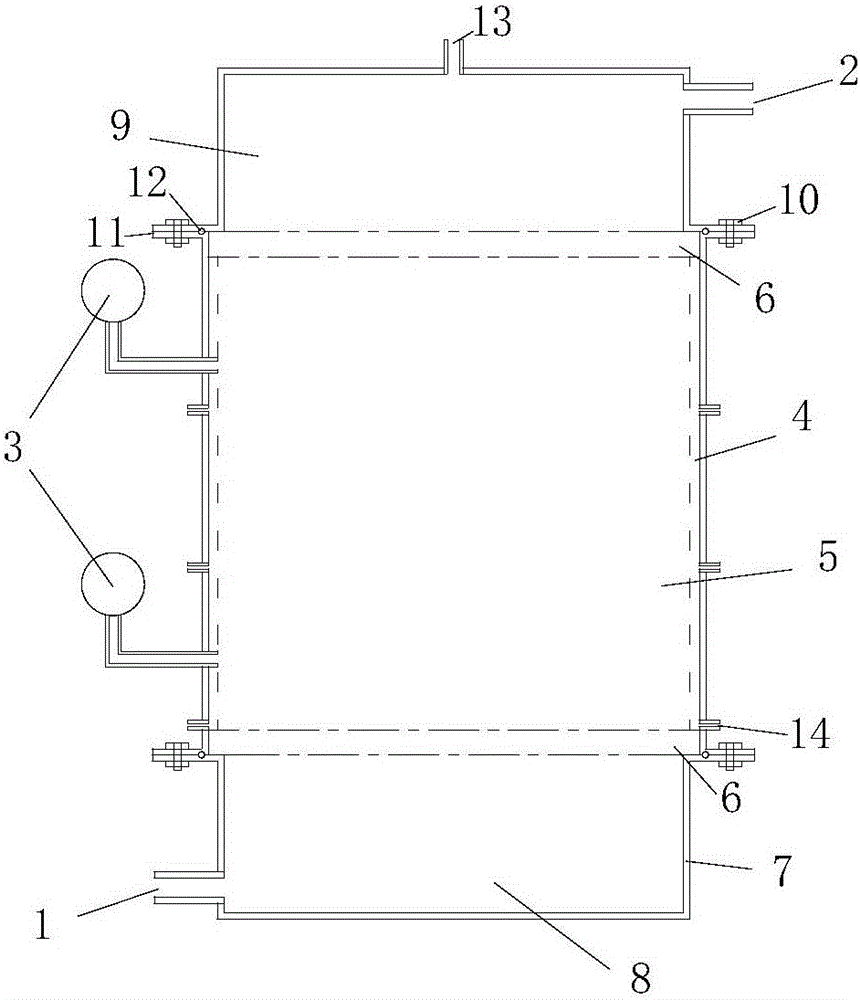

[0026] The present invention will be further explained below in conjunction with specific embodiments and accompanying drawings.

[0027] see figure 1 , the measuring instrument of the present invention comprises the water outlet buffer zone 9, the test chamber body 5 and the water inlet buffer zone 8 arranged successively from top to bottom. The blue plate 11 is fixedly connected by fixing screws 10, and the joints between the water outlet buffer zone 9 and the water inlet buffer zone 8 and the test chamber 5 are sealed with a sealing rubber ring 12 to form a closed cavity, and the water outlet buffer zone 9 and the water inlet The connecting parts of the buffer zone 8 and the test cavity 5 are all provided with table tops for supporting the permeable layer. The upper end of the side wall of the water outlet buffer zone 9 is provided with a water outlet 2, and the top of the water outlet buffer zone 9 is provided with an air extraction hole 13, and the air extraction hole 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com