Machine room cooling system provided with set-top type units

A heat dissipation system, top-mounted technology, applied in air-conditioning systems, household heating, heating methods, etc., can solve the problems of insufficient use of hot air rising, high fan power, long distance of sending and returning air, etc., to save internal space , space-saving and low wind resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

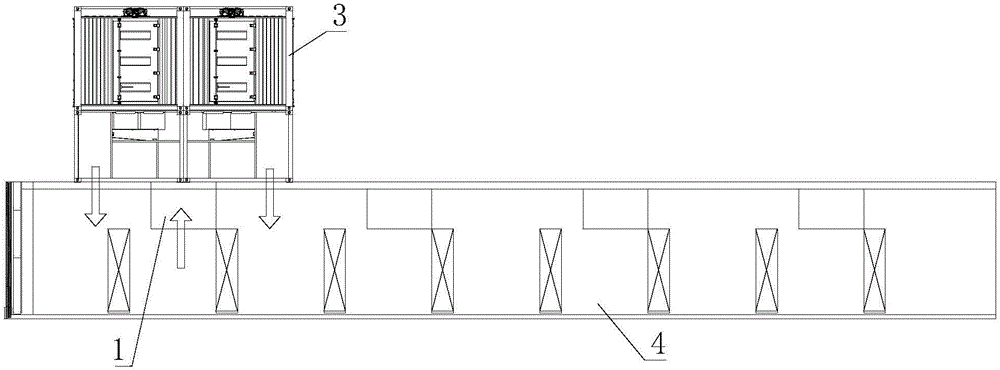

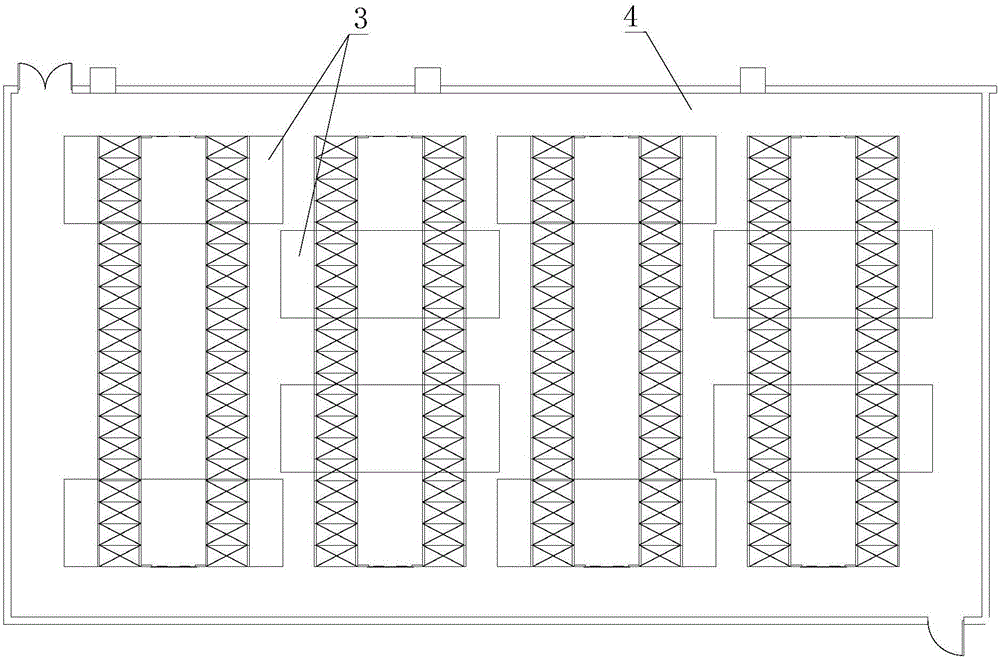

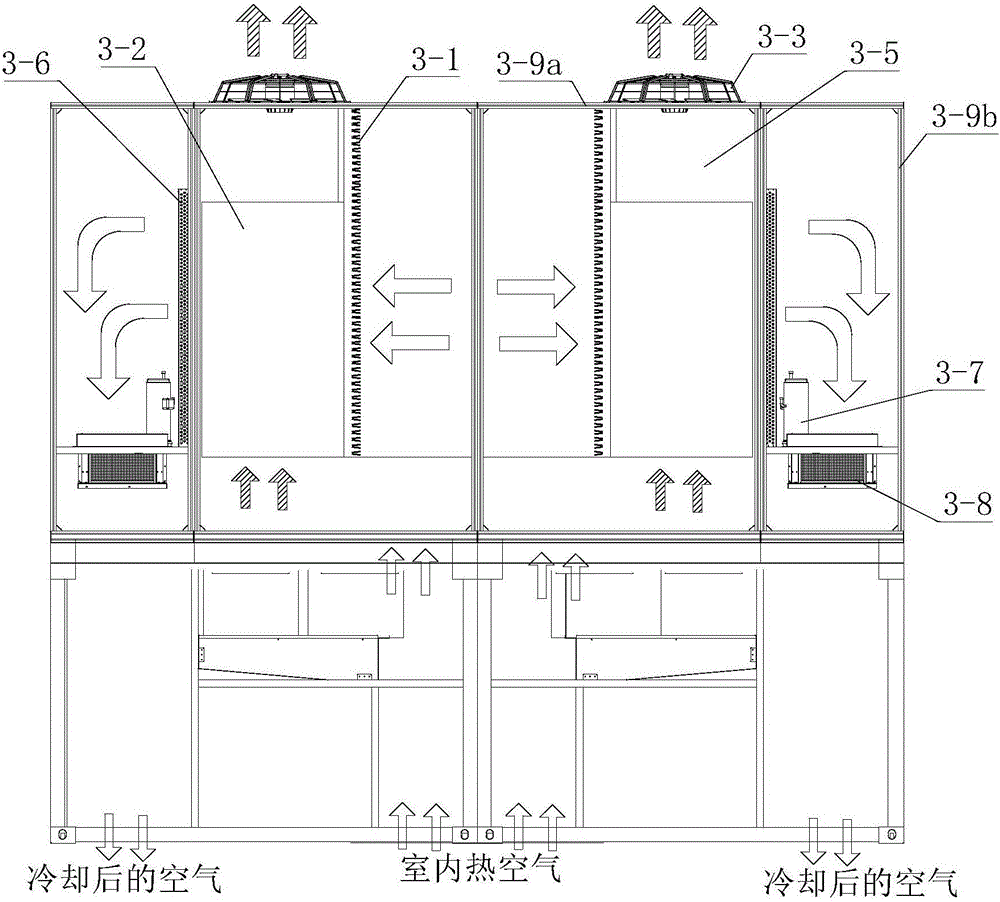

[0028] Such as figure 1 and figure 2 As shown, the heat dissipation system of the computer room in this embodiment includes multiple groups of heat dissipation units 3 arranged outside the top of the computer room 4. For a brief display, figure 1 Only one group of cooling units 3 is shown in the figure. The heat dissipation unit 3 has an air inlet connected to the machine room and an air supply port connected to the machine room. The air inlet and the air supply port are located at the bottom of the heat dissipation unit. The heat dissipation unit 3 also has an outdoor air inlet and an outdoor air outlet connected to the outdoor environment. An outdoor air flow channel is formed in the heat dissipation unit between the outdoor air inlet and the outdoor air outlet, and an indoor air flow channel is formed in the heat dissipation unit between the air inlet and the air supply port, and the outdoor air flow channel and the indoor air flow channel are isolated from each other.

...

Embodiment 2

[0038] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that this embodiment is a system in which the heat dissipation unit is applied to a closed cold aisle, and Embodiment 1 is a system in which a heat dissipation unit is applied to a closed hot aisle. The indoor air cooled by the heat dissipation unit 3 is discharged into the closed cold aisle 2 from the air outlet at the bottom of the heat dissipation unit 3 . Cooling unit 3 can be arranged left and right ( Figure 4 ), can also be arranged front and back ( Figure 7 ).

[0039] When the closed cold aisle is installed in the computer room, the air cooled by the heat dissipation unit enters the computer room from the air supply port of the heat dissipation unit through the closed cold aisle to cool down the server and other equipment; the hot return air generated by the equipment diffuses into the heat dissipation unit for cooling. Cool down. Similarly, the favorable airflow organiz...

Embodiment 3

[0041] Such as Figure 8 As shown, the difference between this embodiment and Embodiment 1 is that the natural cold source cooling module also includes a spray device 3-4, and the heat exchange and cooling effect is enhanced through the spray device. The spray device 3-4 of this embodiment is set Above the evaporative cooling heat exchanger 3-2, the spraying device 3-4 is connected to the spraying water circulation system (not shown) through a pipeline, and the cooling water is provided by the spraying water circulation system, and the water is sprayed until the evaporation Cooling on heat exchanger 3-2. The spray water circulation system includes a water pump connected by pipes, a water receiving tray and an external supply water source, and the water receiving tray is located below the evaporative cooling heat exchanger 3-2.

[0042] The heat dissipation system of the present invention can be applied to a data machine room with closed hot aisles and / or closed cold aisles. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com