Method for controlling caving of roof of short distance coal bed roadway

A roadway roof and short-distance technology, which is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., can solve the problems of low caving arch, impact, simplified and single roof caving arch shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

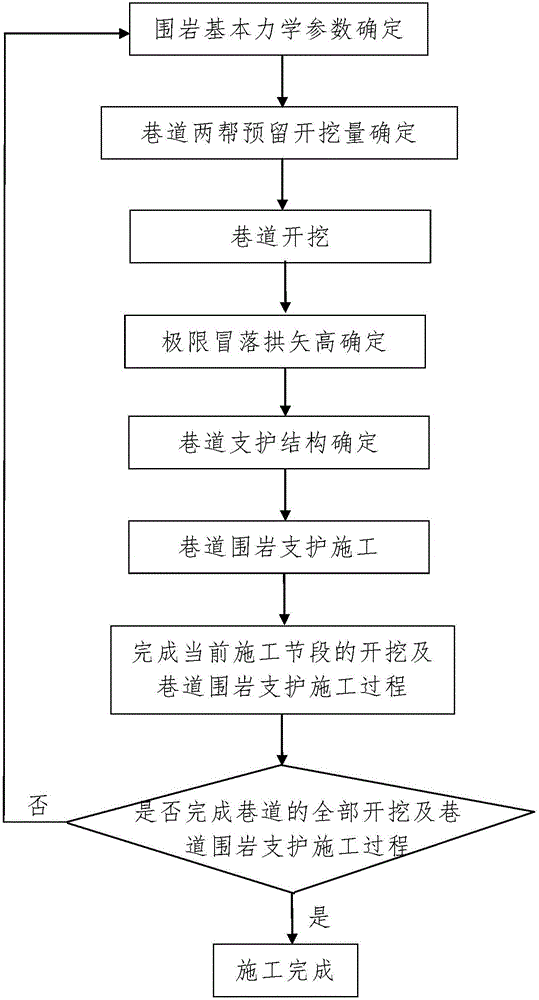

[0069] Such as image 3 A method for preventing and preventing the roof caving of a short-distance coal seam roadway is shown, and the short-distance coal seam roadway 1 is excavated and the roadway surrounding rock support construction is carried out in multiple segments along the longitudinal extension direction of the roadway from the back to the front; The cross-section of the coal seam roadway 1 is rectangular and it is a roadway mined in the lower coal seam 2, and the close coal seam roadway 1 is located under one side of the upper coal seam roadway 3, and the upper coal seam roadway 3 is mined in the upper coal seam 4 The roadway, the upper coal seam 4 is located above the lower coal seam 2, and the upper coal seam 4 and the lower coal seam 2 are separated by an interlayer 5, the thickness of the interlayer 5 is D, wherein 15m≤D<30m; the short distance The coal seam roadway 1 and the upper coal seam roadway 3 are arranged in parallel; one side of the upper coal seam roa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Longitudinal length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com