Automatic control cutter with overload protection function

An overload protection and cutting machine technology, applied in the field of road construction equipment and construction, can solve the problems that the cutting machine is not equipped with overload protection, reduce the technical requirements of operators, and cut incompletely, so as to prevent deformation and damage due to stress and increase overload protection. , to avoid the effect of secondary construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

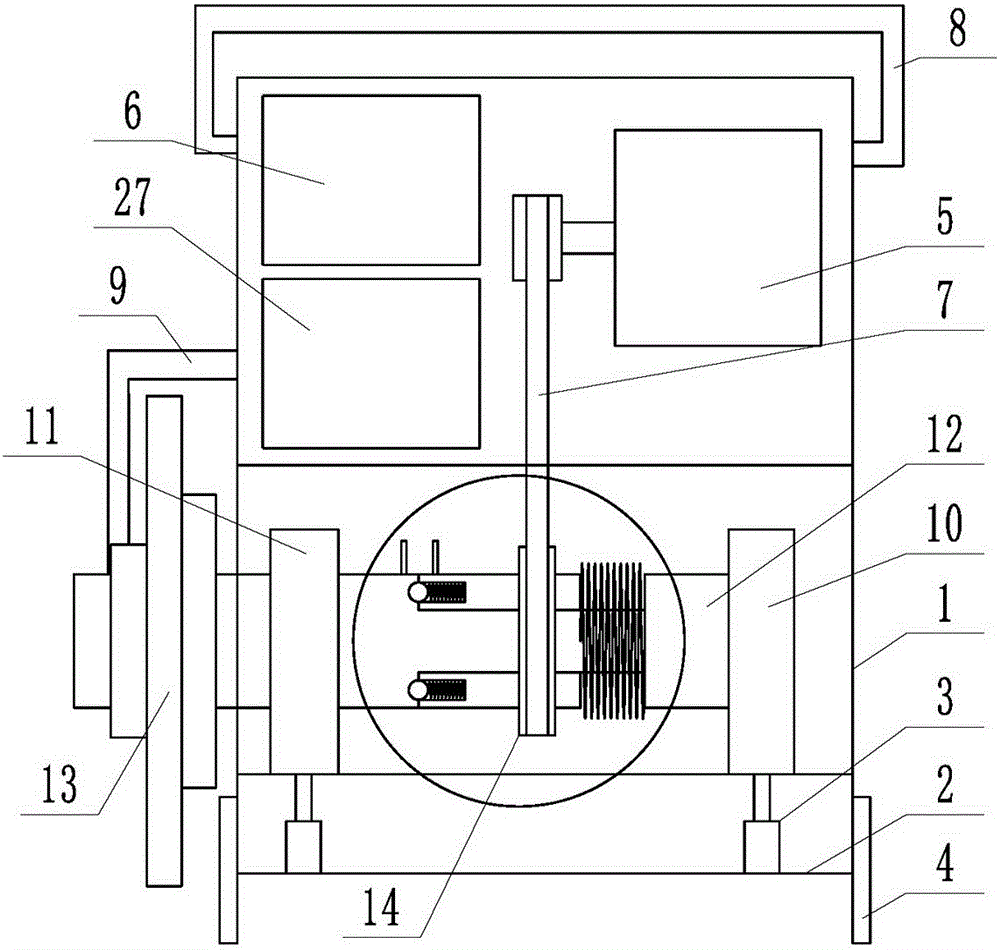

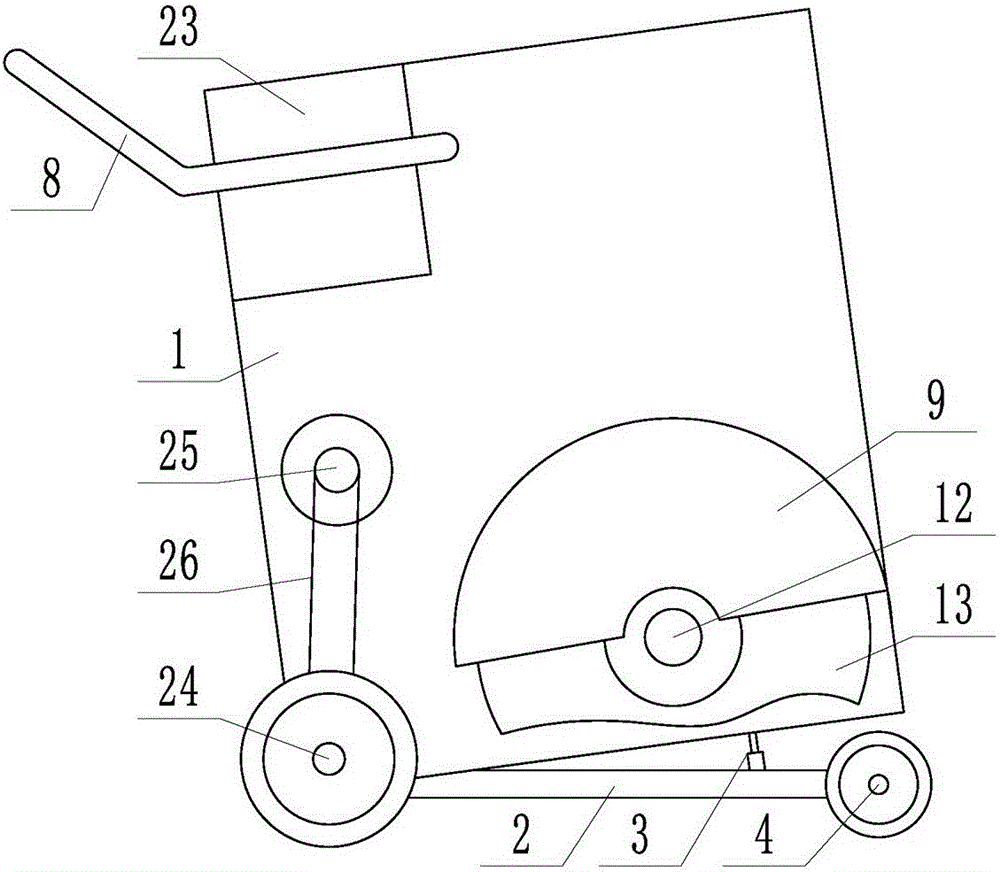

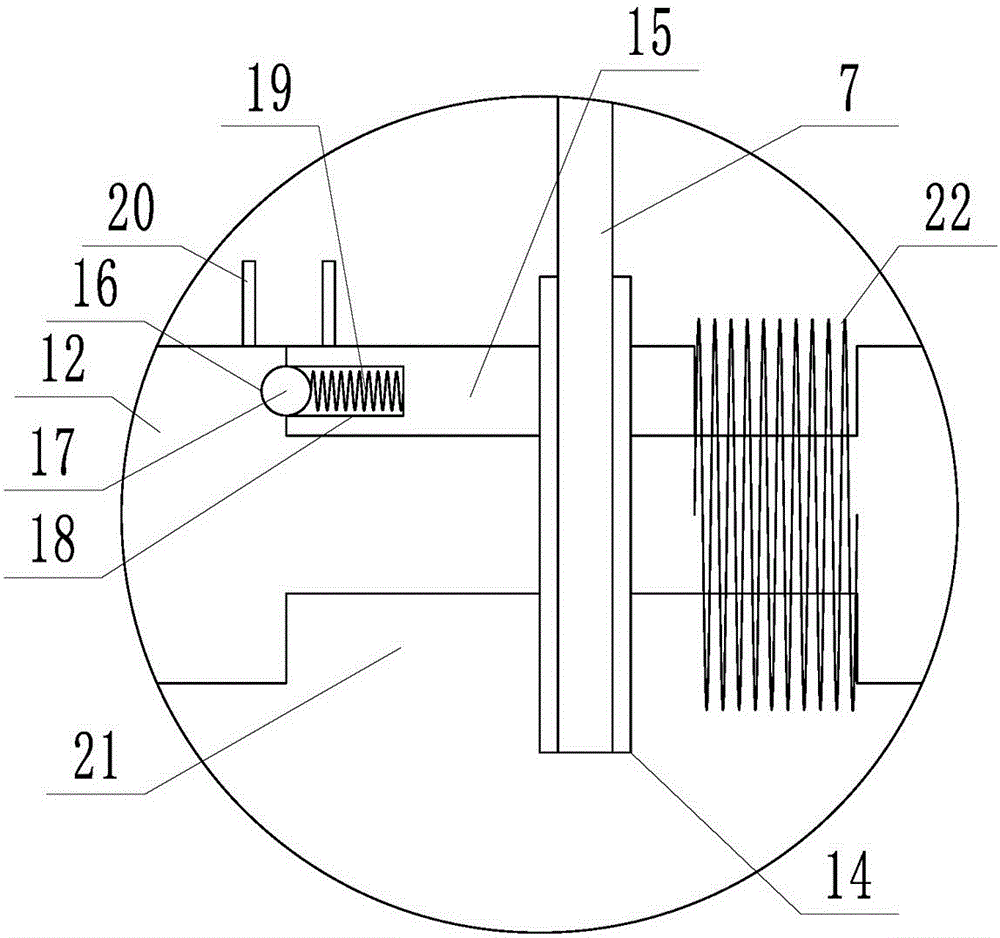

[0012] Depend on Figure 1 to Figure 3 Provide, the present invention comprises frame 1, push handle 8, front wheel 4, trailing wheel 24, cutting piece 13, oil cylinder 6, storage battery 27 and engine 5, it is characterized in that, frame 1 lower end is hinged with base plate 2, base plate 2 An electric push rod 3 is connected with the frame 1 to form a structure in which the electric push rod 3 adjusts the angle between the bottom plate 2 and the frame 1. The oil cylinder 6, the storage battery 27 and the engine 5 are installed on the upper side of the frame 1, and the frame 1, the first fixed frame 11 and the second fixed frame 10 are fixed on the bottom, the first fixed frame 11 and the second fixed frame 10 are pierced with a rotating shaft 12, and the middle section of the rotating shaft 12 is provided with a mount...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com