Transfer coating ink-jet printing high-gloss photographic paper

An inkjet printing, high gloss technology, applied in coating, printing, papermaking, etc., can solve the problems of photo paper performance to be improved, environmental protection burden, low production efficiency, etc. The effect of increased production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

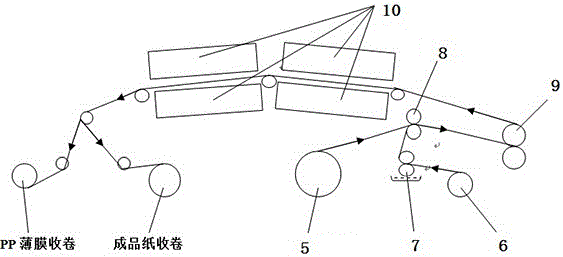

Image

Examples

Embodiment 1

[0056] 1. When preparing the primer coating, add light calcium carbonate at a ratio of 25% to 75% deionized water to start the dispersing machine. During the dispersion process, add 0.6% polycarboxylate sodium salt dispersant, and then add in order after dispersing for 20 minutes. Add 6% polyvinyl acetate emulsion adhesive, 8% polyvinyl alcohol glue, and 0.3% color fixing agent Y. After adding all of them, continue stirring for 15 minutes to complete the preparation.

[0057] 2. The preparation of the top coating is to use water-based silica sol as the main body, add 12% of polyvinyl alcohol glue with a solid content of 10%, and 0.2% of color-fixing agent Y, stir well and set aside.

[0058] 3. Preparation of back-coating paint Add 3% polyvinyl alcohol to 95% deionized water, stir and disperse fully, then turn on steam and heat to gelatinize under continuous stirring state, heat gelatinization time for 30 minutes, the colloid is colorless and transparent. OK, cool to room temp...

Embodiment 2

[0063] The primer coating includes light calcium carbonate, polycarboxylate sodium salt dispersant, polyvinyl acetate emulsion adhesive, polyvinyl alcohol glue and color fixing agent;

[0064] Topcoat coatings include water-based silica sol and polyvinyl alcohol glue;

[0065] Backcoat paints include polyvinyl alcohol.

[0066] The formula of primer coating comprises by following parts by weight: 26 parts of light calcium carbonate, 73 parts of deionized water, 0.5 part of polycarboxylate sodium salt type dispersant, 5 parts of polyvinyl acetate emulsion adhesive, polyvinyl alcohol glue 8 parts, 0.5 parts of color fixing agent.

[0067] The preparation method of the primer coating is: adding light calcium carbonate to deionized water according to the above weight parts, adding polycarboxylate sodium salt type dispersant during the dispersion process of starting the disperser, and adding polyvinyl acetate in sequence after dispersing for 20 minutes The emulsion adhesive, poly...

Embodiment 3

[0072] The primer coating includes light calcium carbonate, polycarboxylate sodium salt dispersant, polyvinyl acetate emulsion adhesive, polyvinyl alcohol glue and color fixing agent;

[0073] Topcoat coatings include water-based silica sol and polyvinyl alcohol glue;

[0074] Backcoat paints include polyvinyl alcohol.

[0075] The formula of primer coating comprises by following parts by weight: 28 parts of light calcium carbonate, 72 parts of deionized water, 0.9 part of polycarboxylate sodium salt type dispersant, 8 parts of polyvinyl acetate emulsion adhesive, polyvinyl alcohol glue 11 parts, 0.6 parts of color fixing agent.

[0076] The preparation method of the primer coating is: adding light calcium carbonate to deionized water according to the weight part, adding polycarboxylate sodium salt type dispersant during the dispersion process of starting the disperser, and then adding polyvinyl acetate emulsion in turn after dispersing for 25 minutes Adhesive, 11 parts of p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com