Antibacterial non-woven fabric, and preparation method and application thereof

A technology of non-woven fabrics and polypropylene non-woven fabrics, applied in textiles and papermaking, biochemical fiber treatment, fiber treatment, etc., to achieve good antibacterial effect, facilitate popularization and application, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

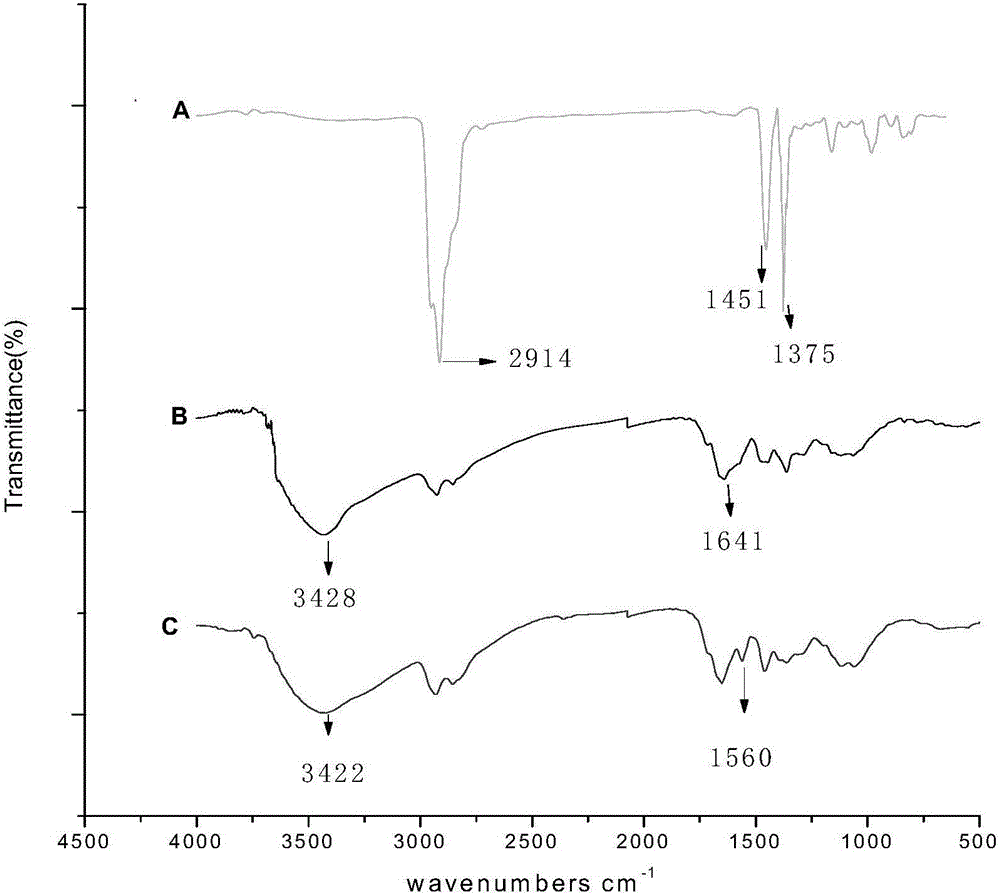

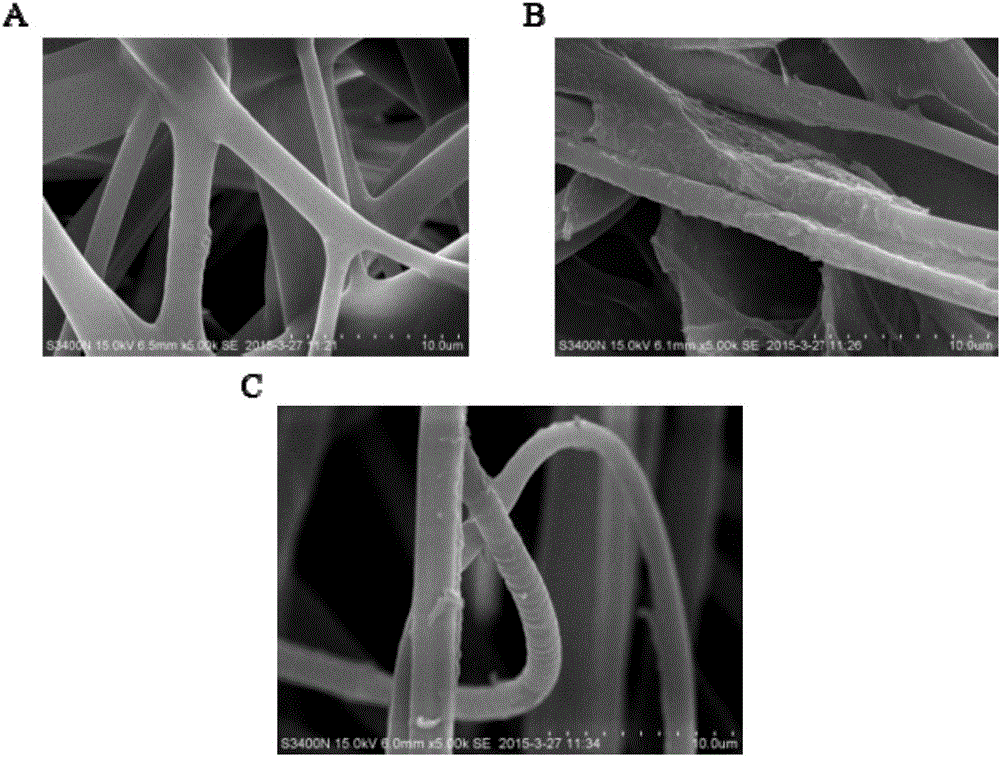

[0055] Cut the polypropylene non-woven fabric into a shape of 1cm×1cm, soak it in 3mol / L hydrochloric acid solution for 24 hours, take it out, wash it with deionized water several times until there is no hydrochloric acid residue, and dry it naturally in a ventilated place to remove the fabric sample. Impurities, oil stains and residual additives on the surface are stored in a desiccator for later use.

[0056] Dissolve aloe-emodin in absolute ethanol to prepare a 0.01 mg / mL emodin ethanol solution, and store it at 4°C for later use.

[0057] Place the spare polypropylene nonwoven fabric in a 5mL small bottle with a lid, add 1mL of 20% glutaraldehyde solution, shake in a water bath at 90°C at 150rpm for 120min, take it out and wash it with deionized water to dry. Then place it in 1mL polyethyleneimine solution with a volume fraction of 5%, shake in a 40°C water bath at 150rpm for 20min, remove the residual polyethyleneimine solution on the surface with deionized water, and dry...

Embodiment 2

[0061] Cut the polypropylene non-woven fabric into a shape of 1cm×1cm, place it in a 6mol / L hydrochloric acid solution and soak it for 24 hours, take it out, wash it with deionized water several times until there is no hydrochloric acid residue, and dry it to remove impurities, oil and dirt on the surface of the fabric sample. Residual additives are stored in a desiccator for later use.

[0062] Dissolve aloe-emodin in absolute ethanol to prepare a 0.002 mg / mL emodin ethanol solution, and store it at 4°C for later use.

[0063] Place the spare polypropylene nonwoven fabric in a 5mL small bottle with a lid, add 1mL glutaraldehyde solution with a volume fraction of 15%, shake it in a water bath at 70°C at 150rpm for 100min, take it out and wash it with deionized water to dry. Then place it in 1mL polyethyleneimine solution with a volume fraction of 6%, shake in a water bath at 30°C at 150rpm for 30min, remove the residual polyethyleneimine solution on the surface with deionized ...

Embodiment 3

[0065] Cut the polypropylene non-woven fabric into a shape of 1cm×1cm, soak it in 9mol / L hydrochloric acid solution for 24 hours, take it out, wash it with deionized water several times until there is no hydrochloric acid residue, and dry it to remove impurities, oil and dirt on the surface of the fabric sample. Residual additives are stored in a desiccator for later use.

[0066] Dissolve aloe-emodin in absolute ethanol to prepare a 0.005 mg / mL emodin ethanol solution, and store it at 4°C for later use.

[0067] Place the spare polypropylene nonwoven fabric in a 5mL small bottle with a lid, add 1mL glutaraldehyde solution with a volume fraction of 25%, shake it in a water bath at 80°C at 150rpm for 150min, take it out and wash it with deionized water to dry. Then place it in 0.5mL polyethyleneimine solution with a volume fraction of 15%, shake in a water bath at 50°C at 150rpm for 60min, remove the residual polyethyleneimine solution on the surface with deionized water, and d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com