Continuous biomass charcoal gas cogeneration device

A biomass charcoal, connected technology, applied in the fields of biofuels, special forms of dry distillation, direct heating dry distillation, etc., can solve the problems of low yield, high energy consumption, polluted water resources, etc., to reduce manufacturing costs and simple device structure. , the effect of reducing tar content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions of the present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

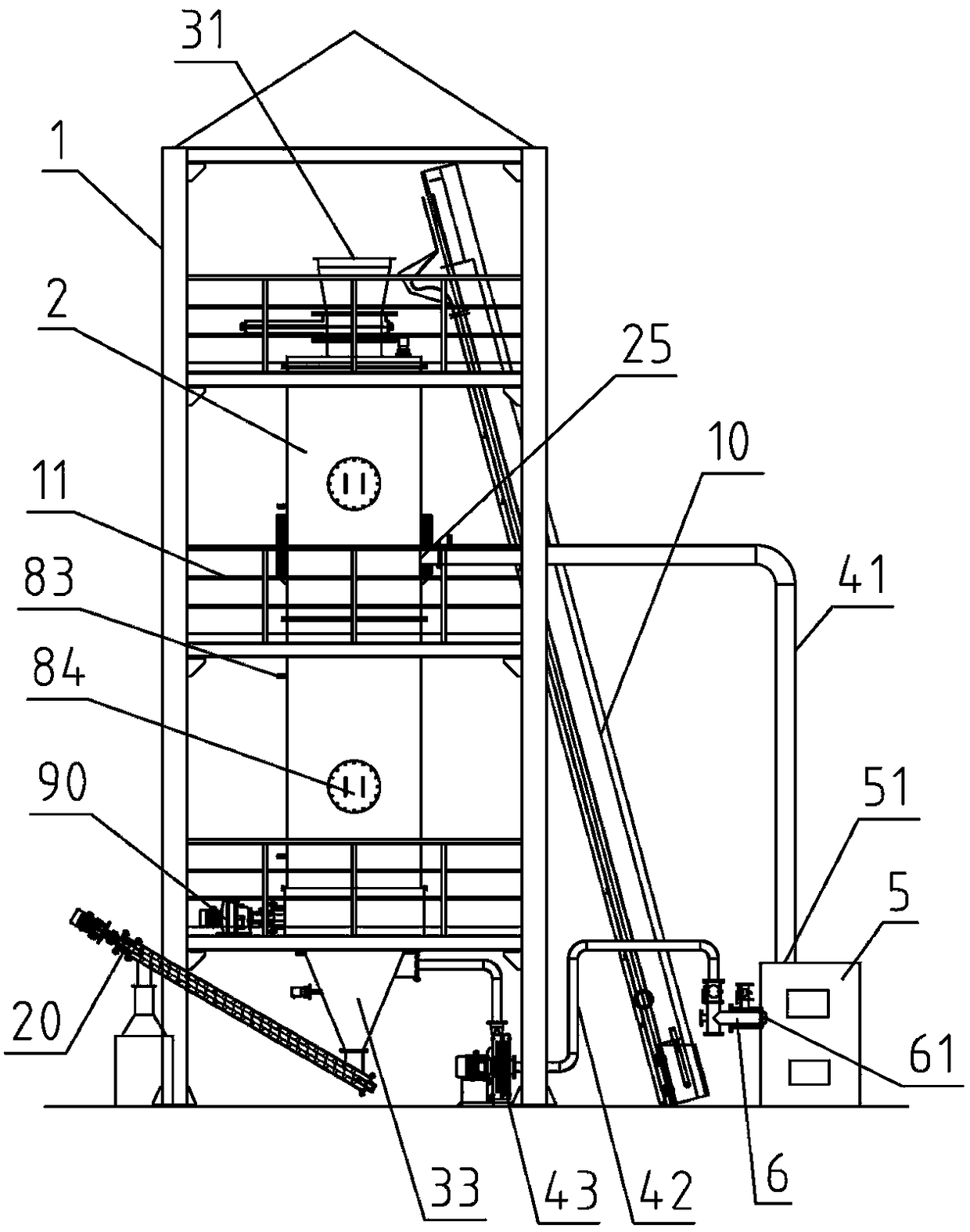

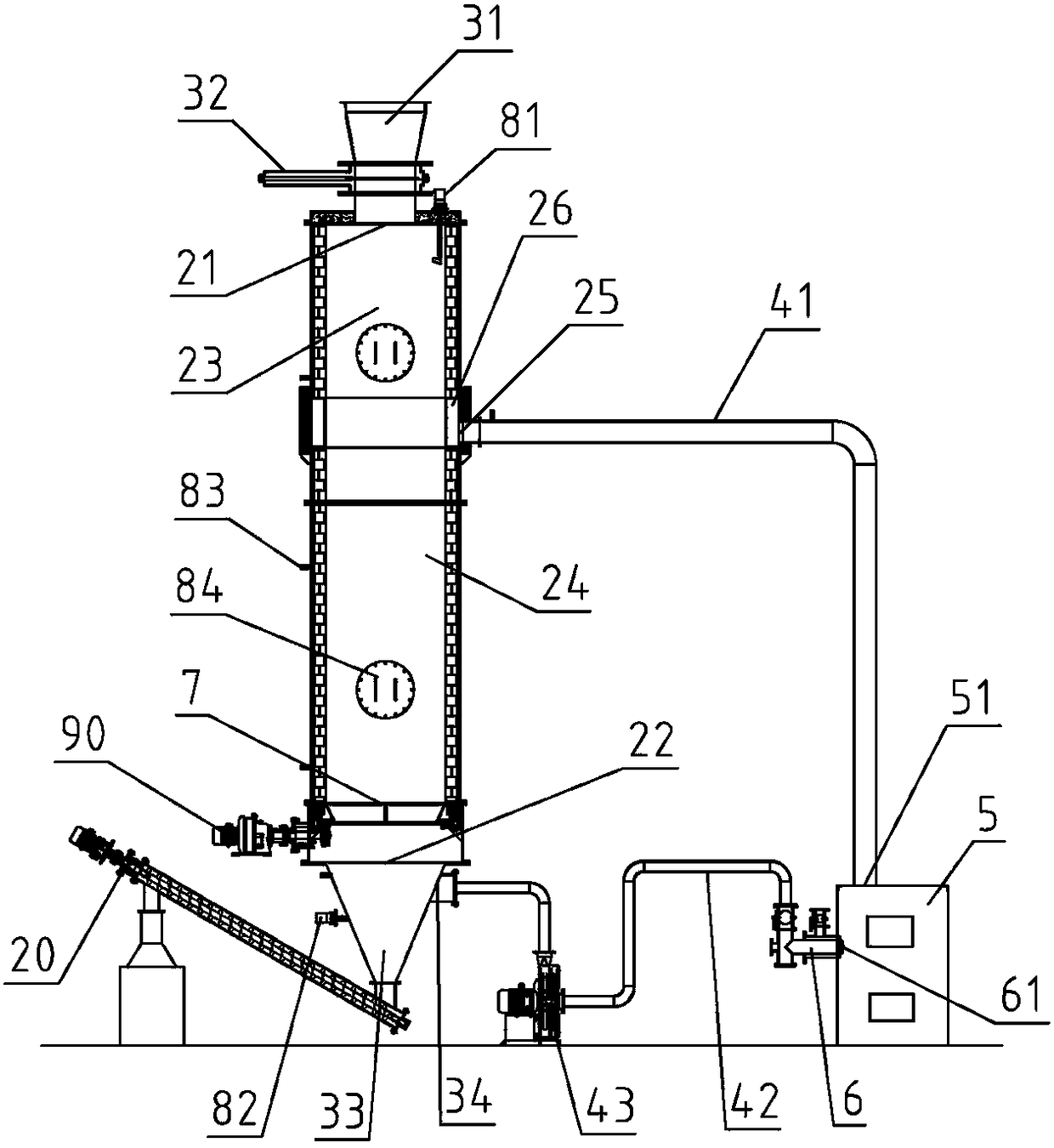

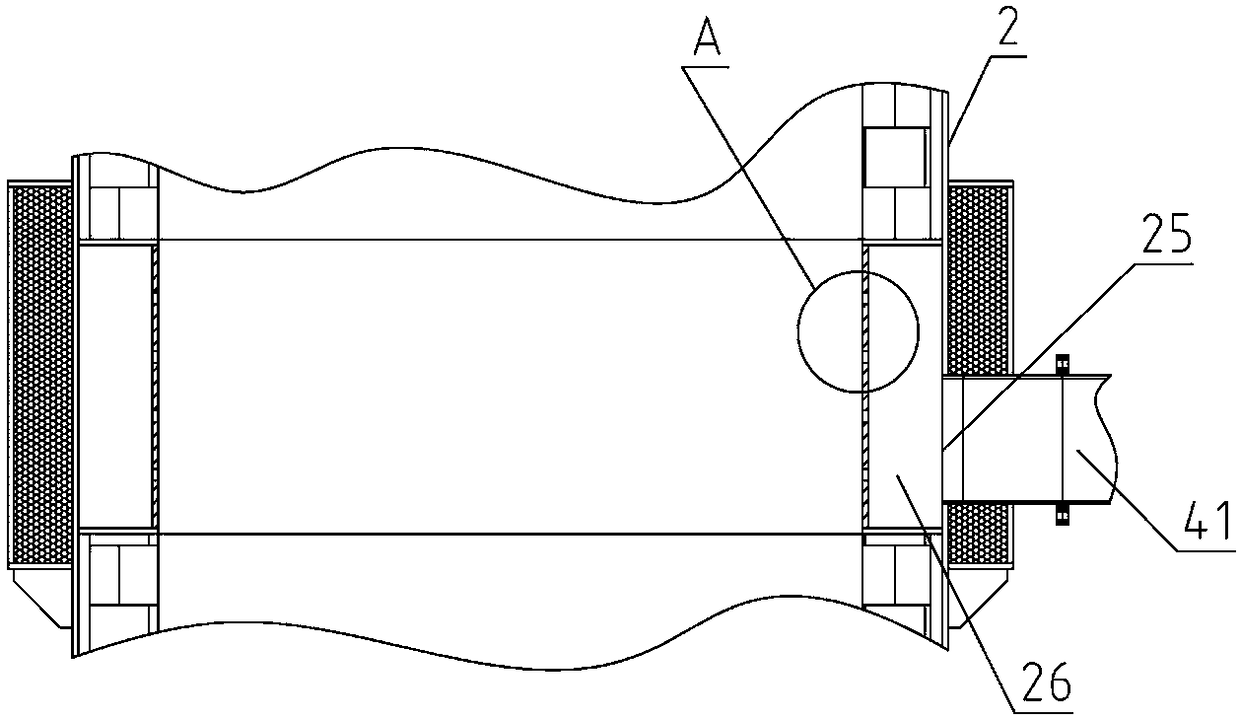

[0027] Such as figure 1 with figure 2As shown, the continuous biomass charcoal gas cogeneration device of the present invention includes: a support frame 1 and a furnace body 2 with an inner cavity, the furnace body 2 is arranged on the support frame 1, and the top of the furnace body 2 is provided with Feed port 21 and feed hopper 31, feed hopper 31 is connected with the feed port 21 of furnace body 2 through gate valve 32, is provided with discharge port 22 and is communicated with discharge port 22 at the bottom of furnace body 2 Unloading hopper 33. During actual use, several platforms 11 are arranged at intervals from bottom to top on the support frame 1 , and a ladder capable of reaching any platform 11 is also provided on the support frame 1 . The inner cavity of the furnace body 2 is provided wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com