A high-temperature-resistant low-toxicity hammer spray paint and preparation method thereof

A technology of high temperature resistance and hammer pattern, which is applied in the field of high temperature resistant and low toxicity hammer pattern spray paint and its preparation, can solve the problems of unmentioned hammer pattern paint color stability, unmentioned technical effect, non-compliance with low toxicity and environmental protection, etc. Achieve the effect of improving product smell, moderate pattern size and strong three-dimensional effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

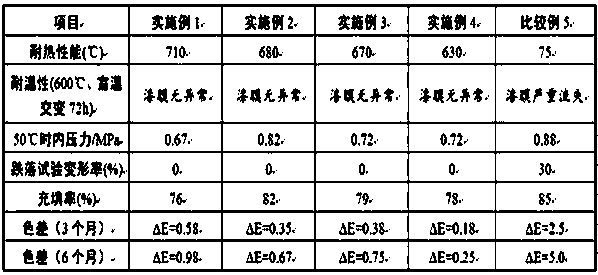

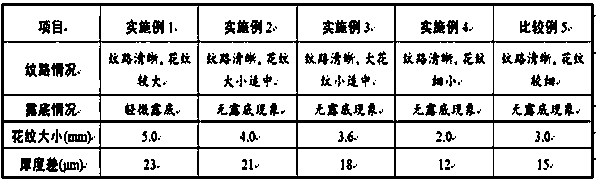

Examples

Embodiment 1

[0047] 1) Aluminum silver paste pretreatment: according to the proportion by weight, add 1 / 5 solvent (18 parts of sec-butyl acetate, 1.44 parts of propylene glycol butyl ether, 8 parts of methyl ethyl ketone, 12 parts of cyclohexane) into the container, slowly Add 2 parts of non-leafing aluminum-silver paste (particle size: 10 μm), stir evenly, soak for 12 hours, and stir again before use;

[0048] 2) Preparation of paint material: Add 27 parts of alkyd modified silicone resin and 0.3 parts of BYK-AT204 into the reaction tank according to the weight ratio, start the machine and stir evenly, add 4 parts of high temperature resistant iron red, 0.5 parts of high temperature resistant iron black 1 part, 0.5 part of high temperature resistant titanium nickel yellow, 2 parts of nano-graphene treated with silane coupling agent and 6 parts of diamond-type boron nitride are slowly added to the reaction tank, stirred until there are no obvious particles by visual inspection, and then san...

Embodiment 2

[0051] 1) Aluminum silver paste pretreatment: according to the proportion by weight, add 1 / 4 solvent (27 parts of sec-butyl acetate, 1.09 parts of propylene glycol butyl ether, 10 parts of methyl ethyl ketone, 12 parts of cyclohexane) into the container, slowly Add 3 parts of non-leafing aluminum silver paste (particle size 12μm or 13μm), stir well and then soak for 15h, stir again before use;

[0052] 2) Preparation of paint material: Add 22 parts of polyurethane modified silicone resin and 0.6 part of Disperbyk-163 into the reaction tank according to the weight ratio, start the machine and stir evenly, add 2 parts of high temperature resistant molybdenum chrome red, high temperature resistant permanent purple 0.8 parts, 0.2 parts of high-temperature-resistant rutile titanium dioxide, 1 part of nano-graphene treated with silane coupling agent and 3 parts of diamond-type boron nitride are slowly added to the reaction tank, stirred until there are no obvious particles by visual ...

Embodiment 3

[0055] 1) Aluminum silver paste pretreatment: according to the proportion by weight, add 1 / 5 solvent (28 parts of sec-butyl acetate, 1.55 parts of propylene glycol butyl ether, 8 parts of methyl ethyl ketone, 13 parts of cyclohexane) into the container, slowly Add 4 parts of non-leafing aluminum silver paste (particle size 14μm or 15μm), stir well, soak for 24 hours, and stir again before use;

[0056] 2) Preparation of paint material: Add 21 parts of acrylic modified silicone resin and 0.5 part of Disperbyk-163 into the reaction tank according to the proportion by weight, start the machine and stir evenly, add 2 parts of high-temperature-resistant copper chrome black (or high-temperature-resistant phthalocyanine green 0.5 parts, 1 part of high-temperature-resistant phthalocyanine blue, 0.5 parts of high-temperature-resistant copper chromium black), 1 part of nano-graphene treated with silane coupling agent and 4 parts of diamond-type boron nitride were slowly added to the reac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com