Temperature control sponge and preparation method thereof

A sponge and raw material technology, applied in the field of temperature control sponge and its preparation, can solve the problems of poor washing resistance, strict requirements for subsequent processes, poor continuity of temperature control effect, etc., and achieve the effect of uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A temperature-control sponge prepared by weight with the following components,

[0032] 70 parts of polyether polyol, 30 parts of grafted polyether, 50 parts of toluene diisocyanate, 0.3 parts of triethylene diamine, 0.28 parts of stannous octoate, 1.5 parts of silicone oil, 1 part of methylene chloride, 3 parts of flame retardant, aromatic Family chain extender HQEE 2 parts, water 3.5 parts, white wax 5 parts.

[0033] The specific steps of the preparation method are as follows:

[0034] 1) Heat the white wax into a liquid, then add the aromatic chain extender HQEE, mix it evenly and keep it at 60°C;

[0035] 2) Mix the remaining raw materials uniformly and control the temperature at 28°C;

[0036] 3) Mix the mixture of step 1) and step 2) together, and stir the reaction at a stirring speed of 3000-4000 revolutions / min;

[0037] 4) After the reaction is completed, it is naturally cooled to 35°C and kept at this temperature and a relative humidity of 60% for 24 hours.

Embodiment 2

[0039] 75 parts of polyether polyol, 25 parts of grafted polyether, 60 parts of toluene diisocyanate, 0.45 parts of triethylene diamine, 0.45 parts of stannous octoate, 1.9 parts of silicone oil, 3 parts of methylene chloride, 4 parts of flame retardant, aromatic Family chain extender HQEE 3 parts, water 4 parts, white wax 8 parts.

[0040] The preparation method is the same as in Example 1.

Embodiment 3

[0042] 80 parts of polyether polyol, 20 parts of grafted polyether, 65 parts of toluene diisocyanate, 0.6 parts of triethylene diamine, 0.6 parts of stannous octoate, 2.3 parts of silicone oil, 5 parts of methylene chloride, 5 parts of flame retardant, aromatic Family chain extender HQEE 4 parts, water 4.5 parts, white wax 10 parts.

[0043] The preparation method is the same as the example.

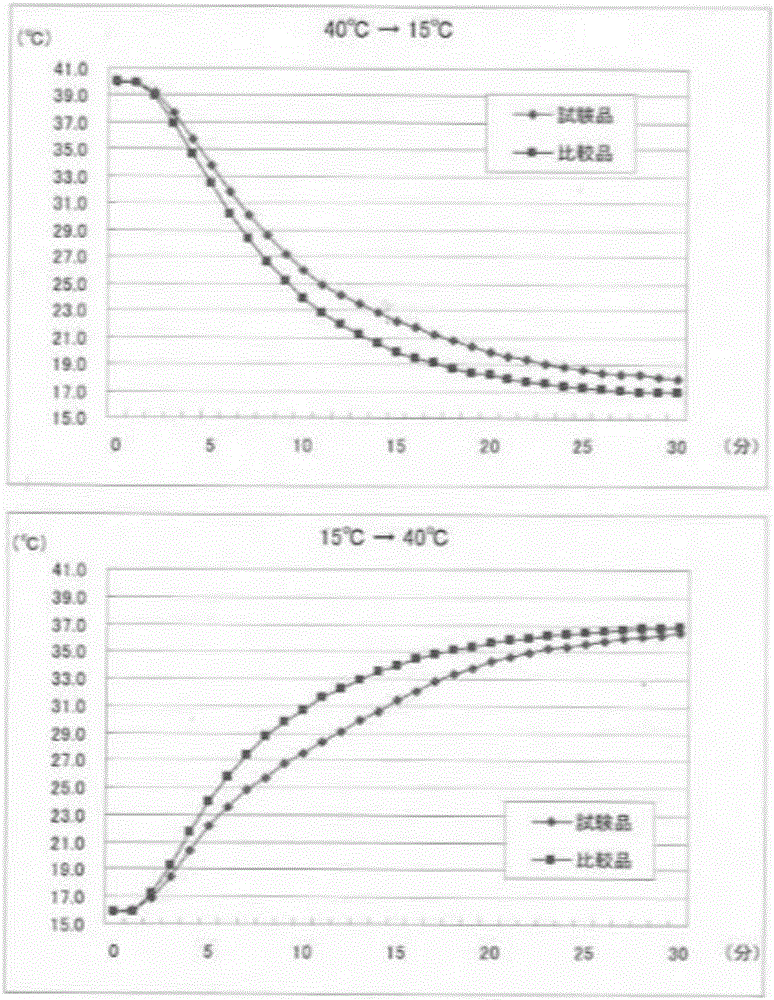

[0044] The temperature control sponge prepared in Example 2 was tested for the temperature control effect, and the test results are as follows figure 1 As shown, the comparison product in the test is an ordinary sponge with the same density; description: figure 1 It can be seen that the temperature control sponge of the present invention can effectively suppress temperature changes, and its curve is relatively gentle, reflecting that when the temperature rises, the temperature control sponge has a slower heating speed, can be maintained at 27 degrees Celsius for a period of time, and will al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com