Low-molecular-weight polyglutamic acid, and preparation method and application thereof

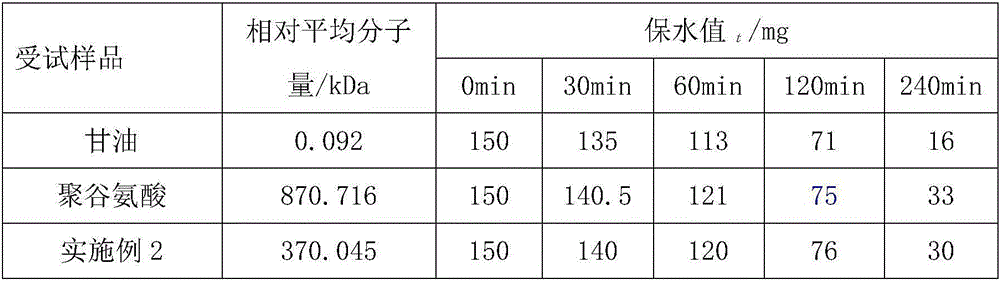

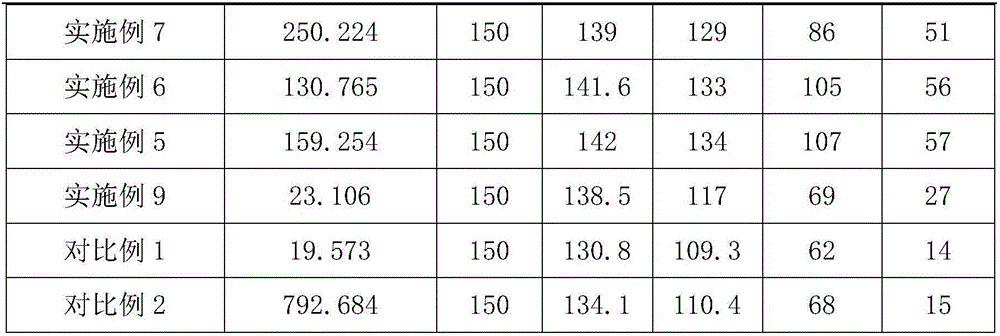

A technology of polyglutamic acid and low molecular weight, which is applied in the field of low molecular weight polyglutamic acid and its preparation, can solve problems such as lack of targeted exploration, reduce the risk of clogging skin pores and sweat glands, and have excellent moisturizing performance , skin delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: Preparation of low molecular weight polyglutamic acid

[0038] Degradation is carried out with a polyglutamic acid aqueous solution with a concentration of 1% (w / v) as a reaction substrate. The degradation conditions are: pH 4.0, temperature 60°C, and holding time 1h to obtain a degradation product; add an alcohol reagent to the degradation product, When the alcohol content reaches 65% (w / w), a precipitate is formed, which is collected and dried to obtain low molecular weight polyglutamic acid.

[0039] Wherein, the aqueous solution of polyglutamic acid is an aqueous solution of sodium polyglutamate, and the relative average molecular weight of polyglutamic acid is 500 kDa. The alcohol reagent is ethanol.

Embodiment 2

[0040] Embodiment 2: Preparation of low molecular weight polyglutamic acid

[0041]Degradation is carried out with a polyglutamic acid aqueous solution with a concentration of 1.5% (w / v) as a reaction substrate. The degradation conditions are: pH 6.0, temperature 70°C, and holding time 3 hours to obtain a degradation product; add alcohol reagent to the degradation product, When the alcohol content reaches 80% (w / w), a precipitate is formed, which is collected and dried to obtain low molecular weight polyglutamic acid.

[0042] Wherein, the aqueous solution of polyglutamic acid is an aqueous solution of sodium polyglutamate, and the relative average molecular weight of polyglutamic acid is 700 kDa. The alcohol reagent is ethanol.

Embodiment 3

[0043] Embodiment 3: the preparation of low molecular weight polyglutamic acid

[0044] The aqueous solution of polyglutamic acid with a concentration of 2.0% (w / v) was used as the reaction substrate for degradation. The degradation conditions were: pH 5.0, temperature 68°C, and holding time 1.8 hours to obtain the degradation product; add alcohol reagent to the degradation product , so that the alcohol content reaches 68% (w / w), a precipitate is generated, and the precipitate is collected and dried to obtain low molecular weight polyglutamic acid.

[0045] Wherein, the aqueous solution of polyglutamic acid is an aqueous solution of sodium polyglutamate, and the relative average molecular weight of polyglutamic acid is 800 kDa. The alcohol reagent is ethanol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com