Method for treating cassava alcohol wastewater through anaerobic reactor filled with ceramic material

An anaerobic reactor and cassava alcohol technology, which is applied in anaerobic digestion treatment, chemical instruments and methods, natural water treatment, etc., can solve energy consumption and other problems, and achieve high efficiency, resource utilization value, and high methane production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Below in conjunction with accompanying drawing, the specific embodiment of the present invention is described in detail:

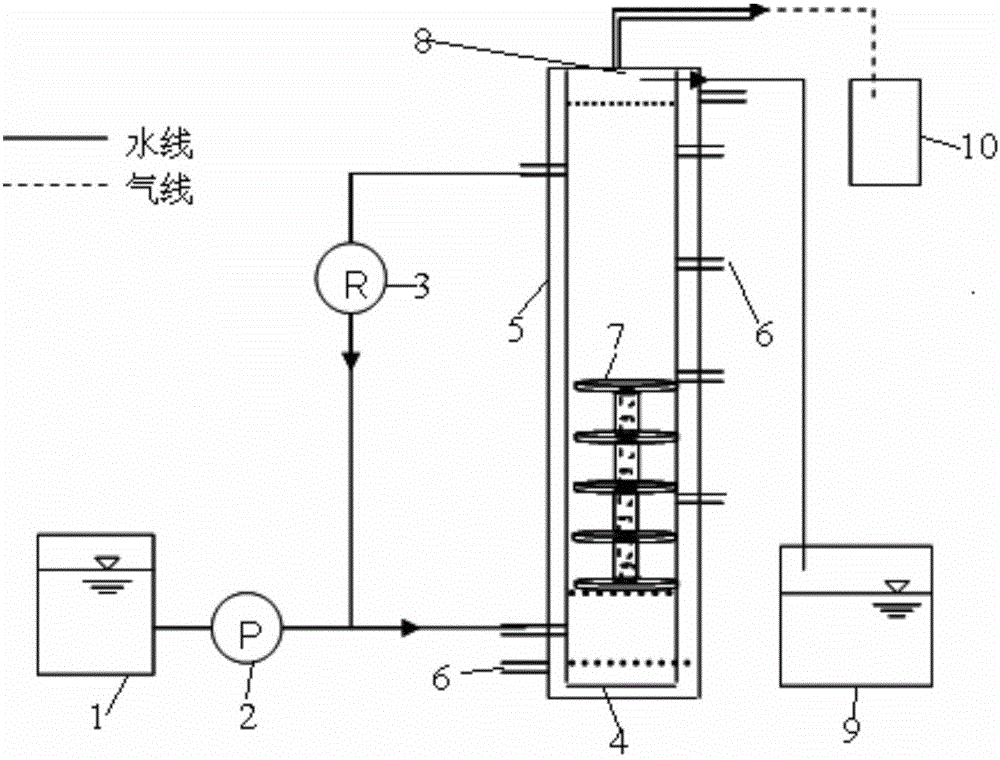

[0043] A kind of method that ceramic material fills anaerobic reactor to process cassava alcohol waste water, comprises the steps:

[0044] 1) Fill the ceramic material into the anaerobic reactor, which is designed by ourselves and manufactured by Jiangsu Nanjing Gongda Yuankai Bioenergy Environmental Technology Co., Ltd., with a total volume of 3460 cm 3 , the size of the ceramic material L×D×H is 18×18×18 mm, and the total volume of the porous ceramic carrier accounts for 35% to 40% of the volume of the anaerobic bioreactor;

[0045] 2) Inoculate 865-1142 mL of anaerobic sludge on the ceramic carrier in the reactor, and use artificial wastewater for cultivation during the static cultivation stage of the sludge. The formula is 0.25 g / L of sodium acetate and 0.25 g / L of sodium propionate , sodium butyrate 0.25 g / L, urea 0.5 g / L, glucose 0.25 g / L, d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com