Plastic bottle processing device for even forming

A technology for processing equipment and plastic bottles, which is applied in the field of plastic bottle molding, and can solve the problems of quality impact of finished products, inability to quickly cool down equipment life, and mixing of people

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

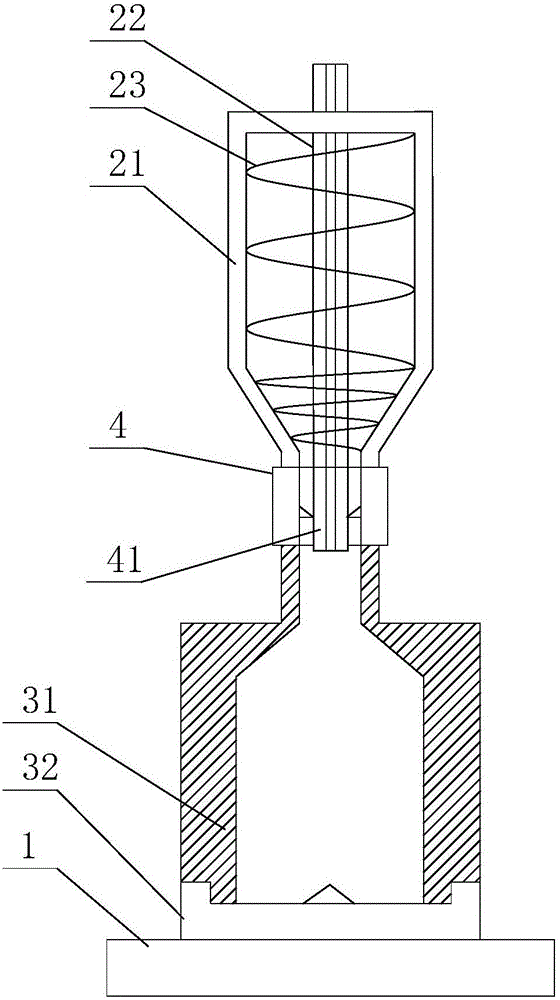

[0015] Such as figure 1 as shown, figure 1 It is a structural schematic diagram of a uniformly formed plastic bottle processing equipment proposed by the present invention.

[0016] refer to figure 1 , a uniformly formed plastic bottle processing equipment proposed by the present invention, comprising: a base 1, a feeding device, a mold assembly, a cutting device 4, a first driving device, and a second driving device;

[0017] Mold assembly comprises patrix 31, mold base 32, and mold base 32 is rotatably installed on the base 1 and its rotating shaft is vertically arranged, and the first driving device is connected with mold base 32 and is used to drive mold base 32 to rotate, and upper mold 31 is positioned at mold base. Above the base 32, a vertically extending molding cavity is formed between the upper mold 31 and the mold base 32, and the top of the molding cavity is provided with a first feed port;

[0018] The cutting device 4 is located above the upper mold 31, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com