Heavy bamboo composite board

A composite board, bamboo board technology, applied in the direction of floor covering, wood veneer bonding, synthetic resin layered products, etc., can solve the problems of corrosion, damage, poor dimensional stability of reconstituted bamboo materials, etc. Production cost reduction and thickness reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0099] The preparation method of heavy bamboo composite board comprises the following preparation steps:

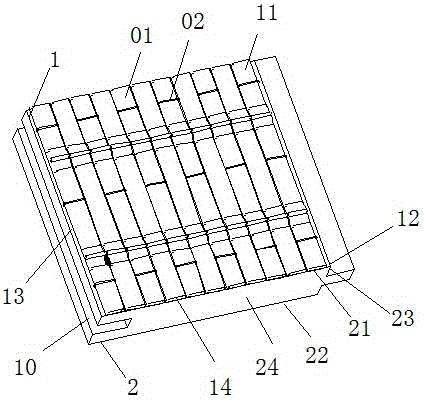

[0100] (1) Bamboo panel prefabrication: the bamboo fiber strip connector 02 with strength in the non-parallel direction of the bamboo fiber strip is woven across the bamboo fiber strip 01 with a thickness of 1 mm and a width of 1 mm to form a bamboo fiber strip weaving curtain; the bamboo fiber strip The width of the woven curtain is 0.6m;

[0101] (2) Drying: send the prefabricated bamboo board surface board into drying until the moisture content is 6%, and obtain the bamboo board surface board drying board;

[0102] (3) Base plate preparation;

[0103] (4) Hot pressing: Apply thermosetting resin glue on the bottom of the bamboo board surface or the top of the bamboo board bottom board, place the bamboo board surface drying board on the top of the bamboo board bottom board, and press the pressure 3MPa / cm 2 1. Hot pressing at 170° C. for hot pressing for 20 minutes to o...

Embodiment 2

[0107] The preparation method of heavy bamboo composite board comprises the following preparation steps:

[0108] (1) Bamboo board surface prefabrication: Weave the bamboo fiber strip connector 02 with strength in the non-parallel direction of the bamboo fiber strip across the bamboo fiber strip 01 with a thickness of 4 mm and a width of 10 mm to form a bamboo fiber strip weaving curtain, and the bamboo fiber The strip woven curtain is impregnated with the first thermosetting resin to obtain the prefabricated panel of the bamboo board surface; the width of the bamboo fiber strip woven curtain is 2m;

[0109] (2) Drying: send the prefabricated bamboo board surface board into drying until the moisture content is 10%, and obtain the bamboo board surface board drying board;

[0110] (3) Base plate preparation;

[0111] (4) Hot pressing: Place the drying board of the bamboo board on the top of the bamboo board, and press the hot pressing pressure 6MPa / cm 2 1. Hot pressing at 120°...

Embodiment 3

[0115] The preparation method of heavy bamboo composite board comprises the following preparation steps:

[0116] (1) Bamboo board surface prefabrication: Weave the bamboo fiber strip connector 02 with strength in the non-parallel direction of the bamboo fiber strip across the bamboo fiber strip 01 with a thickness of 2mm and a width of 15mm to form a bamboo fiber strip weaving curtain, and the bamboo fiber strip The strip woven curtain is impregnated with the first thermosetting resin to obtain the prefabricated panel of the bamboo board surface; the width of the bamboo fiber strip woven curtain is 1.5m;

[0117] (2) Drying: send the prefabricated bamboo board surface board into drying until the moisture content is 8%, and obtain the bamboo board surface board drying board;

[0118] (3) Base plate preparation;

[0119] (4) Hot pressing: Place the drying board of the bamboo board on the top of the bamboo board, and press it at a pressure of 5MPa / cm 2 1. Hot pressing at 140° ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com