Corn double-line width ridge deep ploughing layering fertilizing seeder

A layered fertilization and seeder technology, applied in agricultural machinery and implements, shovels, plows, etc., can solve problems such as poor lighting and ventilation, increased operating costs, and lack of mechanized equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

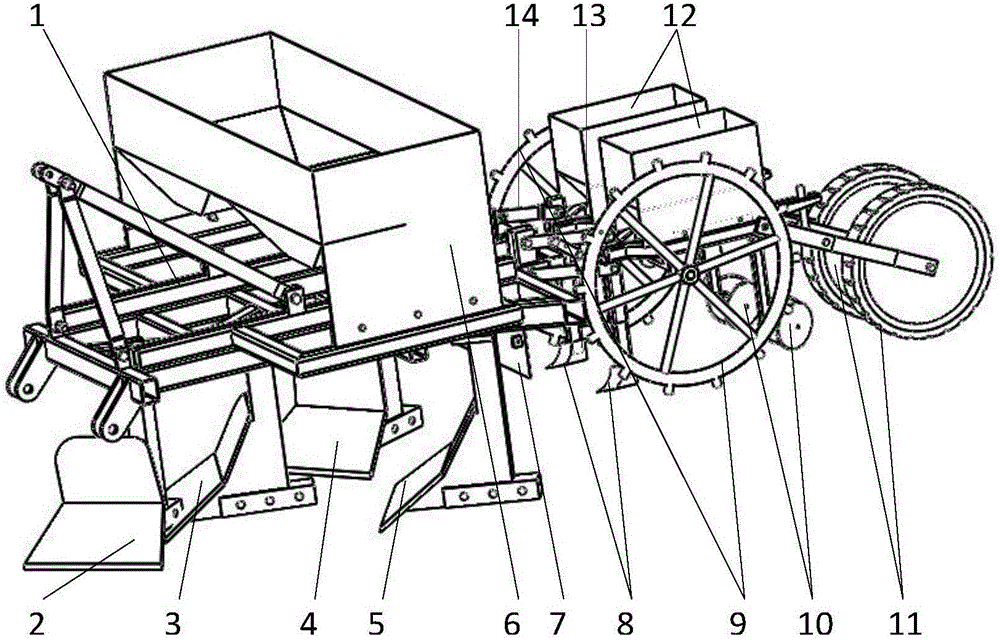

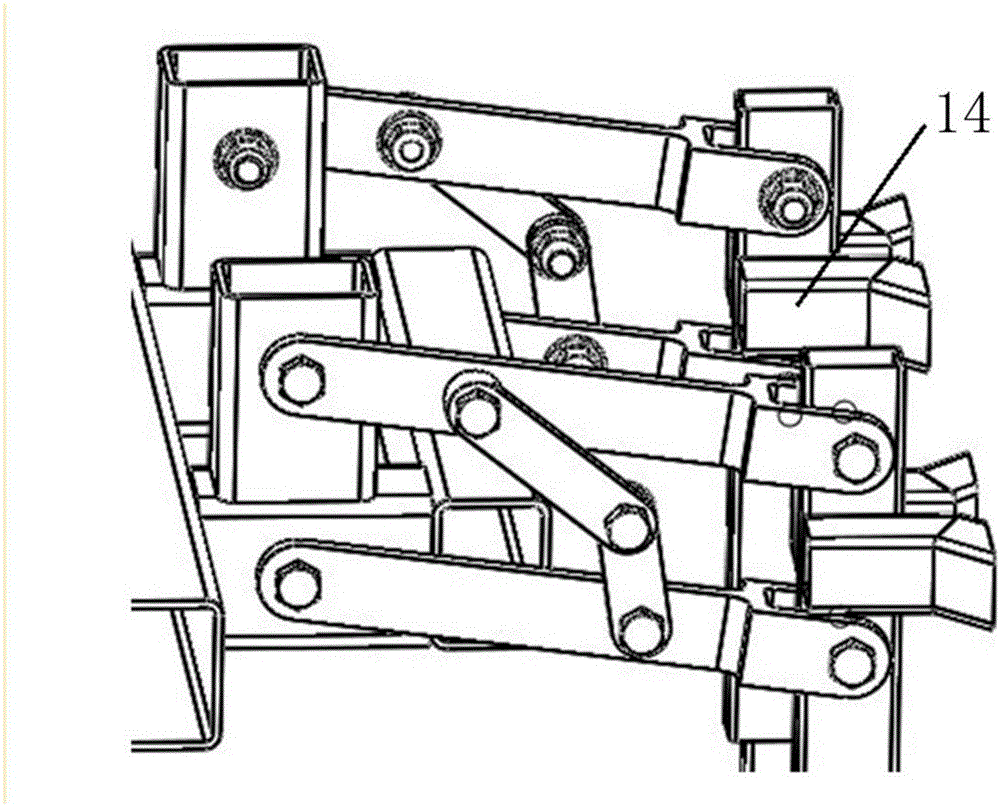

[0035] A deep plowing and layered fertilization seeder for large corn ridges, comprising a deep plowing layered fertilization device and a ridge adjustment device on the front side, a parallel four-bar connecting part 14 in the middle and a precision seeding device on the rear side;

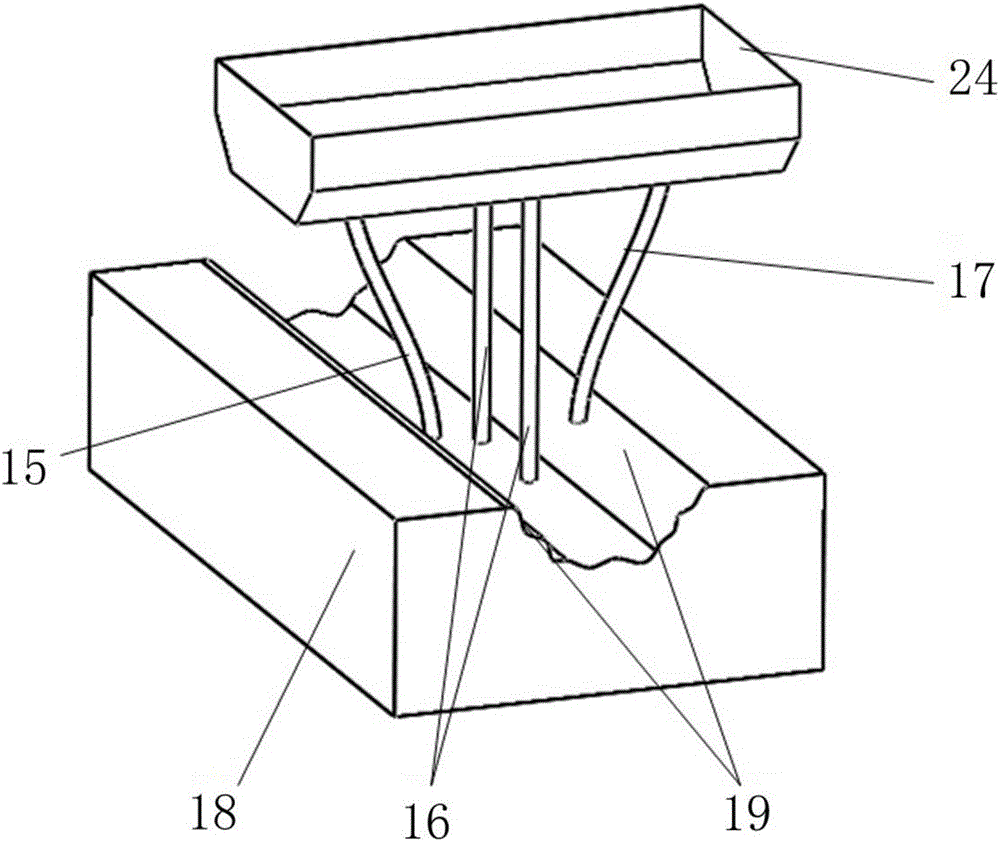

[0036] The described deep tillage and layered fertilization device comprises a front frame 1, a pair of furrow plows, a pair of soil-covering ridge plows, and a fertilizer box 6. The pair of furrow plows is composed of a left furrow plow 2 and a left furrow plow with the same structure. The right furrow plow 3 is formed, and the left furrow plow 2 and the right furrow plow 3 are installed in the front and rear of the front frame 1 in a staggered manner through a furrow plow support respectively in the forward direction of the planter. A pair of furrow plows The plow surfaces of the plows are all set outward, so that the plowing resistance is opposite to the forward direction of the unit, so as to ...

Embodiment 2

[0043] A deep plowing and layered fertilization seeder for large corn ridges, comprising a deep plowing layered fertilization device and a ridge adjustment device on the front side, a parallel four-bar connecting part 14 in the middle and a precision seeding device on the rear side;

[0044] The subsoiling and layered fertilization device comprises a front frame 1, a pair of furrowing plows, a pair of covering soil ridge closing plows, and a fertilizer box 6, and the pair of furrowing plows is formed by a left furrowing plow 2 with the same structure. It is formed with the right furrow plow 3, and the left furrow plow 2 and the right furrow plow 3 are respectively installed under the front frame 1 in a staggered manner in the forward direction of the planter through a furrow plow bracket. The plow faces of the plows are all set outward, so that the plowing resistance is opposite to the forward direction of the unit, so as to avoid excessive lateral force. During the operation, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com