Butterfly optical cable

A butterfly optical cable and main component technology, applied in the field of optical fiber cable production, can solve the problems of short service life, weak ability to protect optical fibers, and easy water seepage, and achieve short service life, weak ability to protect optical fibers, and good pressure resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

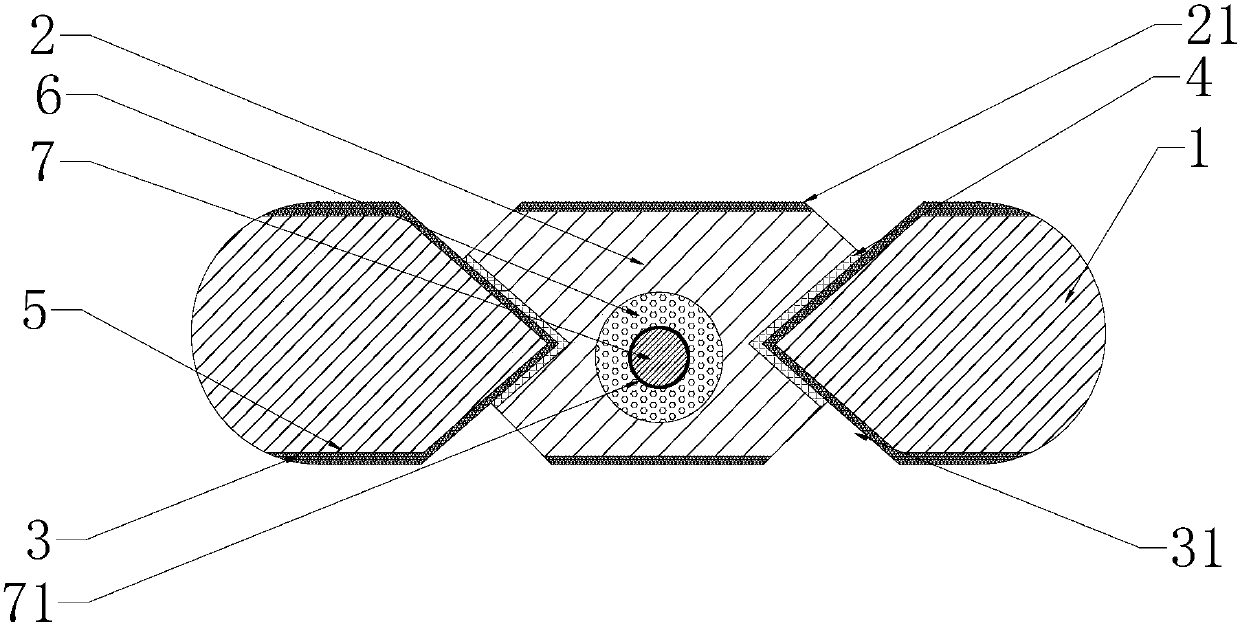

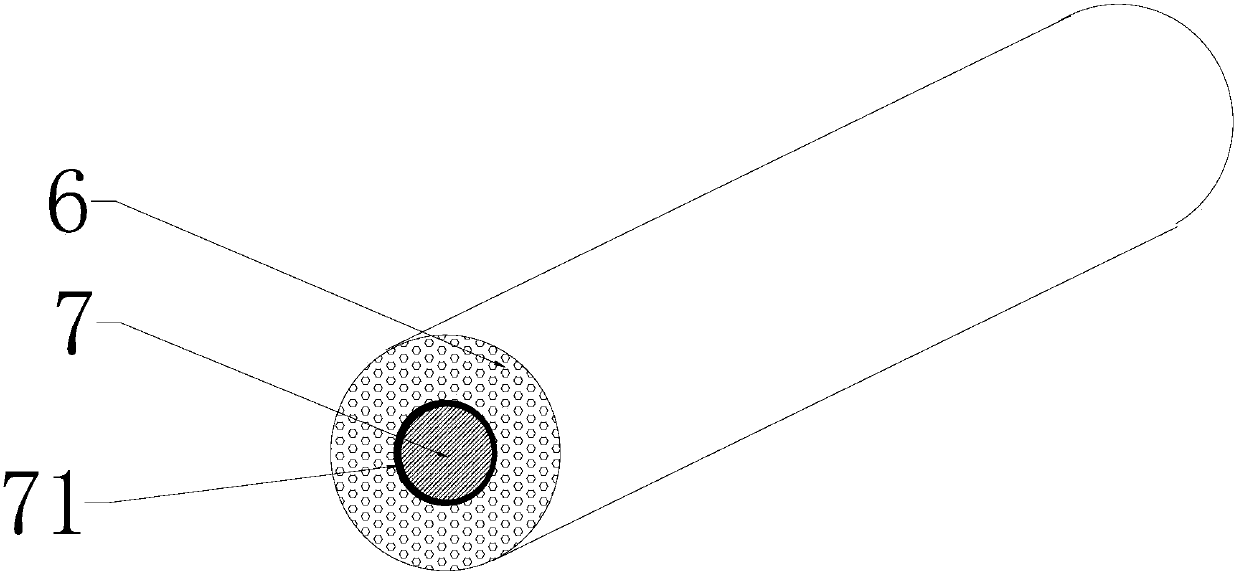

[0021] The invention discloses a butterfly optical cable (see attached figure 1 , 2 ), including: a pair of reinforcing pieces 1 and a main piece 2, the pair of reinforcing pieces 1 are respectively arranged on both sides of the main piece 2; The edge 3 is connected with the main part 2 through the adhesive layer 4, the sharp edge 3 protrudes to the inside of the main part 2, the sharp edge 3 is connected to the extension part 5, and the extension part 5 covers the outer surface of the reinforcement part 1 ; The sharp edge 3 and the extension 5 are made of pressure-resistant materials; the main part 2 is provided with a foam layer 6, and the foam layer 6 is made of a foam material, and the foam material is filled with nitrogen, nitrogen The pressure is greater than or equal to 1.5 standard atmospheric pressure, the optical fiber 7 is arranged in the foam layer 6 ; the radial height of the main part 2 is less than or equal to the radial height of the reinforcement part 1 . In...

Embodiment 2

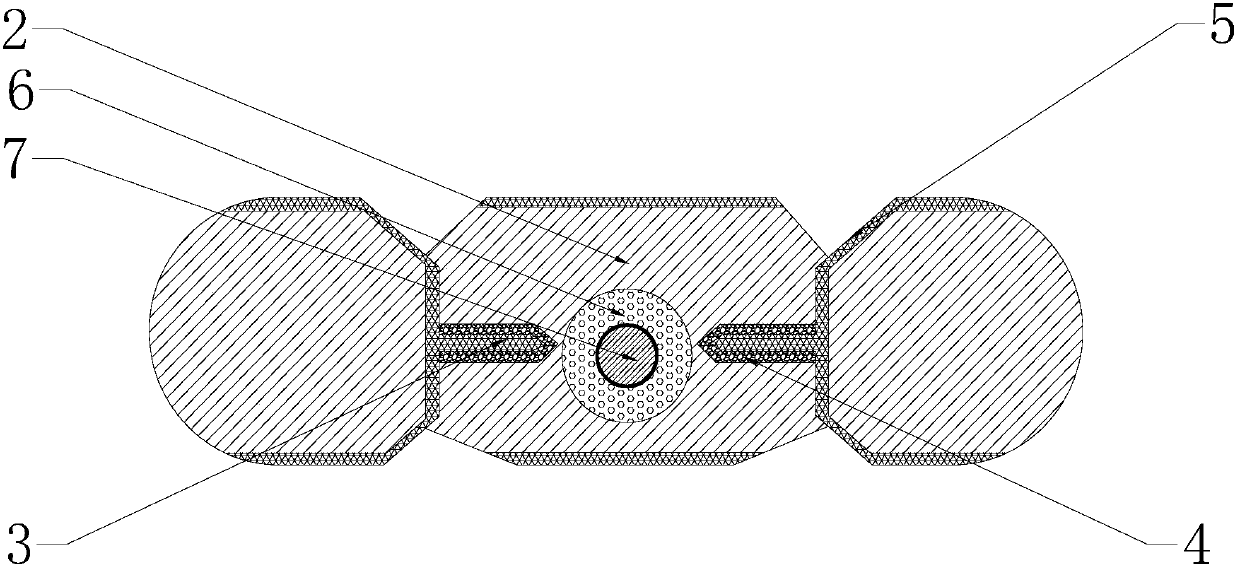

[0025] The sharp edge 3 is a rod-shaped structure on the protruding section, and the tip of the sharp edge 3 has a beak (see attached image 3 ), the pointed edge 3 is connected to the main part 2 through the adhesive layer 4 . The adhesive layer 4 is other materials with low density and low adhesive strength.

[0026] When implementing the embodiment of the present invention, hold the two ends of the reinforcing piece, apply force to the left and right respectively, separate the reinforcing piece and the main piece, obtain deep openings on both sides of the main piece, peel off the insulating material on the main piece from the opening, and finally simply peel off the hair. Bubble material to get bare fiber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com