Rubber bearing life test clamp

A rubber bearing and life test technology, applied in the testing of mechanical components, testing of machine/structural components, measuring devices, etc., can solve problems such as load application, and achieve easy disassembly, convenient installation, and ingenious and compact overall structure design. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

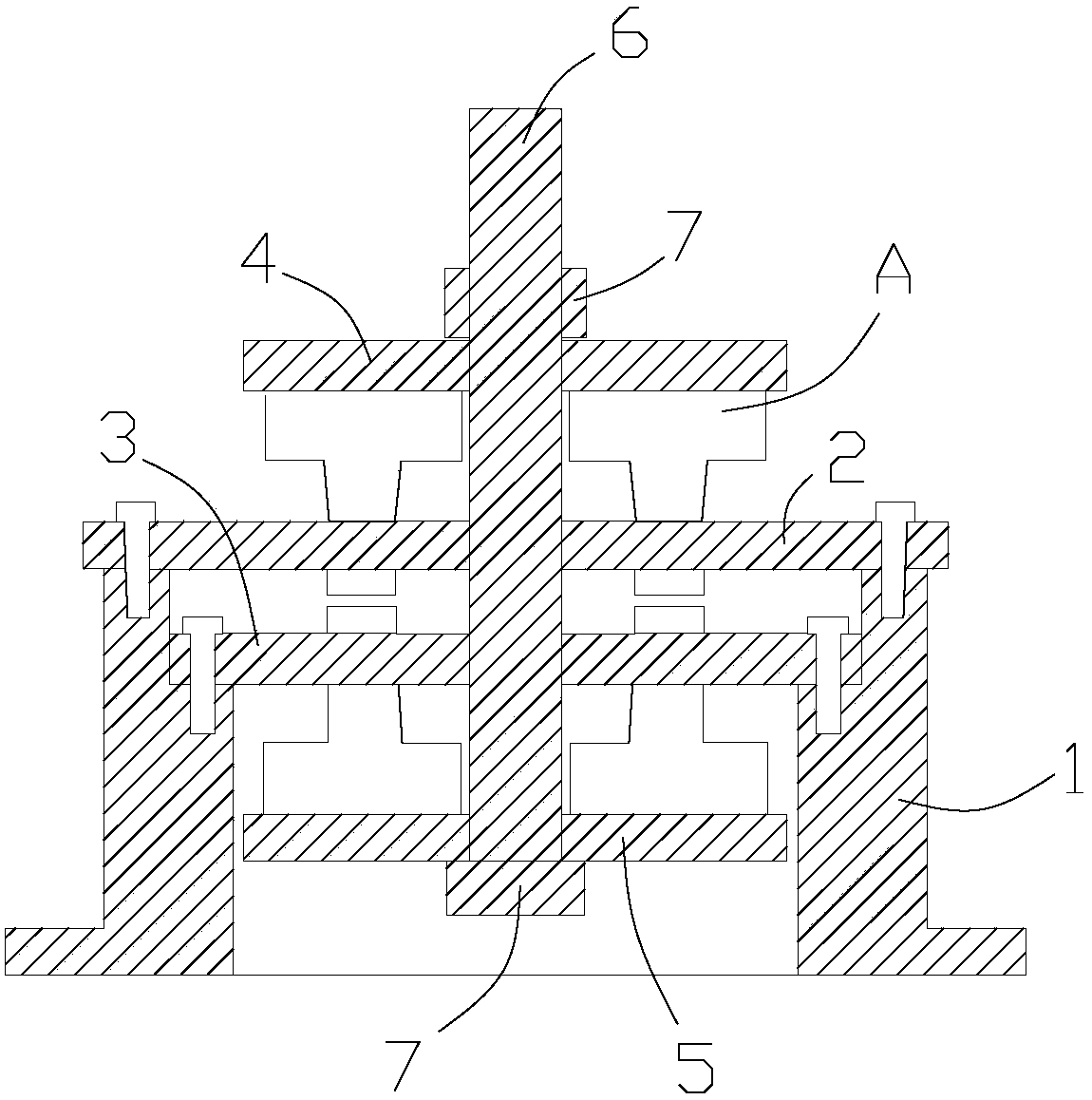

[0012] refer to figure 1 , the rubber bearing life test fixture of the present invention is mainly composed of a base body 1, a first fixed base plate 2, a second fixed base plate 3, a first movable base plate 4, a second movable base plate 5, a dynamic loading bolt 6 and a static load preload Nut 7 composition. When in use, the dynamic loading bolt 6 is connected to the actuator of the universal testing machine, and the base 1 is fixed to the fixed end of the universal testing machine. During testing, the actuator drives the dynamic loading bolt 6 to move up and down relative to the base 1 for testing.

[0013] The base 1 is provided with a hollow cavity, and the first variable substrate 4 , the first fixed substrate 2 , the second fixed substrate 3 and the second movable substrate 5 are arranged in the hollow cavity in layers from top to bottom. The outer edges of the first fixed substrate 2 and the second fixed substrate 3 are fixed on the base body 1 , so the positions of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com